Lean Six Sigma in Manufacturing: Guide to Implementation and Success

Manufacturing plants implementing Lean Six Sigma have reported up to 70% reduction in production cycle times and 50% decrease in manufacturing costs.

These aren’t just impressive numbers—they represent real transformation in how factories operate and compete in today’s market.

Transform your manufacturing operations with proven methodologies and expert guidance

Master the fundamentals of Lean and Six Sigma with our comprehensive Lean Six Sigma Green Belt Certification.

Lean Six Sigma in manufacturing combines two powerful methodologies to create a systematic approach for eliminating waste and reducing variation in production processes.

It merges Lean’s focus on efficiency and flow with Six Sigma’s emphasis on consistency and defect reduction.

For manufacturing operations, this marriage of methodologies delivers a practical framework to boost quality while cutting costs.

Key Highlights

- DMAIC framework for solving manufacturing problems

- Essential tools for production improvement

- Implementation steps for factory settings

- Real success stories with measurable results

Understanding Lean Six Sigma in Manufacturing

Lean Six Sigma represents a powerful fusion of two distinct methodologies that have transformed the manufacturing industry over the past few decades.

This approach combines Lean’s waste elimination principles with Six Sigma’s focus on reducing process variation to create a more robust improvement framework than either methodology alone.

When applied to manufacturing settings, Lean Six Sigma provides a structured pathway to enhance production processes while maintaining strict quality standards.

Definition and core principles

The core principles of Lean Six Sigma in manufacturing revolve around five key elements: customer focus, identifying value streams, creating flow, establishing pull, and pursuing perfection.

These principles guide manufacturing teams to eliminate activities that don’t add value to the final product while ensuring consistent quality output that meets customer specifications.

Difference between Six Sigma and Lean Manufacturing

Many manufacturing professionals confuse Six Sigma with Lean Manufacturing or use the terms interchangeably, but they represent different approaches with distinct origins.

Six Sigma in manufacturing industry settings originated at Motorola in the 1980s, focusing primarily on reducing defects through statistical analysis.

The methodology aims to achieve 3.4 defects per million opportunities—a near-perfect standard that resonates with industries where precision is paramount.

Lean Manufacturing, conversely, evolved from Toyota’s Production System and concentrates on eliminating eight types of waste: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing.

Lean practitioners in manufacturing environments work to streamline processes, reduce inventory, and improve production flow.

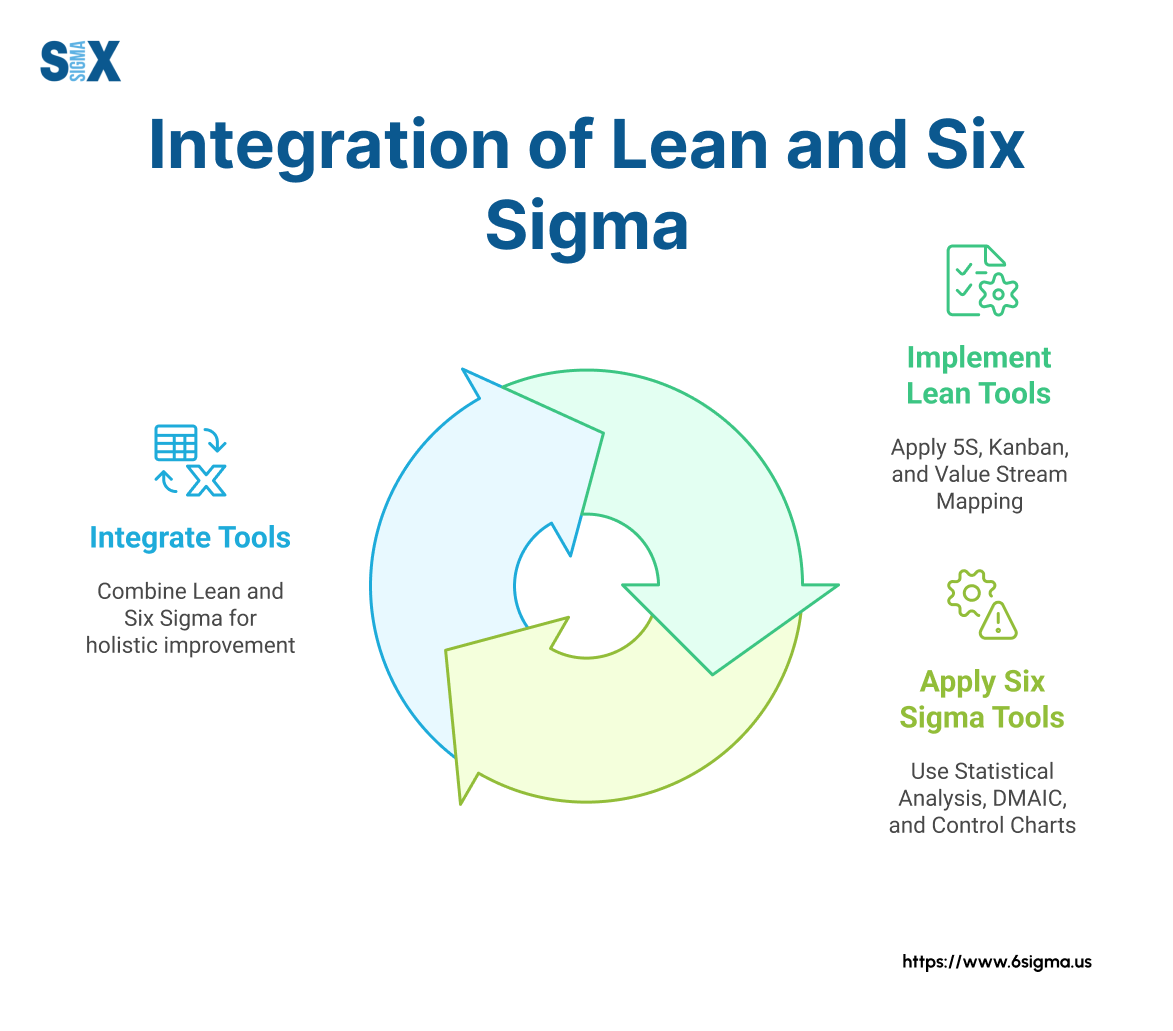

Integration of both methodologies

The integration of these methodologies creates a more balanced approach to manufacturing excellence.

While Lean helps identify and eliminate waste in production processes, Six Sigma provides the statistical tools to reduce variation and defects.

Together, they form a comprehensive system that manufacturing operations can use to drive continuous improvement.

This integration typically manifests in manufacturing through the DMAIC framework (Define, Measure, Analyze, Improve, Control) borrowed from Six Sigma, but with Lean tools incorporated throughout each phase.

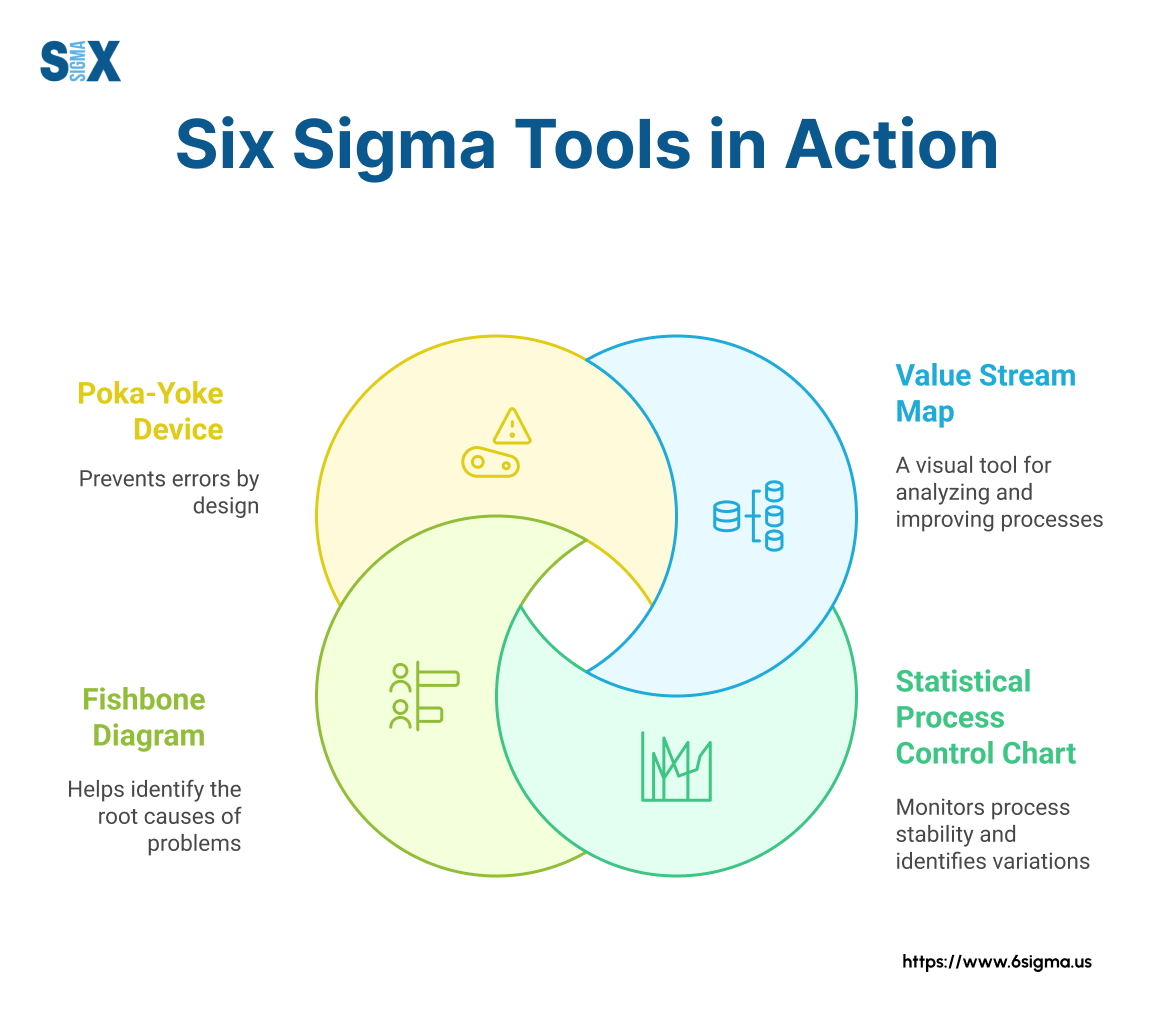

For example, during the Measure phase, teams might use Value Stream Mapping (a Lean tool) alongside Statistical Process Control (a Six Sigma technique) to gain deeper insights into production issues.

The DMAIC Framework

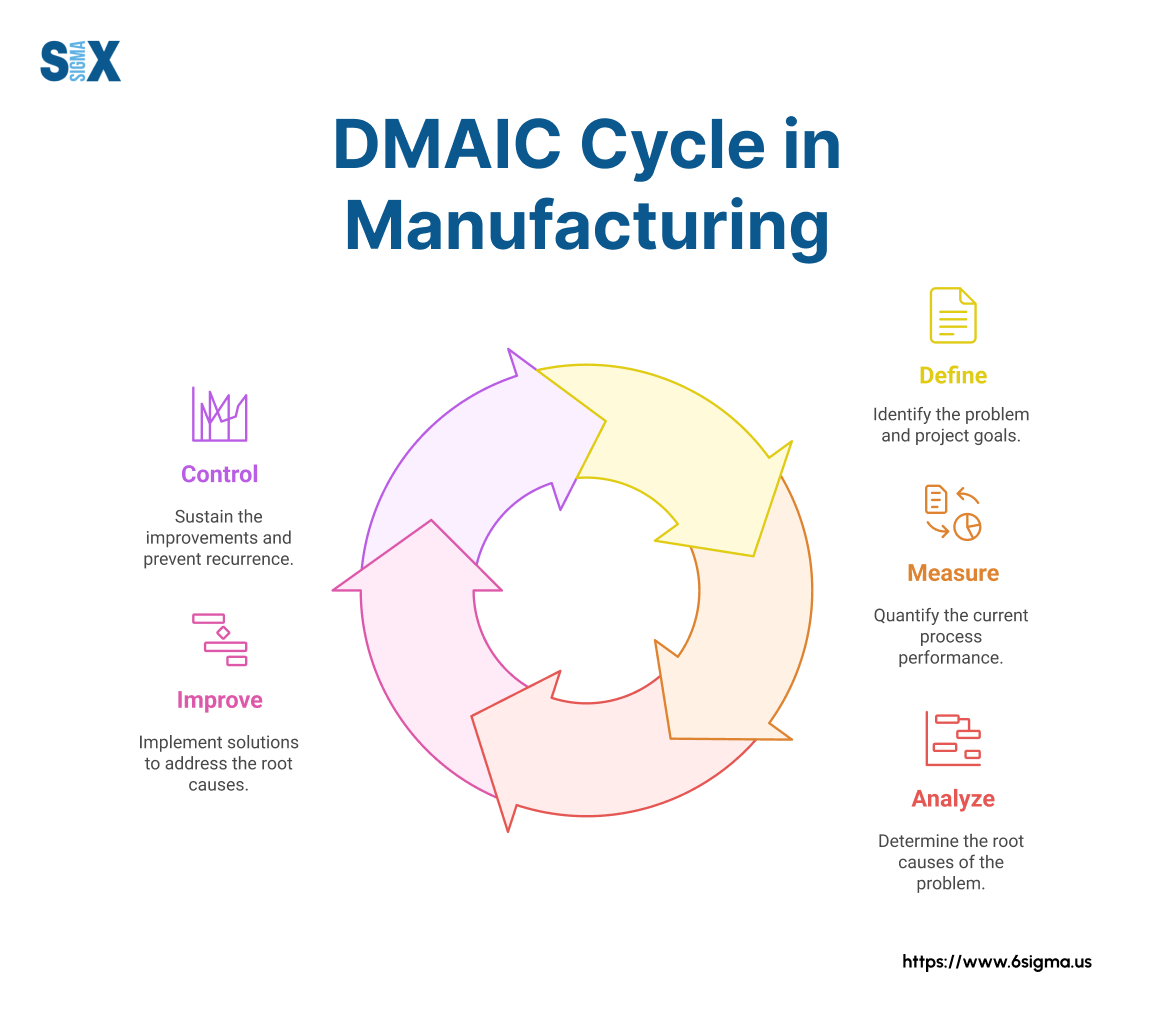

The backbone of Lean Six Sigma in manufacturing is the DMAIC framework—a structured, five-phase approach that guides teams through problem-solving and process improvement.

This methodical roadmap helps manufacturing teams tackle complex issues with clarity and precision, ensuring that improvements are data-driven and sustainable.

DMAIC stands for Define, Measure, Analyze, Improve, and Control. Each phase builds upon the previous one, creating a logical progression that prevents teams from jumping to solutions before fully understanding problems.

In the Define phase, manufacturing teams identify the problem, establish project scope, and clarify customer requirements. This initial step prevents scope creep and ensures alignment with business objectives.

Key tools used during this phase include Project Charters, SIPOC diagrams (Supplier, Input, Process, Output, Customer), and Voice of Customer analysis.

The Measure phase involves collecting baseline data about the current process. In manufacturing settings, this might include gathering defect rates, cycle times, or throughput metrics.

The goal is to establish a clear picture of current performance before making changes.Tools frequently used include data collection plans, process capability studies, and value stream mapping.

During the Analyze phase, teams dig deep into the data to identify root causes of problems.

This is where manufacturing professionals move beyond symptoms to understand the underlying issues affecting their processes.

Statistical analysis plays a crucial role here, helping teams distinguish between correlation and causation in complex manufacturing environments.

Common tools include Fishbone diagrams, Pareto analysis, and hypothesis testing.

A pharmaceutical manufacturing team might use root cause analysis techniques to determine why tablet coating thickness varies beyond acceptable limits, examining factors like raw material variations, equipment settings, and operator techniques.

The Improve phase is where solutions are developed and implemented. Based on the analysis of root causes, manufacturing teams design process changes, test them in controlled environments, and implement those that prove effective.

This phase requires creativity balanced with practicality—solutions must address root causes while being feasible within manufacturing constraints.

Tools used include design of experiments, mistake-proofing (poka-yoke), and pilot testing. An automotive parts manufacturer might implement automated inspection systems and revised work instructions after discovering that manual inspections were missing critical defects.

Finally, the Control phase ensures that improvements stick. Manufacturing teams develop monitoring systems, standardize new processes, and create response plans for when processes drift from targets.

This phase prevents the common problem of improvements fading over time as attention shifts elsewhere.

Control charts, standard operating procedures, and process audits are essential tools during this phase. For instance, an electronics manufacturer might implement daily control charting of soldering temperatures after improving a circuit board assembly process.

The power of DMAIC in manufacturing comes from its versatility. The same framework can address quality issues, reduce lead times, cut operational costs, or improve equipment reliability.

When applying DMAIC to lean six sigma in manufacturing, teams typically blend traditional Six Sigma statistical tools with Lean techniques.

Ready to Lead Improvement Projects?

Take your manufacturing career to the next level with advanced problem-solving skills.

Implementation in Manufacturing

Successful six sigma implementation in manufacturing industry settings doesn’t happen overnight.

It requires careful planning, appropriate resources, and a strategic approach tailored to your specific manufacturing environment.

Getting Started

Before launching a full-scale Lean Six Sigma initiative, several prerequisites must be in place to ensure the effort gains traction and delivers sustainable results.

Prerequisites for implementation

First, manufacturing organizations need to establish clear objectives aligned with business goals. Are you primarily focused on reducing defects, cutting lead times, improving on-time delivery, or reducing operational costs?

These objectives will guide your implementation strategy and help prioritize initial projects.

A thorough assessment of current processes provides the foundation for effective implementation. This baseline evaluation identifies performance gaps and potential areas for improvement.

Manufacturing plants often begin with a value stream mapping exercise to visualize material and information flow, highlighting bottlenecks and waste.

For those new to these concepts, a lean introduction can provide the fundamental knowledge needed to understand these assessment tools.

Leadership commitment represents perhaps the most critical prerequisite for Lean Six Sigma success in manufacturing. Without visible, active support from senior management, these initiatives often falter when they encounter resistance or compete for resources.

Leaders must not only approve the program but actively participate in reviews, remove barriers, and recognize achievements.

Role of leadership and culture

The role of leadership extends beyond mere approval to creating a culture that embraces continuous improvement.

In manufacturing environments, this means shifting from a blame-oriented approach to one that views problems as opportunities for improvement.

Culture change doesn’t happen through memos or mission statements. It requires consistent messaging, aligned incentives, and demonstrated commitment.

Manufacturing leaders should publicly participate in improvement activities, allocate time for staff to work on projects, and recognize both efforts and results.

Some companies designate specific times when production stops for improvement activities, signaling the importance of continuous improvement.

Time represents another crucial resource. Team members need dedicated time to work on projects, attend training, and implement solutions.

Manufacturing environments often struggle with this requirement due to production pressures, but without allocated time, improvement efforts stall.

Some companies address this by building improvement time into standard work schedules or temporarily backfilling positions.

Common Applications

The applications of six sigma in manufacturing span virtually every aspect of production operations, from raw material handling to finished goods delivery.

Understanding these common applications helps manufacturing teams identify where to focus their initial efforts for maximum impact.

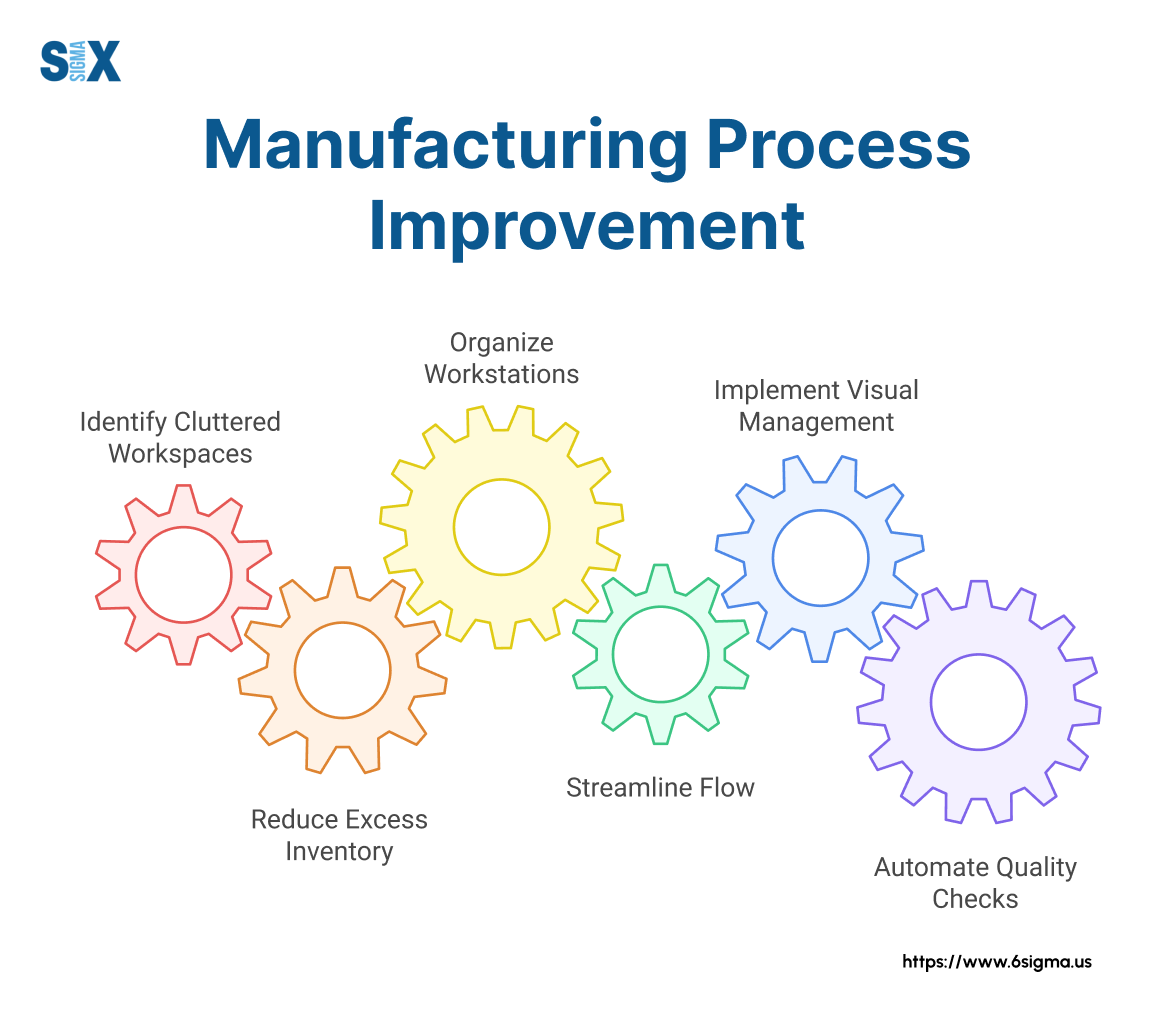

Process improvement examples

Process improvement examples abound in manufacturing settings. Assembly line balancing represents one frequent application, where Lean Six Sigma tools identify bottlenecks and redistribute work to create smoother flow.

A medical device manufacturer used this approach to increase throughput by 35% without adding equipment or staff, simply by rebalancing tasks and eliminating wasteful movement.

Setup time reduction offers another powerful application. Using SMED (Single-Minute Exchange of Dies) techniques from the Lean toolbox combined with Six Sigma’s statistical analysis, manufacturing teams can dramatically cut changeover times.

An automotive parts supplier reduced setup time from 45 minutes to 8 minutes on a critical stamping press, increasing available production time by over 100 hours annually.

Quality control applications

Quality control applications demonstrate some of the most dramatic six sigma examples in manufacturing. Statistical Process Control (SPC) helps production teams monitor processes in real-time, identifying shifts before they create defects.

A semiconductor manufacturer implemented SPC on wafer etching processes, reducing defect rates by 72% and saving millions in scrap and rework costs.

Root cause analysis techniques like the 5 Whys and Fishbone diagrams help quality teams identify and eliminate defect sources rather than just catching problems through inspection.

A furniture manufacturer struggling with inconsistent finish quality used these tools to trace problems to environmental conditions in their spray booth, implementing controls that reduced customer complaints by 83%.

Waste reduction strategies

Waste reduction strategies represent perhaps the most visible lean six sigma examples in manufacturing.

The 8 wastes framework (defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing) provides a lens for identifying improvement opportunities.

A food processing plant focused on reducing transportation waste by reorganizing their production floor, cutting material movement by 60% and improving throughput by 15%.

Inventory optimization balances customer service requirements with working capital efficiency. Using pull systems and kanban techniques, manufacturing operations can reduce excess inventory while maintaining service levels.

An electronics manufacturer implemented these approaches to reduce work-in-process inventory by 52%, freeing up cash and floor space while improving responsiveness.

These examples merely scratch the surface of how six sigma projects in manufacturing industry settings deliver tangible results. The methodology’s versatility allows it to address virtually any operational challenge, from quality and productivity to cost and delivery performance.

Tools and Techniques

The power of lean six sigma in manufacturing comes from its robust toolkit. These tools provide structured methods for analyzing processes, identifying problems, and implementing solutions.

While dozens of tools exist within the methodology, several stand out as particularly valuable for manufacturing environments.

Value Stream Mapping (VSM) serves as a cornerstone tool for visualizing entire processes from supplier to customer.

This powerful technique creates a detailed flowchart of material and information movement through your manufacturing operation, revealing bottlenecks, delays, and disconnects.

A properly executed VSM distinguishes between value-adding and non-value-adding activities, often revealing that less than 10% of total lead time actually adds value in typical manufacturing processes.

Manufacturing teams use VSM to document both current and future states. The current state map captures reality—warts and all—while the future state map represents the improved process after waste elimination. The gap between these states drives improvement activities.

Statistical Process Control (SPC) provides manufacturing teams with methods to monitor process performance in real-time.

This tool uses statistical techniques to distinguish between normal process variation and special causes requiring intervention. SPC implementation typically involves selecting critical quality characteristics, establishing measurement systems, determining appropriate control limits, and creating visual displays.

Control charts represent the most common SPC application in manufacturing. These charts plot process data over time with statistically calculated control limits.

Points falling outside these limits or displaying non-random patterns signal potential problems requiring investigation. A pharmaceutical manufacturer implementing SPC on tablet weight variation reduced out-of-specification products by 67% by detecting and addressing process shifts before they created defects.

The beauty of SPC in manufacturing environments lies in its preventive nature. Rather than inspecting quality into products after production, SPC monitors processes during production, allowing immediate correction before defects occur.

Root Cause Analysis (RCA) encompasses various techniques for identifying underlying causes of problems rather than just addressing symptoms.

Manufacturing operations frequently employ tools like 5 Whys, Fishbone Diagrams (Ishikawa), and Failure Mode and Effects Analysis (FMEA) to dig beneath surface issues.

The 5 Whys technique involves repeatedly asking why a problem occurs, typically five times, to drill down to root causes. This deceptively simple approach often reveals surprising insights.

A metal fabrication shop struggling with inconsistent weld quality used 5 Whys to trace the problem through operator technique and material handling issues to ultimately discover that loading dock scheduling created material storage problems affecting weld preparation.

Fishbone Diagrams provide a structured approach to brainstorming potential causes across six common categories: Man, Machine, Method, Material, Measurement, and Environment.

This visual tool helps manufacturing teams consider all possible factors contributing to a problem. An electronics manufacturer used a Fishbone Diagram to analyze circuit board testing failures, identifying 23 potential causes across all categories before narrowing focus to the three most significant factors.

Failure Mode and Effects Analysis (FMEA) takes a proactive approach by identifying potential failure modes before they occur.

Manufacturing teams rate potential failures based on severity, occurrence likelihood, and detection difficulty to calculate a Risk Priority Number (RPN). This prioritization helps focus improvement efforts on the highest-risk issues.

Other essential tools in the six sigma in manufacturing process toolkit include:

- Gage R&R (Repeatability and Reproducibility) studies ensure measurement systems provide reliable data.

- Process Capability Analysis compares process performance to customer specifications, quantifying how well a process meets requirements.

- Poka-Yoke (mistake-proofing) techniques prevent defects by making errors impossible or immediately obvious.

These tools represent just a subset of the six sigma examples in manufacturing applications. The methodology offers dozens of techniques for different situations and problems.

Master Advanced Six Sigma Tools

Lead organization-wide improvements with our comprehensive Six Sigma Black Belt Certification.

Training and Certification

Building internal capability stands as a critical success factor for lean six sigma in manufacturing environments.

Organizations that invest in training and certification create a sustainable improvement culture rather than relying on external consultants for every project. The structured belt system provides a clear development path for professionals at all levels of the organization.

The belt certification system originated in Six Sigma but has been adapted for Lean Six Sigma, creating a standardized framework for skill development.

Each belt level represents increasing proficiency and responsibility within improvement initiatives. Manufacturing organizations typically develop a mix of belt levels to support their improvement strategy.

White Belt certification serves as an entry point, providing basic awareness of Lean Six Sigma concepts and terminology. Six sigma white belt certification typically involves a short course (4-8 hours) covering fundamental principles, the DMAIC framework, and basic tools.

This level targets frontline manufacturing staff who need to participate in improvement activities without leading projects.

Yellow Belt certification builds on this foundation, providing deeper knowledge of improvement tools and limited project participation skills. Six sigma yellow belt certification typically requires 1-3 days of training and covers basic statistical tools, process mapping, and data collection methods.

Yellow Belts often support Green Belt projects while maintaining their regular manufacturing roles. A medical device manufacturer developed 60 Yellow Belts across production departments to create a network of improvement advocates who could identify opportunities and support larger initiatives.

Green Belt certification represents the first level capable of leading moderately complex improvement projects. Six sigma green belt certification typically involves 1-2 weeks of training plus completion of a significant improvement project.

Green Belts learn advanced statistical tools, project management techniques, and change leadership skills. They usually maintain their regular manufacturing roles while dedicating 25-50% of their time to improvement projects.

Black Belt certification designates full-time improvement professionals with advanced analytical skills and project leadership capabilities. Six sigma black belt certification typically requires 4 weeks of training plus completion of multiple high-impact projects.

Black Belts master complex statistical tools, change management techniques, and coaching skills. They typically lead multiple projects simultaneously while mentoring Green Belts.

Master Black Belt certification represents the highest level of technical expertise and program leadership. Six sigma master black belt certification requires extensive experience plus additional training in advanced methods and teaching techniques.

Master Black Belts develop training materials, coach Black Belts, and provide technical guidance on complex problems. They often oversee the entire Lean Six Sigma program for a manufacturing organization.

Training requirements vary by certification level but typically include classroom instruction, hands-on exercises, and project work.

Manufacturing-specific training incorporates relevant examples and tools particularly valuable in production environments.

Measuring Success

Quantifying the benefits of six sigma in manufacturing requires robust measurement systems.

Without clear metrics, organizations struggle to demonstrate value and maintain momentum for improvement initiatives. Effective measurement frameworks capture both process-level improvements and business-level impacts.

Critical metrics for lean six sigma in manufacturing typically span four categories: quality, delivery, cost, and safety. Within each category, organizations select specific indicators relevant to their operations and strategic priorities.

These metrics should balance leading indicators (predictive measures) with lagging indicators (outcome measures) to provide a complete picture of performance.

Quality metrics capture defect rates and process stability. Common measures include Defects Per Million Opportunities (DPMO), First Pass Yield (FPY), and Process Capability indices (Cp/Cpk).

A precision machining company tracked DPMO reduction from 15,000 to 2,200 across critical processes, demonstrating substantial quality improvement.

These metrics directly connect to customer satisfaction and warranty costs, making them powerful indicators of six sigma impact.

Delivery metrics focus on timeliness and responsiveness. Manufacturing organizations typically track On-Time Delivery (OTD), Manufacturing Lead Time, and Schedule Attainment.

Cost metrics capture efficiency and resource utilization. Common measures include Overall Equipment Effectiveness (OEE), Labor Productivity, and Manufacturing Cost per Unit.

Safety metrics track both incidents and near-misses. Manufacturing organizations monitor Lost Time Incident Rate (LTIR), Total Recordable Incident Rate (TRIR), and Safety Observation Completion.

Tracking methods have evolved significantly with technology advancements. Modern manufacturing operations increasingly implement digital dashboards providing real-time visibility into key metrics.

Avoided costs represent another significant benefit category. By improving existing processes, organizations often eliminate the need for capital expenditures.

Conclusion

Lean Six Sigma in manufacturing delivers powerful results when properly implemented. The methodology combines waste elimination with defect reduction to create more efficient, consistent production operations.

Organizations that successfully deploy these approaches gain competitive advantage through lower costs, better quality, faster delivery, and greater agility.

The journey begins with understanding the fundamental principles and tools of Lean Six Sigma.

The DMAIC framework provides a structured approach to problem-solving that prevents jumping to solutions before fully understanding problems.

Building internal capability through training and certification creates sustainable improvement rather than temporary gains.

The belt system provides a clear development path for manufacturing professionals at all levels, from frontline operators to senior leaders.

Organizations that invest in people development create a culture of continuous improvement that becomes self-reinforcing over time.

Selecting the right projects drives early momentum and organizational buy-in.

For organizations ready to begin or enhance their Lean Six Sigma journey, several next steps deserve consideration:

- Assess your current state to identify strengths, weaknesses, and high-impact opportunities.

- Develop a deployment strategy aligned with business priorities and organizational culture.

- Build internal capability through targeted training and certification programs.

- Select initial projects with high visibility and significant business impact.

- Establish measurement systems to track progress and demonstrate value.

Organizations seeking expert guidance on these steps often benefit from Lean six sigma consultation with experienced practitioners.

External perspective can accelerate deployment and help avoid common pitfalls, particularly during program launch.

The manufacturing landscape continues evolving with new technologies and competitive pressures. Lean Six Sigma provides a proven methodology for navigating this complexity and delivering sustained performance improvement.

Organizations that master these approaches position themselves for long-term success in an increasingly challenging global marketplace.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs