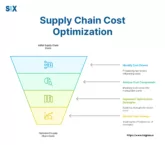

Supply Chain Cost Optimization: A Blueprint to Slash Costs with Lean Six Sigma

Uncontrolled supply chain expenses are not just a line item on a balance sheet; they are a critical business vulnerability. From fluctuating fuel prices and geopolitical disruptions to shifting consumer demands, the pressure on supply chain leaders has never been more intense. Simply reacting to these challenges is no longer enough. To survive and grow, […]