What is Special Cause Variation? How to Identify It?

Variations are inherent in any process and the sources of these variations play a crucial role in determining process performance and stability. While common cause variations are predictable and result from the process design itself, special cause variation arise due to unexpected factors and lead to process instability.

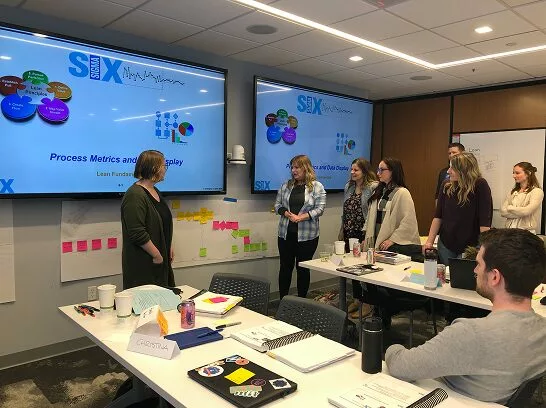

Managing these special cause variations by identifying and eliminating their root causes is an integral part of quality management frameworks like Six Sigma and Lean. By doing so, processes can achieve stability and enhanced capability.

Learn Statistical Process Control (SPC) to detect special cause variation effectively.

Gain the skills needed to eliminate instability and improve process performance with Lean Six Sigma Green Belt Certification.

This enables improved competitiveness through cost reduction, lead time reduction, improved quality, and higher customer satisfaction.

Thus, organizations invest significant efforts in detecting and managing special causes of variation in their business processes.

Understanding Special Cause Variation

Special cause variation refers to fluctuations in a process that happen because of unique or unusual factors that are not normally present.

These unnatural variations are unpredictable and assignable to a specific cause. They indicate that the process has become unstable and is producing defects or undesirable outcomes.

Difference from Common Cause Variation

Common cause variation refers to natural or expected variability that exists in any process. This type of variation happens due to minor, ubiquitous causes that are inherent in the process design.

Common causes lead to random scattering of data points around the mean. On the other hand, special causes produce data points that stand out from the normal pattern of variation and signal that the process is out of control.

While common cause variation indicates a stable process, special cause variation implies instability requiring investigation and corrective action.

Importance in Quality Management

Effective management of special cause variation is crucial for organizations looking to enhance their quality management programs.

By properly identifying and addressing special causes, companies can boost competitiveness, better meet customer expectations, and positively impact financials.

Enhancing Competitiveness with Special Cause Variation

In today’s business landscape, quality has become a key competitive differentiator across industries. Companies that demonstrate consistent product/service quality and continuous improvement initiatives can gain an edge.

The ability to rapidly detect and mitigate special causes of variation enables organizations to enhance process stability.

This prevents the occurrence of unexpected defects and non-conformances which can erode quality perception. Maintaining robust quality standards is essential to stay ahead.

Connecting with Quality-Focused Customers

Customers are increasingly assessing providers based on their quality management record and commitment to zero defects.

By tackling special cause variations through root cause analysis, corrective actions, and control mechanisms. etc. companies can limit unexpected issues that lead to customer dissatisfaction.

This accountability and proactive quality management culture aligns with customer requirements and values.

Communicating such initiatives and results also reassures customers regarding consistency. This helps strengthen loyalty and presents partnership opportunities with quality-focused customers.

Identifying Special Cause Variation

Special cause variation is often difficult to detect without the right analysis tools. Identifying special causes requires going beyond typical process monitoring to specialized statistical techniques.

There are three main methods for recognizing when variation is due to special causes:

Control Charts

Control charts are the most common way to identify special cause variation. Control charts plot data over time with statistically derived upper and lower control limits.

When data points fall outside these control limits, it indicates something unexpected has happened to the process.

This unexpected variance points to special causes rather than expected normal variation.

Common control charts used to monitor special causes include Xbar-R charts, Xbar-S charts, Individual charts, moving range charts, and P charts.

Statistical process control software makes it easy to generate control charts and receive alerts when special causes occur.

Statistical Process Control

Statistical process control (SPC) is an analytical methodology that makes extensive use of control charts.

SPC carefully monitors processes to distinguish between expected and unexpected variations using statistical methods.

By visually separating normal and special cause variations on control charts, SPC provides objective evidence that can pinpoint the timing and magnitude of special causes.

SPC also calculates metrics like Cp and Cpk that quantify overall process variation and process capability.

Tracking these metrics provides further insight into process stability versus areas with heightened special cause variation.

Root Cause Analysis

When control charts or SPC identify special cause variation, the next step is to determine the root cause. Root cause analysis gets to the underlying reason why the unexpected process change happened.

Various tools like the 5 Whys, fishbone diagrams, and failure mode analysis help uncover root causes. Tracing special cause variation back to the root cause is crucial for addressing problems permanently.

Otherwise, the same special cause could keep affecting the process unpredictably.

Implications of Special Cause Variation

Special cause variation can have major implications if left unchecked.

Understanding and properly dealing with special causes is crucial for organizations that want to achieve process stability, improve customer satisfaction, and boost financial performance.

Process Stability with Special Cause Variation

The presence of special cause variation indicates an unstable process. The output and performance metrics of an unstable process fluctuate unpredictably.

This makes the process unreliable and difficult to control. Identifying and eliminating special causes is the first step toward stabilizing a process.

Stable processes have consistent output and are predictable, easier to monitor, and simpler to improve.

Customer Satisfaction

Customers expect consistent quality and on-time delivery of products and services. An unstable process leads to unpredictable product quality and delivery delays which frustrates customers. Fixing special causes improves process stability and capability.

This enables organizations to reliably meet customer expectations and increase satisfaction levels. Satisfied customers lead to repeat purchases and valuable word-of-mouth publicity.

Financial Performance

Unstable processes lead to increased waste, rework, and returns. The additional effort and resources needed to fix these issues drive up costs and hurt profitability.

Special cause variation can also result in production and shipment delays that mean missed revenue opportunities and penalties.

Eliminating special causes reduces costs and improves process efficiency. This directly translates into increased profit margins, higher ROI, and stronger financial performance.

Strategies for Management of Special Cause Variation

Effectively managing special cause variation is critical for organizations looking to improve quality, reduce costs, and boost customer satisfaction.

When a process experiences special cause variation, it indicates an unexpected change that needs to be addressed. Implementing targeted strategies can help get processes back into a state of statistical control.

Corrective Actions

- Once a special cause is identified through statistical process control methods, structured problem-solving methodologies like PDCA (Plan-Do-Check-Act) or DMAIC (Define, Measure, Analyze, Improve, Control) can be utilized to develop corrective actions.

- Brainstorming sessions to determine potential causes and solutions can provide useful insights from team members. Fishbone diagrams are an effective tool to visually map out causes.

- Pilot testing proposed improvements on a small scale first to evaluate potential impact.

- Verify the effectiveness of corrective actions by monitoring the process over time using control charts. Special causes should be removed and variation should return to baseline common cause levels.

Continual Improvement with Special Cause Variation

- Schedule periodic reviews of processes, even in the absence of special causes, to identify opportunities for incremental improvements.

- Utilize lean tools like 5S, poka-yoke, and process mapping to reduce waste and enhance process stability.

- Keep the workforce engaged by encouraging them to share improvement ideas and recognize implementation efforts.

- Consider automating certain process steps to reduce variability induced by human errors.

- Review process performance metrics regularly to ensure improvements are sustained over longer periods.

- Conduct refresher training for employees on methods like statistical process control, Six Sigma, and hypothesis testing.

By taking a structured approach combining short-term corrective actions and long-term continual improvement, organizations can effectively manage special cause variation events.

This drives greater consistency and stability in processes, directly enhancing product quality and customer satisfaction.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs