The Unspoken Truth About Six Sigma Failures: Guide to Prevention & Profitability

It’s a figure that should concern any executive: studies suggest that over 50% of Six Sigma projects fail to deliver their expected financial and operational returns.

These initiatives, launched with high hopes and significant investment, often end in frustration, wasted resources, and a team cynical about future improvements.

Concerned about the 50% failure rate?

Don’t let your projects become a statistic. Diagnose the hidden problems and build a strategy for profitable, successful initiatives from day one.

The common failure of six sigma isn’t due to the methodology itself, but in its application, leadership, and cultural integration. Understanding these pitfalls is the single most important step toward ensuring your projects succeed.

But what if you could flip the script? This guide is your strategic roadmap to move beyond just reading about problems and start implementing solutions.

Key Highlights

- What truly defines a Six Sigma failure.

- The core reasons most initiatives falter, from leadership to data.

- How to learn from real-world failure stories.

- A proactive plan to ensure your projects are successful and profitable from day one.

Defining Disaster: What Constitutes a Six Sigma Failure?

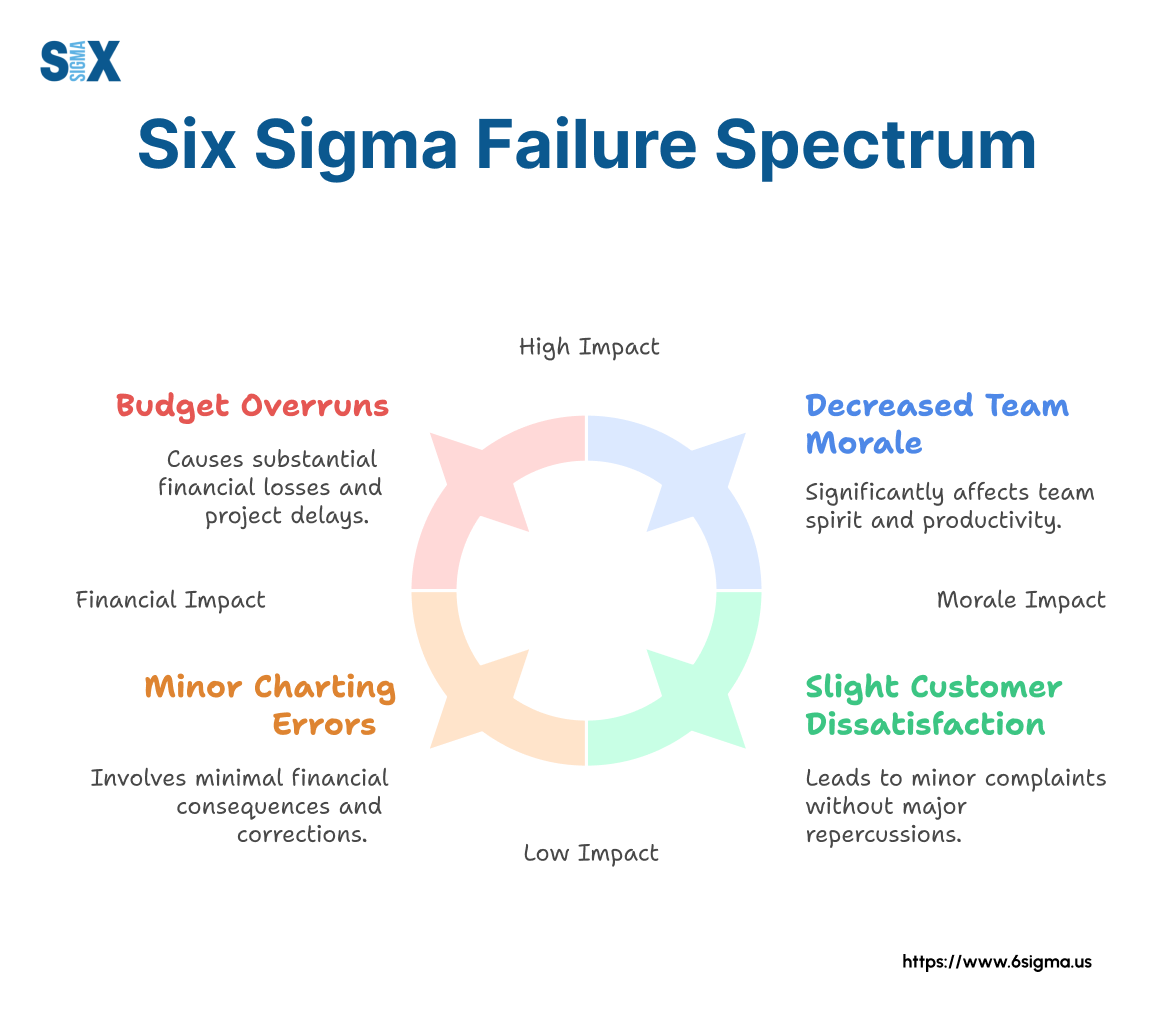

Before we can prevent failure, we must first define it. In the world of Six Sigma, failure isn’t always a dramatic, project-canceling event. It’s often a silent erosion of value.

While the theoretical 6 sigma failure rate of 3.4 defects per million opportunities (DPMO) is a benchmark for process quality, the failure rate of the projects themselves is a different and more complex issue.

A Six Sigma project can be considered a failure even if it’s “completed” but doesn’t meet its core objectives.

These critical failure factors can be broken down into two main categories:

- Hard Failures: These are the tangible, measurable shortfalls that directly impact the bottom line. This includes failing to achieve the projected financial ROI, not meeting the specific process improvement targets (e.g., cycle time reduction, defect reduction), or delivering a solution that is ultimately not implemented by the organization.

- Soft Failures: These are the intangible yet equally corrosive outcomes. This includes a decline in team morale, increased resistance to future change initiatives, creating a solution that alienates customers, or damaging the credibility of the continuous improvement program within the organization.

Understanding both types of failure is a core part of building a resilient program. It requires a baseline knowledge of the core principles of waste reduction and value creation, which are central to the fundamentals of Lean.

Ready to master the principles of waste reduction and value creation?

Lean Fundamentals provides the core knowledge you need to build a resilient improvement program.

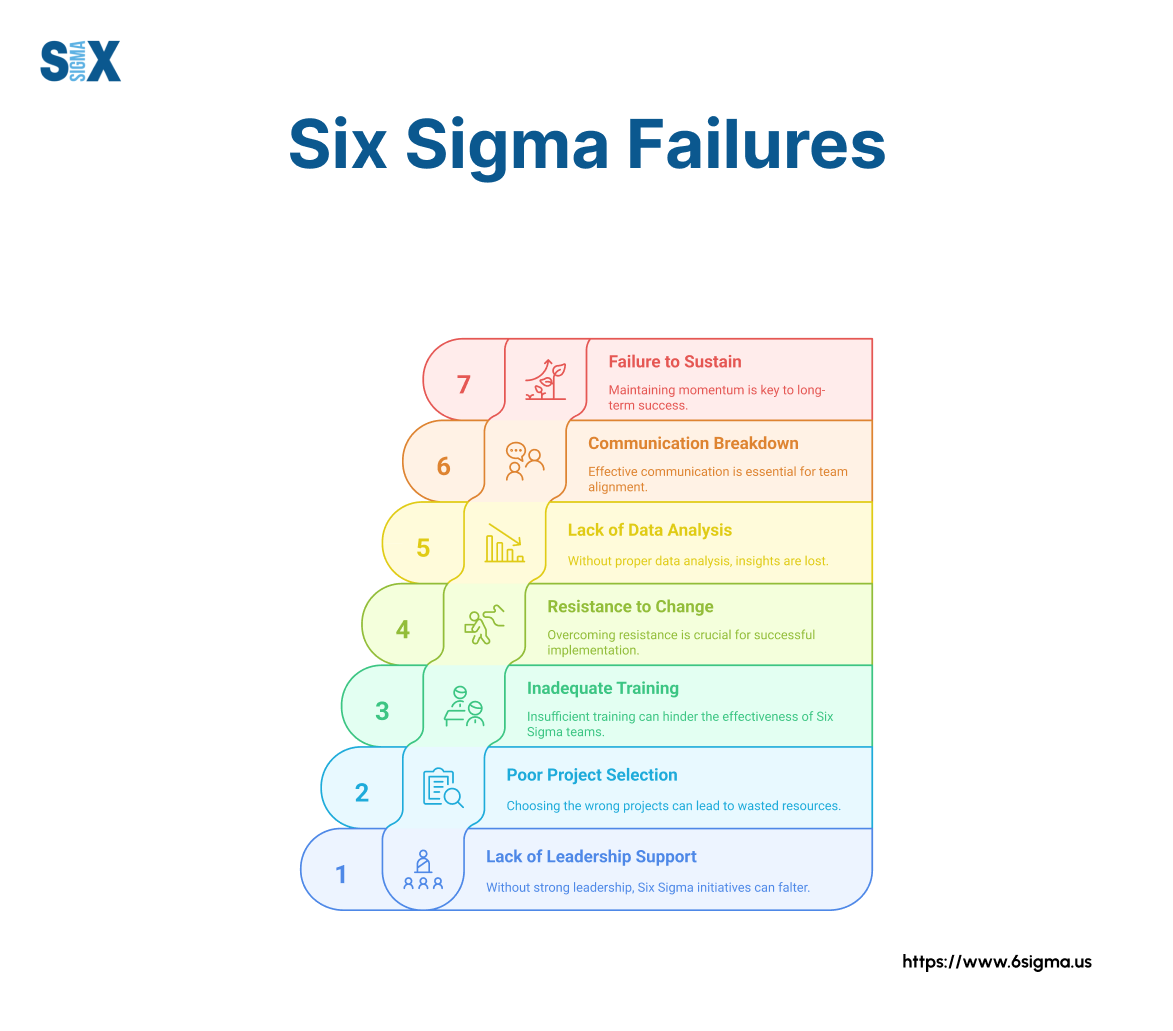

The Core Reasons: Why Most Six Sigma Initiatives Fail

While the symptoms of failure are varied, the root causes are remarkably consistent across industries. A Six Sigma initiative rarely fails because of a single, catastrophic event.

Instead, it succumbs to a series of underlying issues that were present from the start. Understanding these core reasons is the first step toward building a proactive defense for your projects.

The Leadership Void & Lack of Executive Buy-in

The single most cited reason for Six Sigma failure is a lack of genuine, active support from senior leadership.

When executives view Six Sigma as a “departmental thing” rather than a core business strategy, projects are immediately set up to fail.

This void creates a culture where the initiative is seen as optional, resources are difficult to secure, and inter-departmental barriers become impossible to overcome.

A classic six sigma failure story involves a mid-level manager tasked with a major supply chain optimization project.

While the project team was skilled and the data was solid, their C-suite sponsor was passive, rarely attending reviews and failing to champion the project’s needs at the executive level.

When the project required a significant change to another department’s workflow, it was met with a wall of resistance that the sponsor was unwilling to help break down.

The project quietly withered and was eventually abandoned, not because of a technical flaw, but because it lacked a powerful champion.

Effective leadership often requires the strategic oversight and authority provided by a six sigma master black belt certification, which equips leaders to bridge this exact gap between project teams and the C-suite.

Is a lack of executive sponsorship holding your initiatives back?

Equip your leaders with the strategic oversight to drive enterprise-level change with Six Sigma Master Black Belt.

A Culture of Resistance: When People Trump Process

You can have the most elegant process map and the most accurate data, but if your organization’s culture is resistant to change, your project will fail.

This cultural resistance is often subtle, manifesting as passive aggression, perpetual “analysis paralysis,” or the common refrain of, “This is how we’ve always done it.” A Six Sigma project isn’t just a technical implementation; it’s a change management initiative.

If the project team isn’t prepared to address the human element—the fears, the habits, and the politics—the new process will be rejected by the very people needed to make it work.

The Training Gap: Unskilled Teams and Misunderstood Roles

Another primary driver of lean six sigma failures is deploying teams that are inadequately trained for the task at hand.

Handing complex statistical tools to employees without proper instruction is a recipe for flawed data analysis, incorrect conclusions, and solutions that don’t solve the actual problem.

Success depends on a structured approach to capability building, where each team member has the right level of knowledge for their specific role.

Not everyone needs to be a statistical wizard, but a shared understanding is non-negotiable.

- Foundational knowledge for all employees involved, even peripherally, starts with a six sigma white belt certification, ensuring everyone speaks the same language.

- Team members who will be actively collecting data and participating in projects benefit immensely from the practical tools learned in a six sigma yellow belt certification.

- To effectively lead smaller-scale improvement projects and apply core tools like DMAIC, a six sigma green belt certification is the essential standard.

An unskilled team is a project’s biggest risk!

Ensuring every team member has the right level of training is non-negotiable. Compare Six Sigma Belts and build your expert team.

Poor Project Selection: The Failure Before You Begin

Many Six Sigma projects are doomed before they even start because they are the wrong projects. This happens when organizations choose initiatives that are:

- Too broad or complex: Trying to “boil the ocean” with a single project is a common mistake.

- Not linked to strategic goals: The project improves a process, but it’s a process that doesn’t significantly impact the company’s bottom line or strategic objectives.

- Lacking clear financial impact: Without a clear, quantifiable business case, projects struggle to maintain momentum and executive support.

Selecting the right projects is both an art and a science, requiring a keen understanding of the business’s most critical value streams.

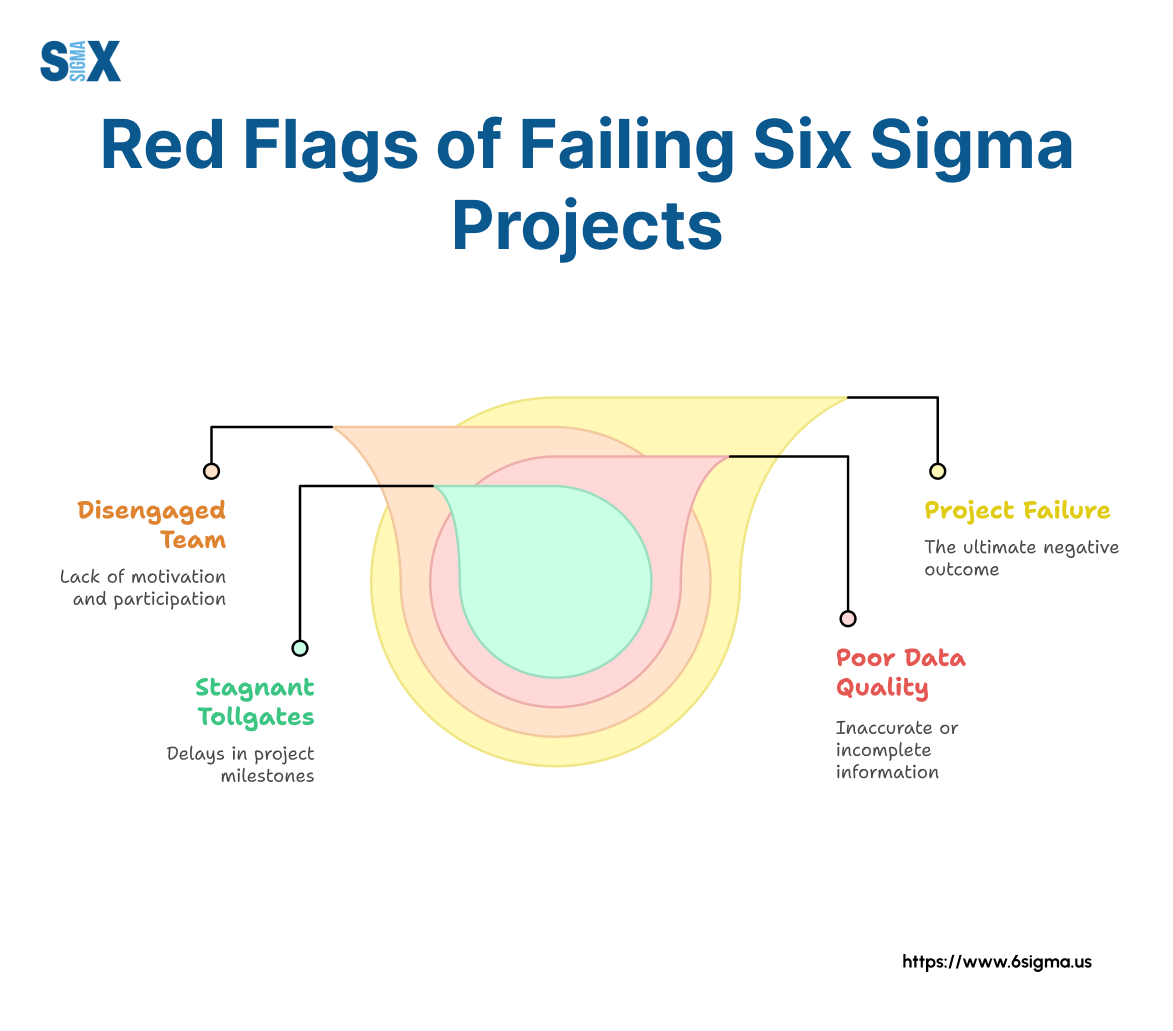

Early Warning Signs of Six Sigma Failures: How to Spot a Failing Project

A failing Six Sigma project rarely implodes overnight. It typically sends out distress signals long before it goes completely off the rails.

Recognizing these early warning signs provides an opportunity to intervene, reassess, and correct the course before the project becomes unsalvageable. Savvy leaders and project managers are constantly monitoring for these critical failure factors.

Here are some of the most common red flags that your Six Sigma project is at risk:

- Stagnant Project Tollgates: The project repeatedly fails to pass formal DMAIC tollgate reviews. This often indicates a fundamental problem with the data, analysis, or proposed solutions that isn’t being addressed.

- Poor Data Quality: The team expresses low confidence in the data they are collecting. They might struggle with the measurement system (Gage R&R failures) or find that the data is inconsistent, incomplete, or irrelevant.

- Declining Team Engagement: Attendance at team meetings drops. Key members are frequently “too busy” with their “real jobs” to contribute. This is a clear sign that the project has lost its perceived importance within the organization.

- Persistent Scope Creep: The project’s objectives and boundaries are constantly expanding. The team is trying to solve too many problems at once, diluting their focus and guaranteeing they won’t solve any of them well.

- Lack of Communication: Project updates become less frequent. Stakeholders are unclear on the project’s status, and there’s a general lack of transparency about progress and roadblocks.

These are precisely the issues a certified professional is trained to detect and rectify.

Learning from Giants: Real-World Lean Six Sigma Failures

Theory is one thing, but learning from the struggles of major corporations provides powerful, tangible lessons.

While many companies keep their internal struggles private, some six sigma failure stories have become well-known case studies in the business community, offering invaluable insights into the potential pitfalls of a poorly executed strategy.

These stories highlight how even the most powerful methodologies can backfire if they are not aligned with culture and customer experience.

One of the most frequently discussed examples of lean six sigma failures involves The Home Depot in the early 2000s under former CEO Robert Nardelli. The company rigorously implemented Six Sigma with a primary focus on cutting costs and standardizing operations.

While this approach did improve efficiency in some areas, it was widely criticized for damaging the company’s renowned customer-centric culture.

Experienced, knowledgeable staff were replaced with part-time workers to save money, and the rigid focus on process efficiency alienated customers who relied on expert advice.

The lesson learned was profound: applying Six Sigma purely as a cost-cutting tool without considering its impact on customer value and employee morale can lead to disastrous results for a brand.

Dissecting these cautionary tales requires a structured approach. It’s not enough to simply read the story; one must analyze the chain of events to find the true source of the problem.

The best method for this is to conduct a thorough analysis of the underlying causes, a core tenet of effective six sigma failures analysis (more commonly known as Root Cause Analysis).

By systematically breaking down where things went wrong, organizations can extract valuable lessons to apply to their own initiatives.

The Proactive Blueprint: From Reactive Fixes to Active Prevention

Understanding why projects fail is critical, but it’s only half the battle. The ultimate goal is to build a system that prevents these failures from ever taking root.

A proactive approach moves your organization from a reactive state of fixing broken projects to an active state of building successful ones from the ground up.

This blueprint is built on three pillars: deeply understanding past mistakes, anticipating future risks, and building a team capable of navigating any challenge.

Mastering Root Cause Analysis to Understand the “Why”

You cannot prevent a problem you don’t fully understand. True prevention begins with a commitment to dissecting past mistakes, no matter how small.

When a project hits a roadblock or fails to deliver, the immediate response should not be to assign blame, but to launch a structured inquiry.

Simple but powerful techniques like the “5 Whys” or a more detailed Fishbone (Ishikawa) Diagram allow teams to peel back the layers of a problem and move beyond the surface-level symptoms to find the true origin.

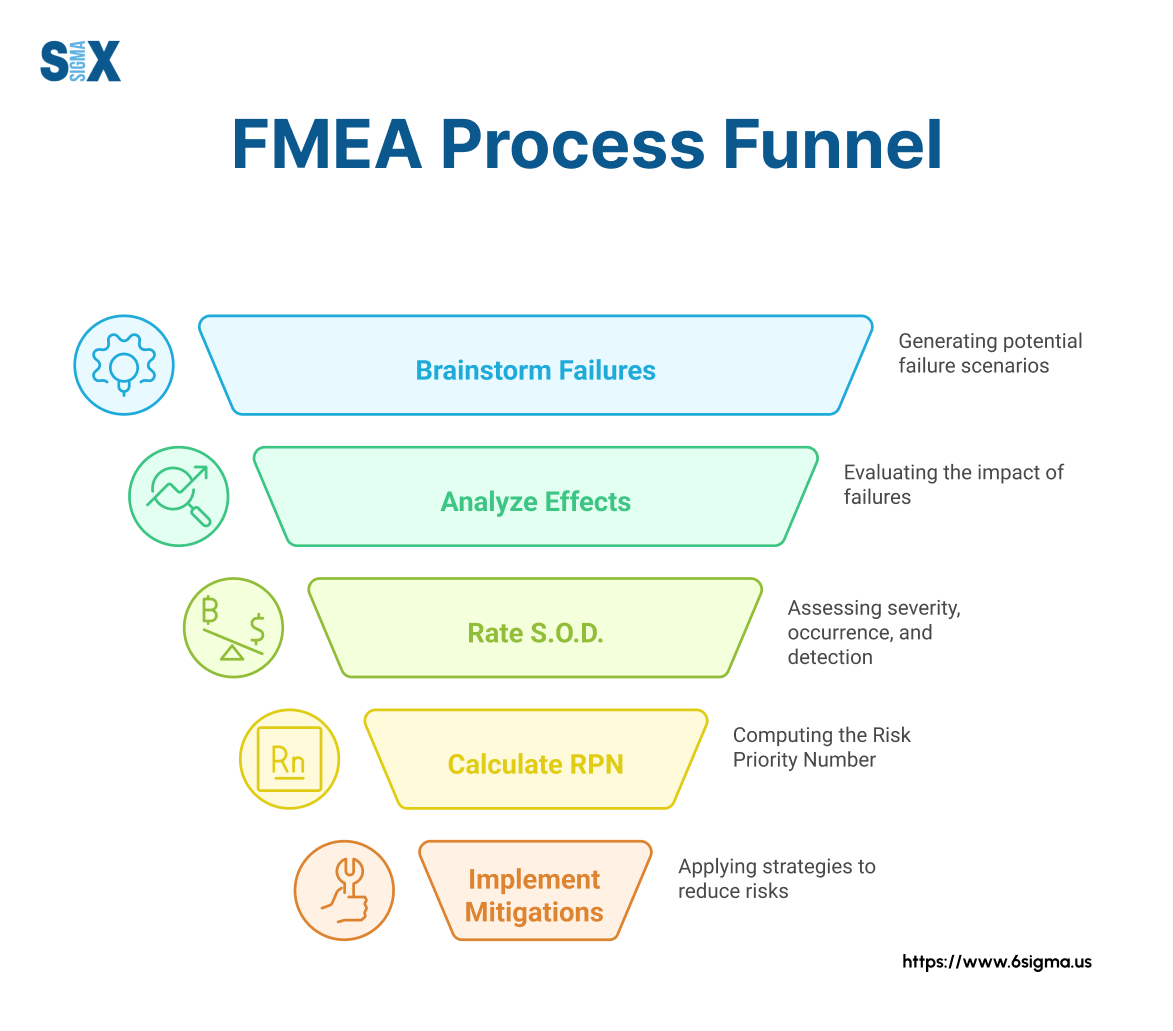

A Primer on Six Sigma Failure Mode Effects Analysis (FMEA)

While Root Cause Analysis is reactive, Six Sigma Failure Mode Effects Analysis (FMEA) is its powerful, proactive counterpart.

This is the ultimate tool for risk mitigation. An FMEA is a systematic process used to identify and prevent potential failures before they can ever occur.

The process involves:

- Mapping out a process or product design.

- Brainstorming all potential “failure modes” (what could go wrong?).

- Analyzing the potential “effects” (the consequences of each failure).

- Identifying the potential causes of each failure.

- Scoring each potential failure on its Severity, Occurrence, and Detectability to calculate a Risk Priority Number (RPN).

This process allows teams to focus their preventative efforts on the highest-risk areas, designing controls and countermeasures to ensure the most critical failures never happen.

Performing a detailed FMEA is a key competency developed during six sigma green belt certification training, empowering teams to build quality and resilience directly into their processes.

Building a Success-Oriented Team from the Ground Up

Ultimately, the best defense against failure is a well-structured, highly-skilled, and properly supported team.

A culture of continuous improvement is not built on tools and charts, but on people who are confident and capable of driving change.

This requires a clear hierarchy of skills and responsibilities, where every individual understands their role in the larger mission.

A successful program structure looks like this:

- The strategic vision is set and championed by senior leaders, whose effectiveness is amplified when they hold a six sigma master black belt certification.

- Complex, high-impact, cross-functional projects are managed by those with the advanced analytical and leadership skills from a six sigma black belt certification.

- And the foundation of project execution is built upon dedicated team members who possess the practical, hands-on knowledge of a six sigma yellow belt certification, supporting the project with data collection and process mapping.

Turning Six Sigma Failures into Your Greatest Competitive Advantage

The journey through the landscape of Six Sigma failures reveals a consistent and powerful truth: projects don’t fail because the methodology is flawed; they fail when the human and strategic elements are ignored.

The most common pitfalls—a void in leadership, a culture resistant to change, inadequately trained teams, and poor project selection—are not technical problems but organizational ones.

By understanding these root causes, you can transform them from potential liabilities into your greatest strategic advantage. Recognizing the early warning signs allows for timely intervention, while proactively using tools like FMEA builds a foundation of resilience.

The difference between a company that succeeds with Six Sigma and one that adds to the failure statistics lies in this commitment to building a culture of prevention, backed by a well-trained and fully supported team.

Don’t let your organization become another cautionary tale. Now is the time to take action and build a program that delivers on its promise of transformational results.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs