Reduce Manufacturing Defects: A Step-by-Step Six Sigma Guide

The hidden costs of poor quality can consume 15-20% of a company’s total sales revenue. For a $10 million business, that’s up to $2 million annually lost to scrap, rework, warranty claims, and customer returns.

But the true cost is even higher.

It’s the damage to your brand’s reputation, the erosion of customer trust, and the frustration of a team constantly fighting fires instead of driving innovation.

Turn Quality into Profit

See how a strategic approach to defect reduction can do more than just save money—it can become a powerful engine for growth and profitability for your entire organization.

If you’re tired of battling the same recurring production issues, you’re not just looking for a quick fix; you’re looking for a systematic, permanent solution.

This isn’t about working harder; it’s about working smarter.

The Hidden Costs of Defects: Why “Good Enough” Is a Failing Strategy

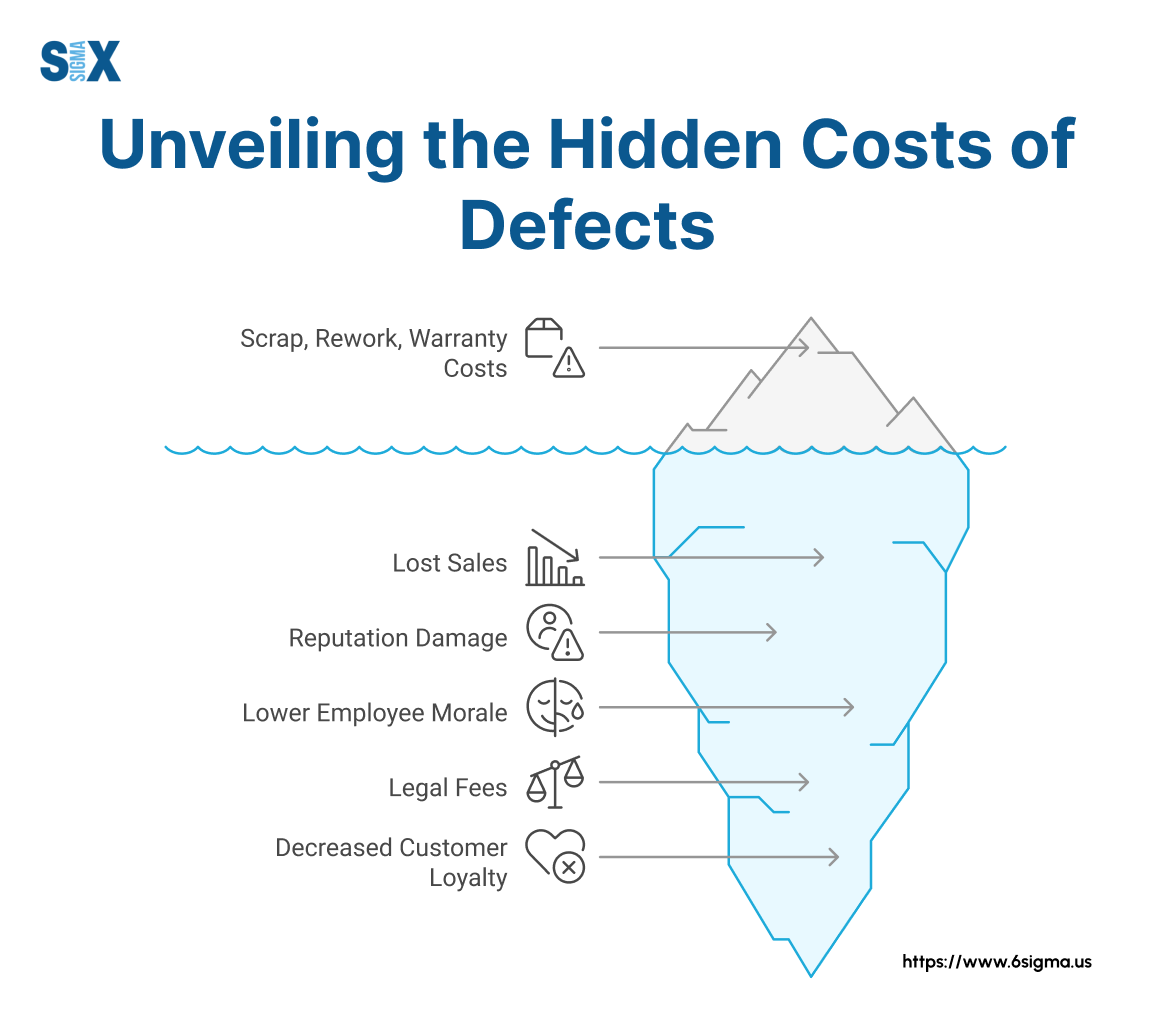

The most visible costs of a manufacturing defect—the scrap materials, the rework hours, the shipping fees for returns—are often just the tip of the iceberg.

While they directly impact your bottom line, the truly damaging costs are the ones lurking beneath the surface.

These are the hidden expenses that slowly erode your company’s foundation and competitiveness.

Think about the ripple effect of a single defect that reaches a customer.

It triggers a customer service call, consumes employee time in processing the return, and potentially leads to a negative online review that dissuades countless future buyers.

This is where the real damage lies:

- Reputational Damage: In today’s hyper-connected world, news of poor quality spreads fast. A single viral post or a series of bad reviews can permanently tarnish a brand’s image as unreliable.

- Lost Customer Trust: When a product fails, customers don’t just lose faith in that one item; they lose faith in your company. That trust is incredibly difficult and expensive to win back.

- Lowered Employee Morale: A workplace focused on constant rework and fixing mistakes is a frustrating environment. It stifles innovation and leads to burnout, affecting overall productivity and employee retention.

- Legal and Regulatory Liability: The critical question every manager must consider is, “Who is liable for a manufacturing defect?” The answer is unequivocally the company. A significant defect can lead to costly product recalls, regulatory fines, and even consumer lawsuits, turning a production issue into a multi-million dollar legal crisis.

The automotive industry, for example, has seen numerous recalls where the cost of replacing a single faulty component snowballed into billions of dollars in losses and irreparable brand damage.

Viewing defects as merely a line item for scrap is a failing strategy. To truly understand their impact, you must see them as a direct threat to your brand’s reputation, your customer relationships, and your company’s long-term financial health.

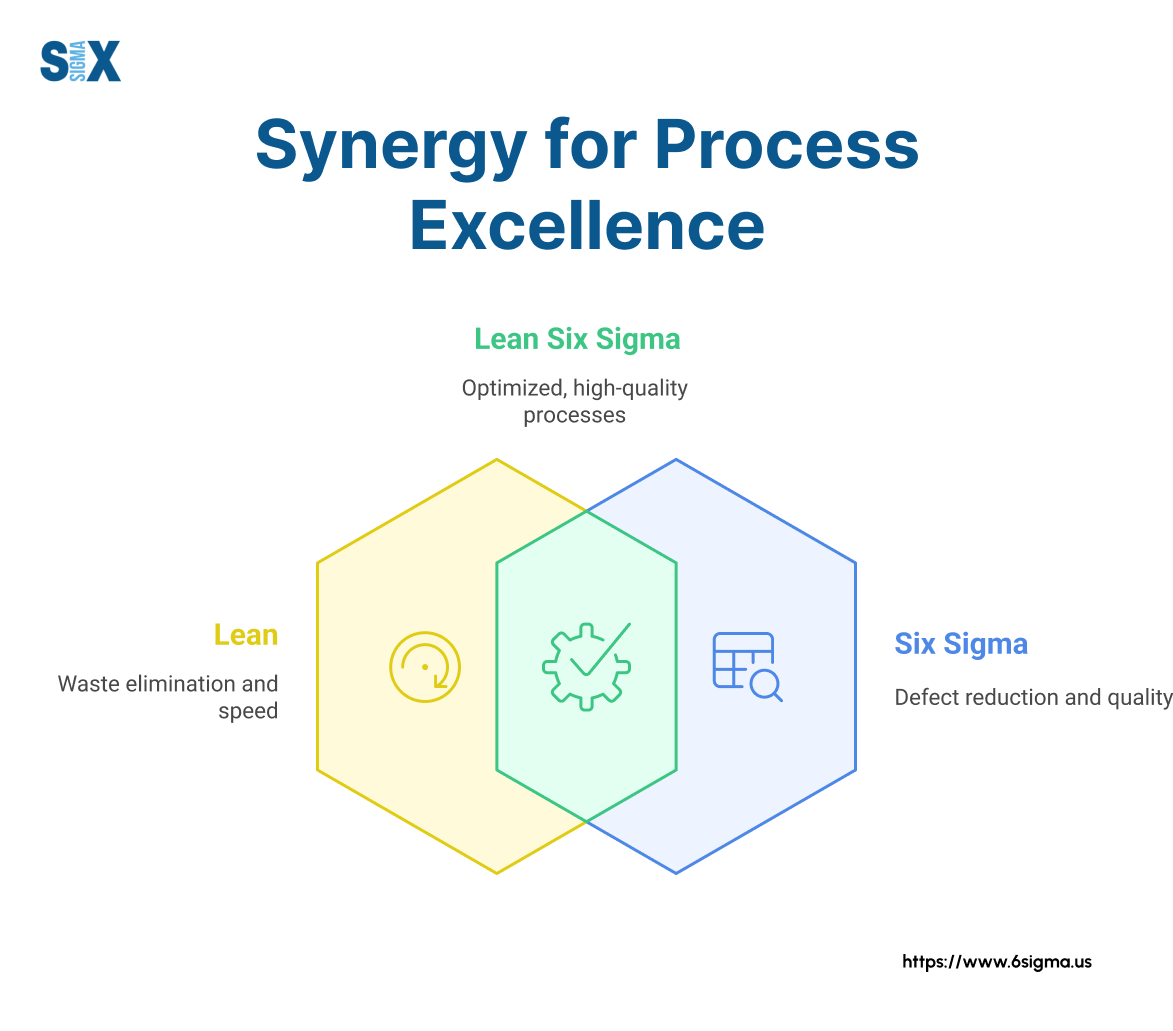

Your Introduction to the Lean Six Sigma Method

To conquer the costly and complex problem of manufacturing defects, you need more than just good intentions—you need a proven system.

This is where Lean Six Sigma emerges as the gold standard for operational excellence.

It’s not just a collection of tools, but a holistic business methodology that fundamentally changes how you view and manage your production processes. It combines two powerful disciplines into one cohesive framework.

First, Lean is relentlessly focused on maximizing value by eliminating waste. Originally pioneered by Toyota, it identifies non-value-adding activities—like excess inventory, unnecessary motion, and waiting times—and systematically removes them to improve flow and increase speed.

Second, Six Sigma is a data-driven approach laser-focused on eliminating defects by reducing process variation. If Lean makes you fast, Six Sigma makes you good. It operates on the principle that variation is the enemy of quality.

By using statistical analysis to understand and control fluctuations in your process, you can make defect rates so low they are almost negligible—the ultimate goal being just 3.4 defects per million opportunities.

When you merge these two disciplines, you create a powerful engine for manufacturing process optimization.

You get a system that is not only lean and efficient but also incredibly consistent and reliable.

This represents a fundamental shift in thinking. Instead of relying on end-of-the-line inspections to catch errors after they’ve already occurred (and cost you money), Lean Six Sigma is a way of preventing mistakes and defects in manufactured products from the very beginning.

It’s about building quality into every single step. Before you can build, however, you must understand the bedrock of efficiency, which is why a firm grasp of the fundamentals of Lean is so critical to this entire process.

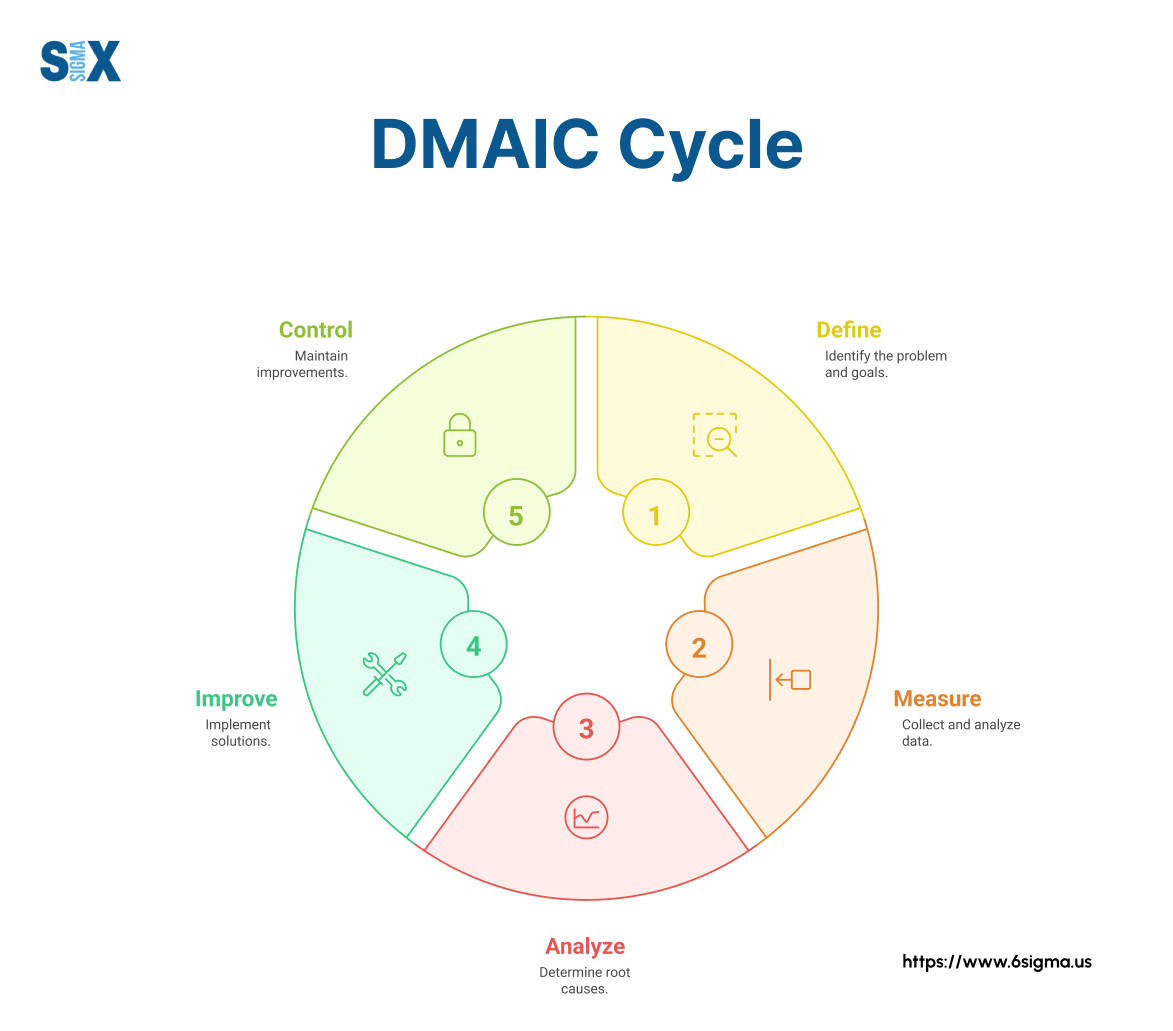

The DMAIC Method: Your 5-Step Roadmap to Reducing Manufacturing Defects

At the heart of every successful Six Sigma project is the DMAIC framework. This acronym stands for Define, Measure, Analyze, Improve, and Control. It is a disciplined, five-phase methodology that provides a scientific and data-driven roadmap to solve complex problems.

Instead of relying on guesswork or intuition, DMAIC forces teams to ground their decisions in hard evidence, ensuring that solutions are not just effective but also sustainable. Think of it as the core operating system for your quality improvement initiatives.

By following this structured path, you can systematically dissect any manufacturing challenge, identify its true source, and implement lasting changes that dramatically decrease the defect rate in production.

Step 1: Define – Pinpointing the Problem and Setting Clear Goals

The absolute first step in correcting a manufacturing defect is to Define the problem with crystal clarity. This phase sets the foundation for the entire project and ensures that everyone is aligned and working toward the same objective.

A poorly defined problem almost always leads to a failed solution.

Key activities in this stage include creating a project charter, which is a formal document that outlines the issue, the project goals (e.g., “reduce cosmetic paint blemishes on Model X by 50% within three months”), the scope, the timeline, and the team members involved.

It also involves clearly identifying the customer—whether internal or external—and understanding their specific requirements through a process known as capturing the Voice of the Customer (VOC). This ensures your efforts are focused on what truly matters.

Step 2: Measure – Quantifying the Current State of Your Process

Once the problem is defined, you must Measure its true scope. This phase is about moving from anecdotal evidence (“we get a lot of returns”) to objective, quantifiable facts.

The goal is to establish a reliable baseline of current performance. Teams map out the existing process to identify all the steps, then develop a data collection plan to gather information on key metrics.

This often involves using a defect tracking system or check sheets to log the frequency and types of defects occurring. The data collected here is used to calculate the current process capability, often expressed as a sigma level or in Defects Per Million Opportunities (DPMO).

This baseline is critical; without it, you have no way of knowing if your future improvements have actually made a difference.

Step 3: Analyze – Uncovering the True Root Cause of Defects

With solid data in hand, the team moves into the Analyze phase—the detective work. This is where you dig deep to uncover the root cause, or causes, of the problem.

Simply addressing the symptoms (like a scratch on a product) is a temporary fix; analyzing the data allows you to find the source (like a misaligned guide rail on a conveyor).

This phase utilizes a variety of powerful analytical techniques for defect reduction in industry, including Fishbone (Ishikawa) diagrams to brainstorm potential causes, the 5 Whys to drill down to the source of an issue, and Pareto charts to identify the “vital few” causes that are responsible for the majority of defects.

The core of this phase is effective problem-solving. Mastering these methods for reducing manufacturing defects is key to making lasting improvements.

Step 4: Improve – Implementing and Testing Effective Solutions

Analysis reveals the cause; the Improve phase delivers the solution. Here, the team brainstorms potential solutions that directly address the root causes identified in the previous step.

The most promising ideas are then selected and often tested on a small scale through a pilot program.

This allows the team to validate the effectiveness of the solution and work out any kinks before a full-scale rollout, minimizing disruption and risk.

This phase is about creativity backed by data, ensuring that the chosen improvements are the most effective and efficient options.

Executing these improvement projects often falls to team members who have earned their Six Sigma Yellow Belt certification, as they are trained in the fundamental tools of process improvement and can help facilitate the implementation of these positive changes on the factory floor.

Step 5: Control – Sustaining the Gains and Preventing Future Defects

An improvement that doesn’t last is a wasted effort. The final and most critical phase, Control, is designed to sustain the gains and ensure the problem does not reappear over time.

This involves creating a control plan and updating standard operating procedures (SOPs) to make the improved process the new standard.

Teams often implement Statistical Process Control (SPC) charts to monitor the process in real-time, providing an early warning if performance starts to drift.

This phase is about locking in the success of the project and establishing mechanisms to maintain the new, higher level of performance.

It ensures the hard work from the previous four phases delivers long-term value to the organization, completing the cycle of continuous improvement.

Ready to Lead an Improvement Project?

The DMAIC framework is a powerful roadmap, and Lean Six Sigma Green Belt Certification is the one who holds the map.

Building a “Zero-Defect” Culture: The People Behind the Process

Implementing the DMAIC method and using advanced tools will undoubtedly lead to improvements, but these gains can be short-lived without the right culture to support them.

A true “zero-defect” environment is not just the result of better machinery or software; it’s the product of a workforce that is empowered, engaged, and aligned around the principles of quality.

Building this culture means investing in your people, providing them with the skills and knowledge to become active participants in the continuous improvement journey.

This creates a sustainable system for production yield improvement that is driven by everyone, from the front lines to the executive suite.

In a Lean Six Sigma organization, quality is not the sole responsibility of a single department. It is a shared mindset, and different roles require different levels of expertise to contribute effectively.

This is where a structured training and certification path becomes invaluable, creating a common language and a clear hierarchy of skills.

- Foundational Awareness (White Belt): The journey begins by empowering your entire team with a foundational understanding of the goals. Team members with a Six Sigma White Belt certification learn the basic vocabulary of Lean Six Sigma, enabling them to understand their role within the larger quality framework and contribute to improvement conversations.

- Active Contribution (Yellow Belt): For team members who will be active participants in improvement projects, a deeper level of knowledge is required. Those who pursue a Six Sigma Yellow Belt certification are trained in the fundamental tools, allowing them to assist with process mapping, data collection, and the implementation of solutions.

- Project Leadership (Green Belt): Every successful improvement initiative needs a capable leader. To lead effective DMAIC projects that solve significant departmental issues, professionals typically need a Six Sigma Green Belt certification. This equips them with the statistical tools and project management skills to guide a team from problem definition to a controlled solution.

- Expert Problem-Solving (Black Belt): When faced with complex, chronic problems that span multiple departments and have a major financial impact, you need an expert. A leader with a Six Sigma Black Belt certification is a full-time agent of change, capable of managing high-stakes projects and deploying advanced statistical analysis.

- Strategic Oversight (Master Black Belt): At the highest level, quality becomes a core business strategy. The role of the Six Sigma Master Black Belt certification holder is to guide this strategy, mentor Black Belts and Green Belts, and ensure that all improvement projects are aligned with top-level business goals.

By investing in this tiered structure of expertise, you create a self-sustaining ecosystem of quality improvement that is embedded in the very fabric of your organization.

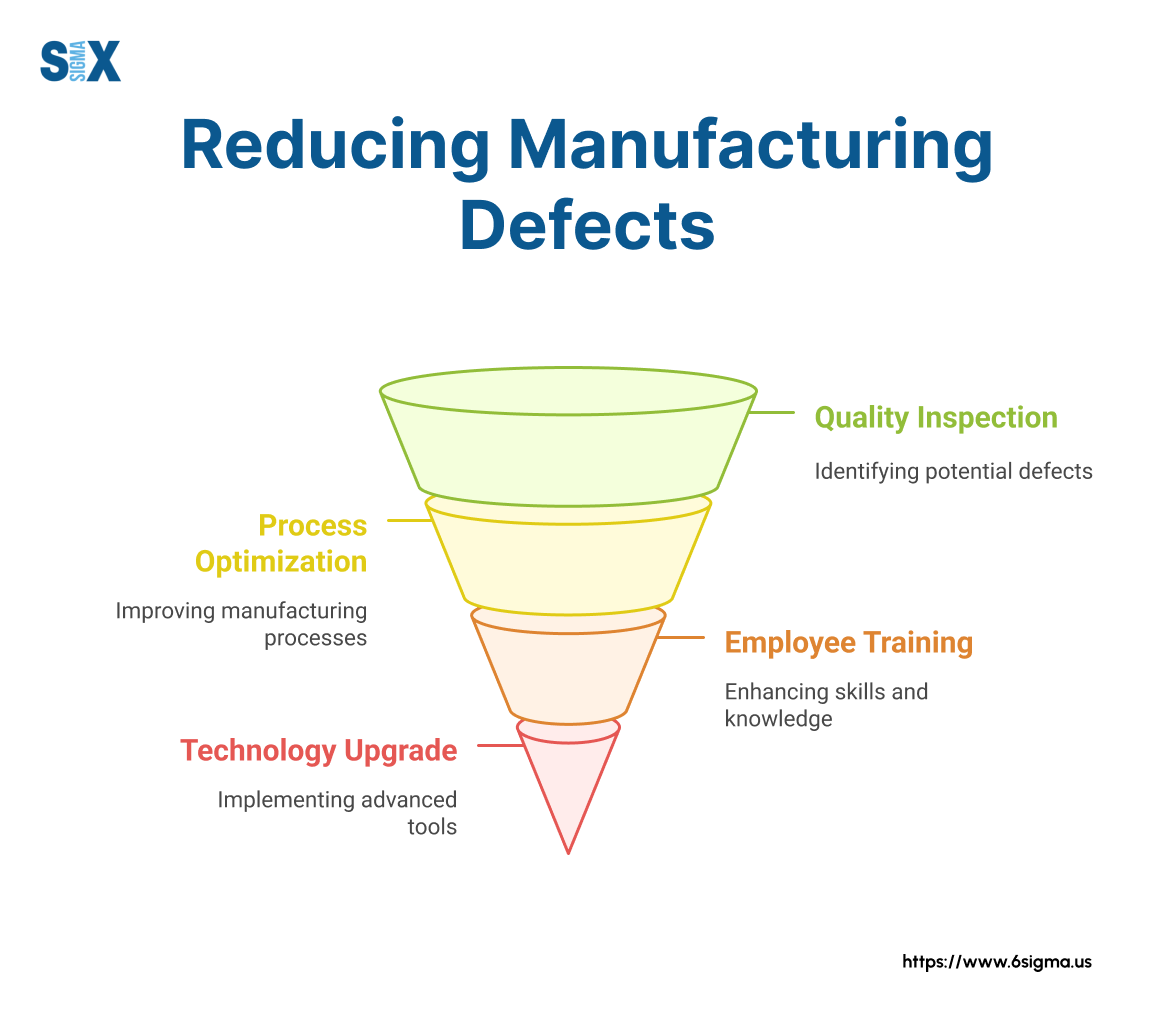

Essential Tools and Techniques for Reduce Manufacturing Defects

While the DMAIC framework provides the strategic roadmap, a skilled team needs a toolbox of practical techniques to execute the plan.

These tools to reduce defects in manufacturing are applied during the various phases of an improvement project to analyze processes, identify waste, and implement foolproof solutions.

They are the proven, hands-on methods for reducing manufacturing defects that bring the principles of Lean Six Sigma to life on the factory floor.

Here are some of the most powerful techniques in your arsenal:

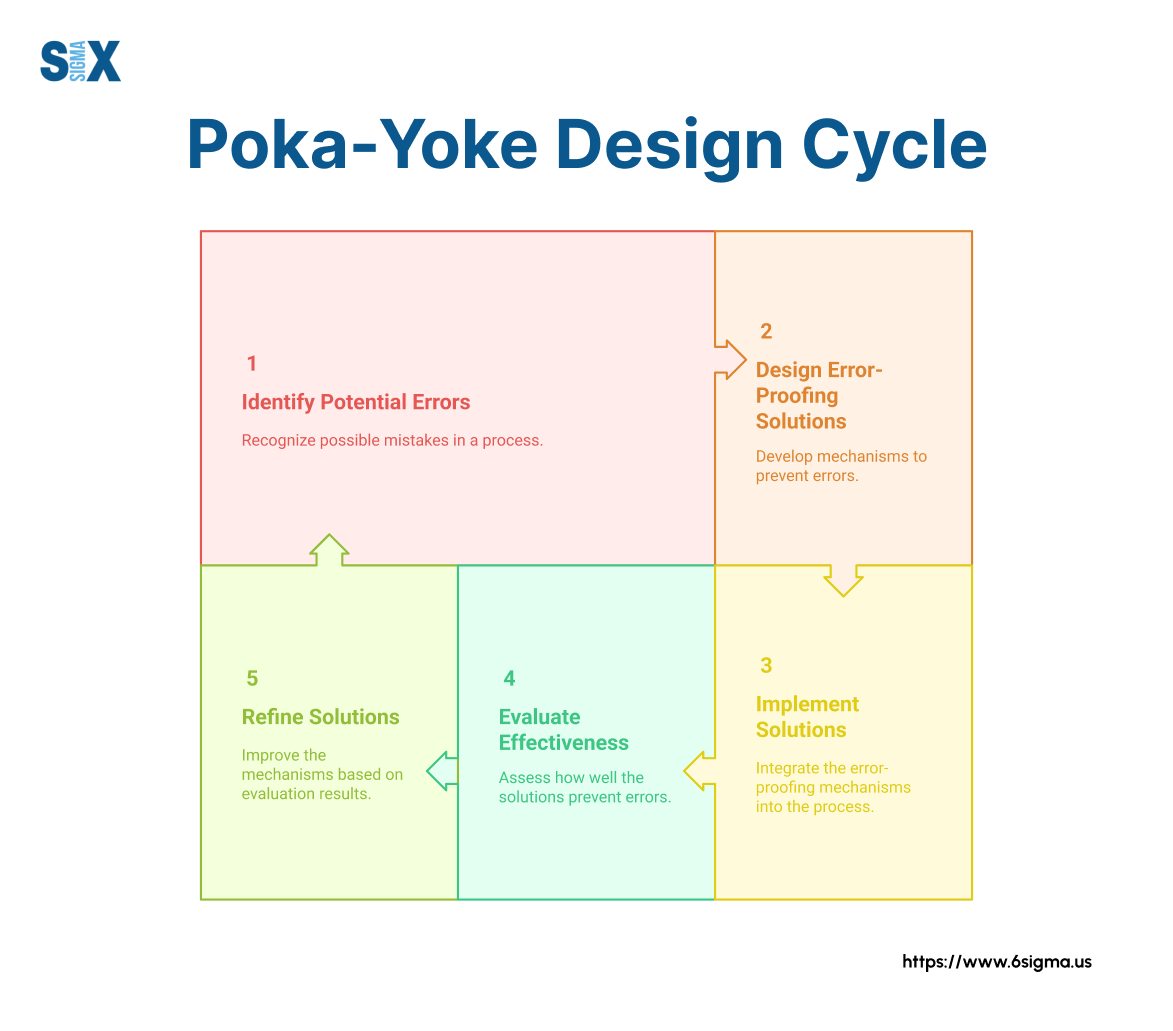

- Poka-Yoke (Mistake-Proofing)

This is a Japanese term that translates to “mistake-proofing.” A Poka-Yoke is any mechanism in a manufacturing process that helps an operator avoid (yokeru) mistakes (poka). Its purpose is to eliminate defects by preventing, correcting, or drawing attention to human errors as they occur.- Practical Example: A fixture for an assembly process is designed so that a part can only be inserted in the correct orientation. It is physically impossible to assemble it incorrectly.

- Practical Example: A fixture for an assembly process is designed so that a part can only be inserted in the correct orientation. It is physically impossible to assemble it incorrectly.

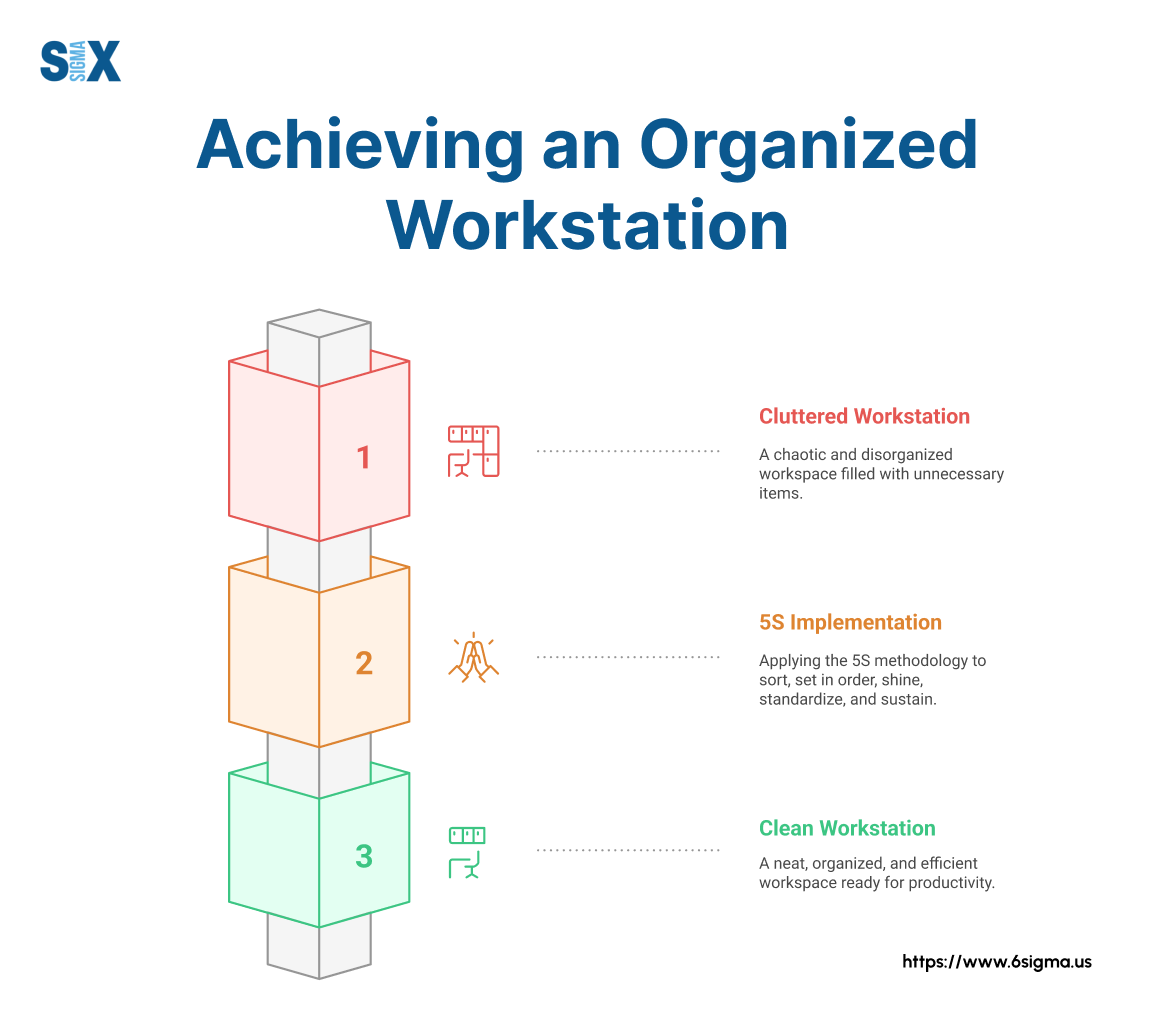

- 5S Methodology

The 5S methodology is a system for creating a workplace that is clean, organized, and efficient. This isn’t just about housekeeping; it’s about creating a visual workplace where abnormalities (like a missing tool or a fluid leak) are immediately obvious. The five steps are: Sort, Set in Order, Shine, Standardize, and Sustain.- Practical Example: A mechanic’s workstation where every tool has a designated spot on a shadow board, making it fast to find and easy to notice if something is missing.

- Practical Example: A mechanic’s workstation where every tool has a designated spot on a shadow board, making it fast to find and easy to notice if something is missing.

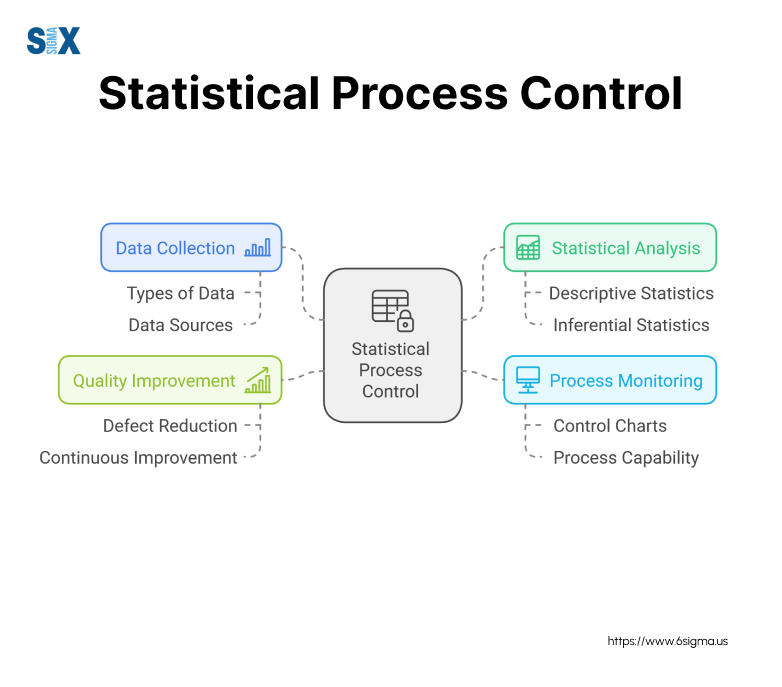

- Statistical Process Control (SPC)

SPC involves using statistical charts to monitor and control a process in real time. By plotting data points over time, control charts help you distinguish between “common cause” variation (the normal noise in a process) and “special cause” variation (an unexpected problem that needs investigation).- Practical Example: To understand how to reduce casting defects in manufacturing, a foundry could use an SPC chart to monitor the temperature of molten metal. If the temperature goes outside the statistically determined control limits, it signals an issue that could lead to defects before a bad part is even made.

- Value Stream Mapping (VSM)

A Value Stream Map is a comprehensive flowchart that visualizes every single step in your process, from raw material to the finished product in the customer’s hands. It is one of the most critical lean fundamentals, as it forces you to identify all the non-value-adding activities (waste) in your system, such as wait times, excess inventory, or unnecessary transportation. Once you can see the waste, you can systematically eliminate it.

Moving Ahead

Reducing manufacturing defects is a journey that moves an organization from reactive firefighting to proactive problem-solving. It requires shifting the focus from simply catching mistakes at the end of the line to building a system where defects are prevented from ever occurring.

As we’ve explored, this isn’t about working harder; it’s about working smarter by applying the proven, data-driven DMAIC roadmap of Lean Six Sigma.

Start Your Six Sigma Journey Today

Equip yourself with the skills to identify problems, lead projects, and become an invaluable quality leader in your organization. Find the certification path that matches your career goals.

This structured approach is how leading companies transform their quality challenges into a powerful competitive advantage, leading to lower operational costs, higher customer satisfaction, and a stronger bottom line.

The tools and techniques are powerful, but the real transformation begins with a commitment to continuous improvement. Equipping yourself and your team with the right skills is the most important first step on that path.

- If you’re ready to become a key player in your organization’s quality transformation, explore how a Six Sigma certification can provide you with the expert tools and credentials you need to drive meaningful change.

- For organizations seeking strategic guidance on this journey, exploring a Lean Six Sigma consultation can provide the expert partnership needed to accelerate results and maximize your return on investment.

Frequently Asked Questions (FAQ) About Reducing Manufacturing Defects

Here are answers to some of the most common questions managers and engineers have when tackling quality issues.

A. The most effective way to reduce quality issues is to stop firefighting symptoms and start solving root problems. This requires implementing a systematic framework like Lean Six Sigma, which uses the data-driven DMAIC (Define, Measure, Analyze, Improve, Control) cycle. By focusing on understanding your process, reducing variation, and building a culture of quality, you can prevent defects from occurring in the first place rather than just catching them at the end of the line.

A. While there are many techniques, some of the most common and effective methods include Statistical Process Control (SPC) to monitor process stability, Poka-Yoke (mistake-proofing) to design out the possibility of errors, and Root Cause Analysis (using tools like the 5 Whys and Fishbone Diagrams) to find the true source of a problem. All of these methods are key components of a comprehensive Lean Six Sigma program.

A. While specific defects vary widely by industry, they generally fall into two main categories:

– Functional Defects: These are critical failures where the product does not perform its intended function. For example, a power tool that won’t turn on or a valve that leaks.

– Cosmetic Defects: These are imperfections that affect the product’s appearance but not its core function. Examples include scratches, paint blemishes, or misaligned labels. While less critical than functional defects, they still significantly impact customer perception and brand quality.

A. Lasting improvement requires a dual approach. First, you must adopt a robust quality management system and methodology like Lean Six Sigma. Second, and just as important, you must invest in your people. This means building a culture of employee empowerment and providing them with the right training to become active problem-solvers. This combination of a powerful process and skilled people—led by individuals with qualifications like a Six Sigma Green Belt certification who can manage projects effectively—is the ultimate formula for ensuring sustainable, defect-free manufacturing.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs