Supply Chain Cost Optimization: A Blueprint to Slash Costs with Lean Six Sigma

Uncontrolled supply chain expenses are not just a line item on a balance sheet; they are a critical business vulnerability.

From fluctuating fuel prices and geopolitical disruptions to shifting consumer demands, the pressure on supply chain leaders has never been more intense. Simply reacting to these challenges is no longer enough.

To survive and grow, organizations must adopt effective supply chain cost management best practices that build both efficiency and resilience into their operations.

Begin with the Basics

For those new to these powerful concepts, our introductory course provides the perfect overview of the principles behind Lean thinking.

For leaders tasked with navigating this complex environment, the key question is how to move from reactive firefighting to proactive, strategic control.

The answer lies in a proven, data-driven methodology designed to systematically eliminate waste and defects: Lean Six Sigma.

This powerful framework provides the tools to achieve significant supply chain operational cost optimization, transforming your supply chain from a source of anxiety into a well-oiled engine for profitability.

Key Highlights

- Applying Lean Six Sigma for savings.

- Using the DMAIC optimization framework.

- Navigating real-world implementation challenges.

- Maintaining long-term, sustainable improvements.

- Building team expertise through certification.

What is Lean Six Sigma in Supply Chain Cost Optimization?

To truly optimize a supply chain cost, it isn’t enough to be just fast or just high-quality—you must be both. This is where the powerful combination of Lean and Six Sigma comes into play.

Think of them as two sides of the same coin, working together to create a hyper-efficient and reliable operation.

Lean

Lean is all about speed and the relentless elimination of waste. In a supply chain context, this means targeting anything that adds cost without adding value.

This includes excess inventory gathering dust in a warehouse, time wasted waiting for shipments, unnecessary transportation routes, and inefficient processes that slow down the flow of goods.

By adopting the principles of lean manufacturing and applying them to the entire supply chain, organizations can dramatically increase their speed and agility.

Six Sigma

Six Sigma, on the other hand, is a rigorous, data-driven methodology focused on eliminating defects and reducing variability. Its goal is perfection.

In the supply chain, a “defect” can be a late delivery, a damaged product, an incorrect order, or a documentation error. By using statistical analysis to pinpoint the root causes of these problems, Six Sigma ensures that processes are not only fast but also predictable and reliable, leading to significant supply chain efficiency improvements.

When combined, they create a comprehensive system for achieving superior operational efficiency. Lean methodologies clear out the clutter and speed everything up, while Six Sigma ensures that the faster process performs flawlessly.

By simultaneously eliminating waste and errors, companies can achieve dramatic and sustainable reductions in cost.

To effectively apply these ideas, it’s vital to start with a solid grounding in the core principles, which are built upon the concepts detailed in our fundamentals of Lean course.

Start with a Solid Foundation

Before diving into complex projects, ensure you have a firm grasp of the core principles that drive efficiency and eliminate waste.

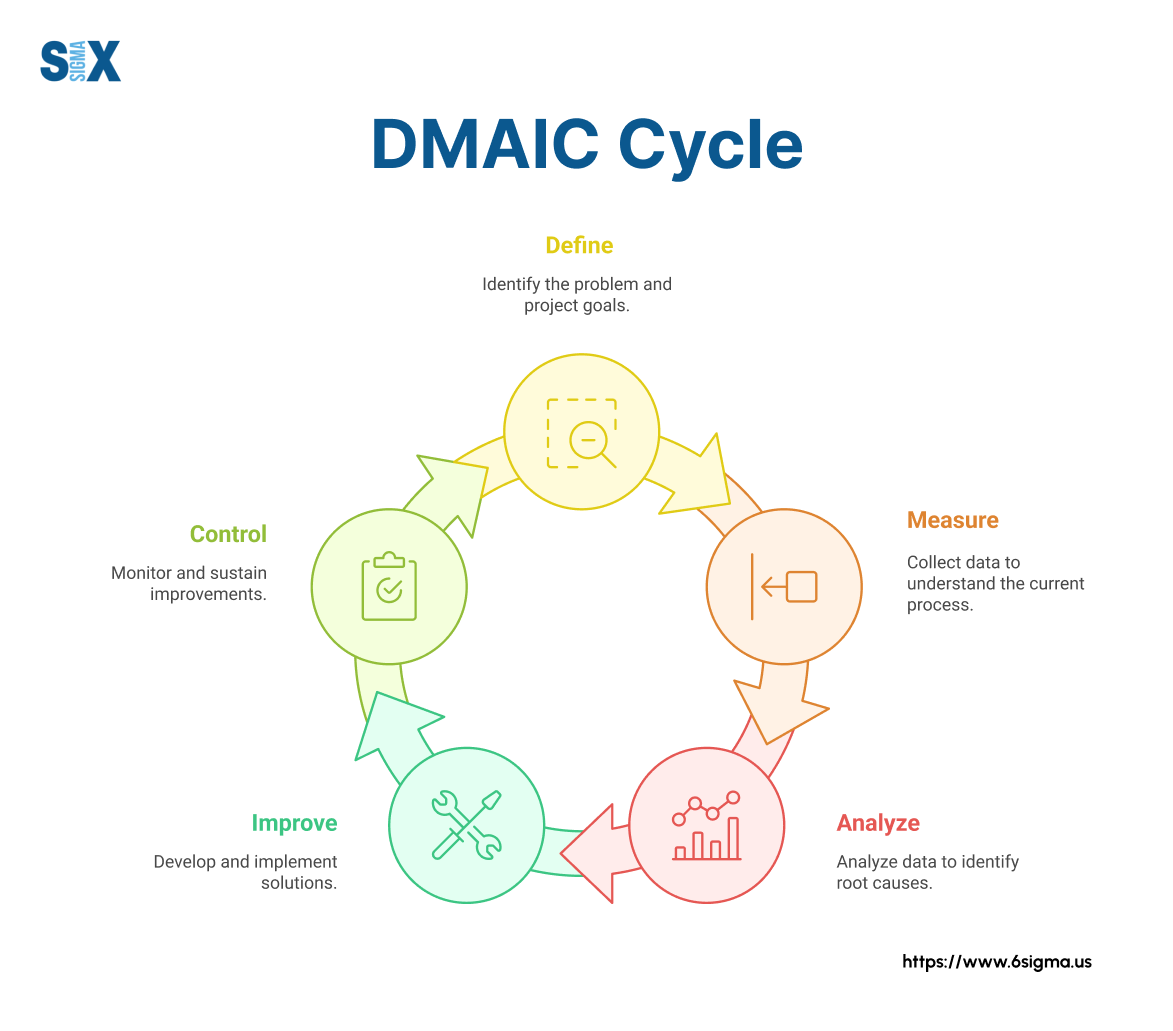

The DMAIC Framework: A 5-Step Roadmap to Supply Chain Savings

Lean Six Sigma’s power doesn’t come from guesswork; it comes from a structured, disciplined process.

The engine that drives every successful project is the DMAIC framework—a five-step roadmap that guides teams from identifying a costly problem to implementing a sustainable, data-driven solution.

Think of it as your GPS for navigating any optimization challenge.

Here is a breakdown of each phase:

- Define: The first step is to clearly define the problem, the project goals, and what a “win” looks like for your customers (both internal and external). A well-defined goal is specific and measurable. For example, a project goal might be: “Reduce the cost-per-mile of our primary shipping lane by 15% within six months without impacting on-time delivery rates.”

- Measure: You cannot improve what you don’t measure. In this phase, the team collects data to quantify the current process performance and establish a baseline. This involves validating the measurement system to ensure the data is accurate. This reliance on hard numbers is where data analytics for supply chain becomes critical, providing a clear picture of the starting point.

- Analyze: With reliable data in hand, the team dives deep to identify the source of the problem. This phase moves beyond symptoms to uncover the underlying issues. To do this, teams perform a thorough root cause analysis, using various tools to ensure they are solving the actual issue, not just patching over a surface-level effect.

- Improve: Once the root cause is identified, the team brainstorms, evaluates, and tests potential solutions. This often involves a detailed cost-benefit analysis to determine the most effective and efficient fix. Whether it’s redesigning a warehouse layout, implementing new software, or engaging in strategic sourcing with new suppliers, the chosen solution is piloted on a small scale before a full rollout.

- Control: An improvement is only valuable if it lasts. The final phase is dedicated to sustaining the gains. This involves updating standard operating procedures (SOPs), training employees on the new process, and implementing a monitoring plan to track performance over time. This ensures the process doesn’t revert to its old, inefficient state and that the cost savings are permanent.

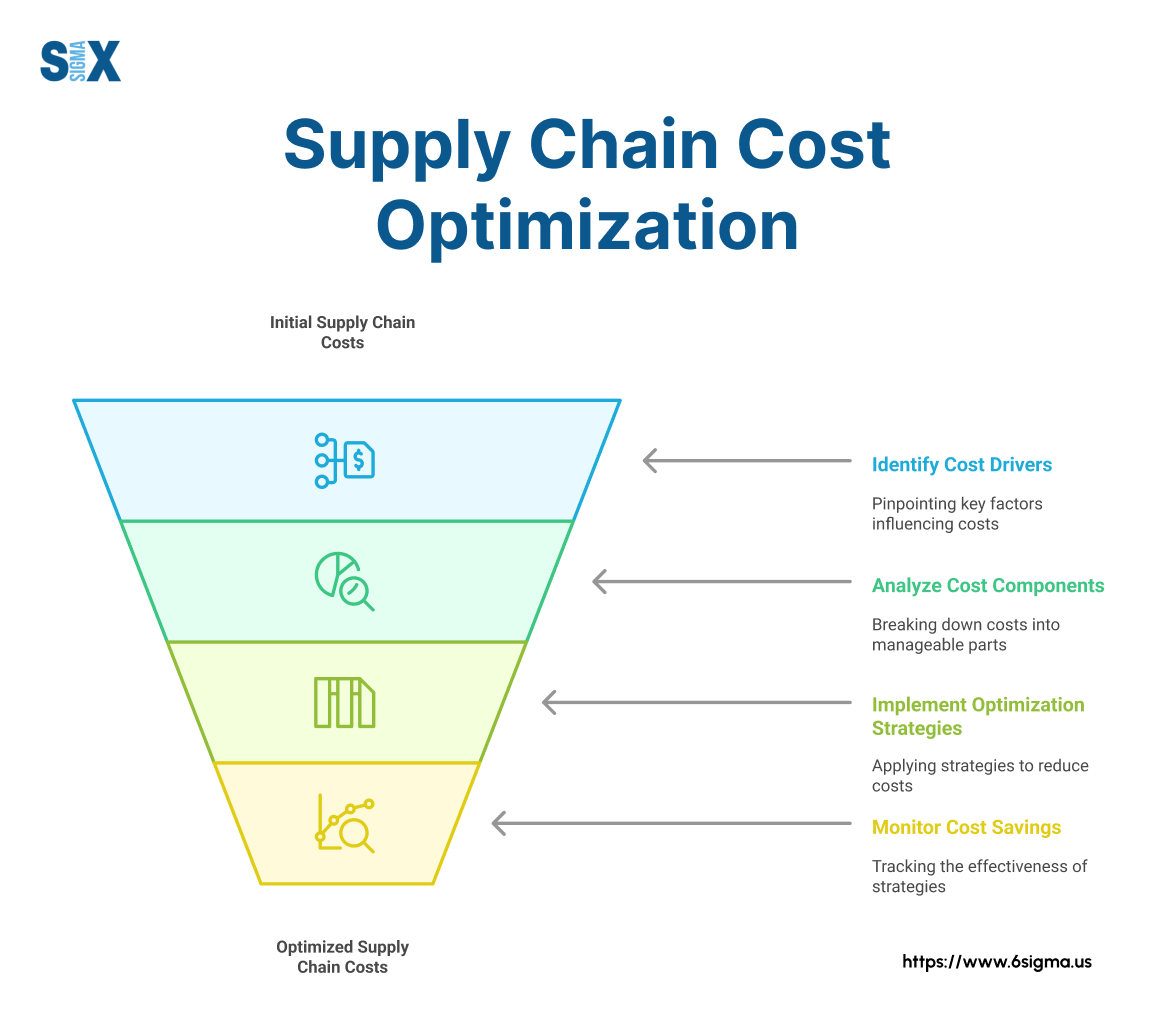

Applying Lean Six Sigma to Key Supply Chain Levers

The true power of Lean Six Sigma is its versatility. The DMAIC framework isn’t just a high-level theory; it can be applied directly to the most critical and cost-intensive parts of your supply chain.

By focusing on these key levers, you can unlock significant savings and operational improvements.

Optimizing Inventory & Warehousing

Warehouses filled with excess inventory represent locked-up cash and a classic form of Lean “waste.” Effective inventory management powered by Lean Six Sigma aims to hold exactly the right amount of stock to meet customer demand without tying up capital.

Techniques like Just-in-Time (JIT) delivery minimize on-hand inventory, while improved demand forecasting prevents the costly cycle of overstocking and stockouts.

Applying Six Sigma principles to warehouse optimization can also dramatically reduce errors in picking and packing, leading to fewer costly returns and higher customer satisfaction. This focus directly contributes to finding major supply chain savings opportunities.

Streamlining Transportation and Logistics

Transportation is often one of the largest expenses in a supply chain budget. Lean Six Sigma provides a powerful toolkit for reducing logistics costs in supply chain operations.

By using data analysis, teams can identify and eliminate inefficient routes, consolidate shipments to maximize container space, and optimize the entire distribution network optimization.

Six Sigma projects can focus on reducing variability in delivery times, making the entire network more predictable. This disciplined approach to logistics management cuts direct transportation costs while simultaneously improving service levels.

Enhancing Procurement and Supplier Relationships

Your supply chain is only as strong as its weakest link, and that often includes external partners. Applying Lean Six Sigma principles to procurement strategies extends beyond your own four walls.

By working with suppliers to improve their quality control, you can reduce the number of defects in incoming materials, saving time and money on inspections and returns.

Strong supplier relationship management (SRM), guided by Lean principles of collaboration and waste reduction, can streamline communication and reduce lead times.

This method of strategic sourcing ensures you are not just buying at the lowest price, but at the best total value for long-term, risk-managed partnerships.

The Reality Check: Overcoming the Barriers to Six Sigma Success

While Lean Six Sigma is an incredibly powerful methodology, it’s not a magic wand. Real-world implementation comes with obstacles, and acknowledging them is the first step toward overcoming them.

Many organizations stumble not because the tools are flawed, but because they underestimate the human and cultural side of change.

What are the biggest barriers to successful Six Sigma adoption?

Even the best-laid plans can fail if they hit one of these common roadblocks. The most significant barriers are rarely technical; they are organizational.

They typically include:

- Lack of Leadership Buy-in: If senior leaders view Six Sigma as a “shop-floor initiative” instead of a core business strategy, it will be starved of the resources, attention, and authority needed to succeed.

- Insufficient Resources: Meaningful projects require dedicated time from your best people, as well as potential investments in technology or training. Treating Six Sigma as a side project is a recipe for failure.

- A Culture Resistant to Change: Perhaps the biggest barrier is a culture that fears data-driven scrutiny or is simply comfortable with the status quo. If “we’ve always done it this way” is a common refrain, you have a major hurdle to clear.

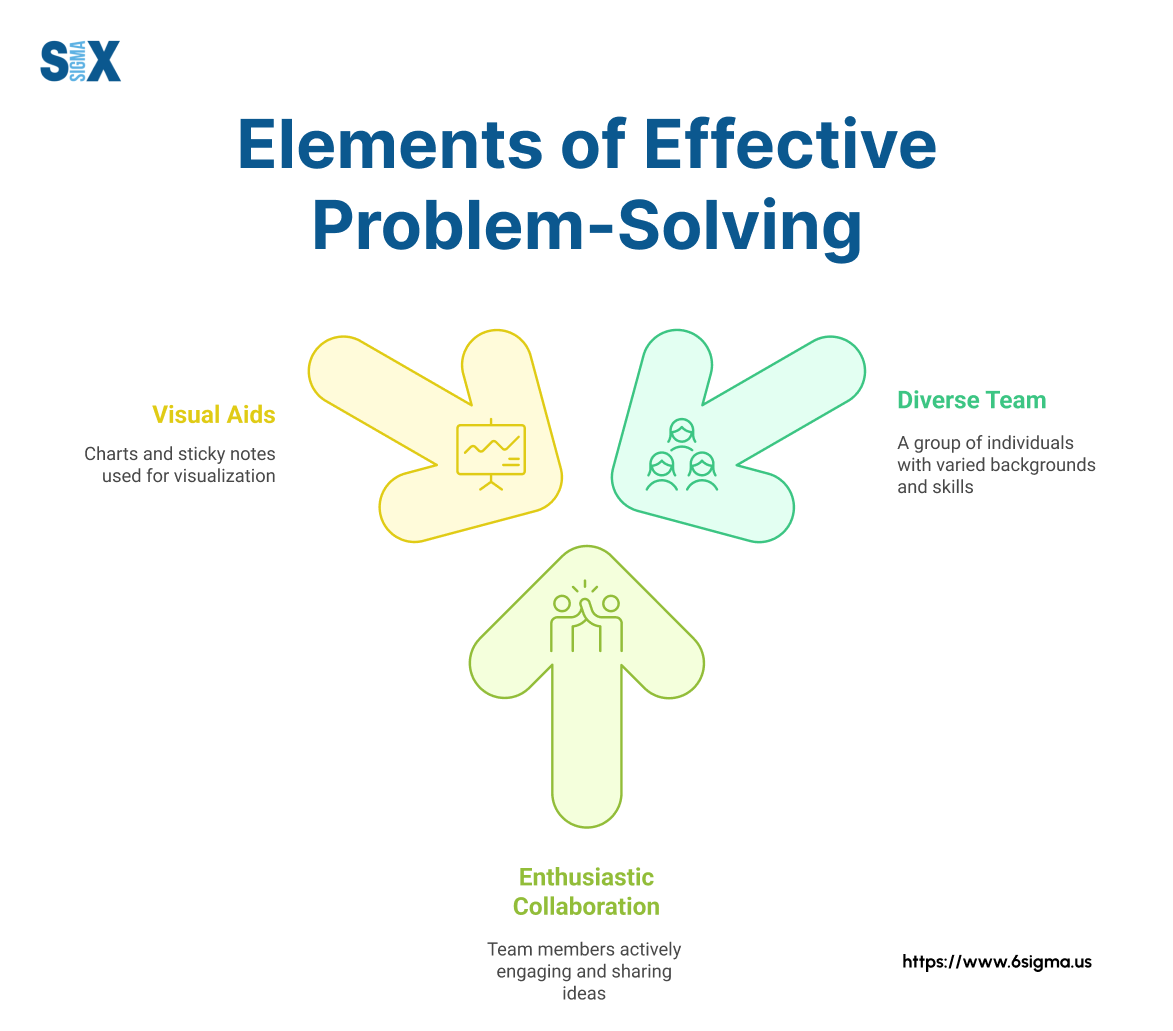

How do you overcome resistance to change in Six Sigma initiatives?

You cannot command a cultural shift; you have to cultivate it. Overcoming resistance hinges on clear communication, transparency, and most importantly, empowerment.

The goal is to do Six Sigma with your teams, not to them. One of the most effective strategies is to turn skeptics into champions by building internal expertise from the ground up.

Creating broad awareness with a foundational six sigma white belt certification for all team members, and empowering key employees with the problem-solving tools taught in a six sigma yellow belt certification program, demystifies the process and fosters buy-in at the grassroots level.

When employees feel they own the process, resistance transforms into engagement.

What are the challenges with change management in Six Sigma?

Beyond initial resistance, effective change management requires skilled leadership to navigate the human side of a project.

Employees may fear that “optimization” is a code word for layoffs, or they may struggle to adopt new processes. A great project leader knows how to build momentum by celebrating small wins and creating a safe environment for teams to learn and adapt.

This is why project leads who can manage both the technical analysis and the team dynamics are so valuable.

Equipping these leaders with the comprehensive project management and change management skills taught in a six sigma green belt certification is often critical for navigating these complex human challenges and ensuring a project’s success.

Turn Your Team into Champions of Change

The best way to overcome resistance is to build confidence and skills at the grassroots level with our Lean Six Sigma Yellow Belt Certification.

Beyond the Project: How to Maintain Improvements for the Long Term

One of the most common pitfalls in any optimization effort is “project fizzle-out.” A team works hard for months, achieves a significant improvement, and celebrates a successful project.

But six months later, old habits have crept back in, and the process has slowly reverted to its previous, inefficient state.

An improvement is only valuable if it lasts. This is why the ‘Control‘ phase of DMAIC is arguably the most critical for achieving real, long-term returns.

Sustaining your hard-won gains requires building a permanent infrastructure around the new, improved process.

This isn’t just about telling people to “do things differently”; it’s about making the new way the easiest and most logical way to work.

This involves three key elements:

- Standard Operating Procedures (SOPs): The new process must be clearly documented. Well-written SOPs serve as the official playbook, ensuring that everyone—including new hires—understands and follows the optimized workflow.

- Ongoing Performance Monitoring: Dashboards and Key Performance Indicators (KPIs) are established to track the health of the new process. This allows leaders to spot any negative trends early and take corrective action before they become major problems.

- A Culture of Continuous Review: The project team disbands, but the process owners must hold regular reviews to analyze performance data. This embeds supply chain cost management best practices into the company’s DNA and fosters a culture that is always looking for the next opportunity to improve.

By making these controls a core part of your management system, you ensure that today’s savings are permanent. This has a powerful ripple effect, improving everything from service levels to working capital optimization.

For organizations seeking to build this robust infrastructure from the ground up, a formal lean six sigma consultation can provide the strategic framework and expert guidance needed to ensure today’s projects translate into lasting profitability.

The Role of Certification in Building a World-Class Team

How do you build and sustain a culture of continuous improvement?

You invest in your people. Certification is the most effective way to build a capable, self-sufficient optimization team.

It provides a common language, a proven toolkit, and a clear career path for employees, transforming continuous improvement from a temporary initiative into a permanent, in-house capability.

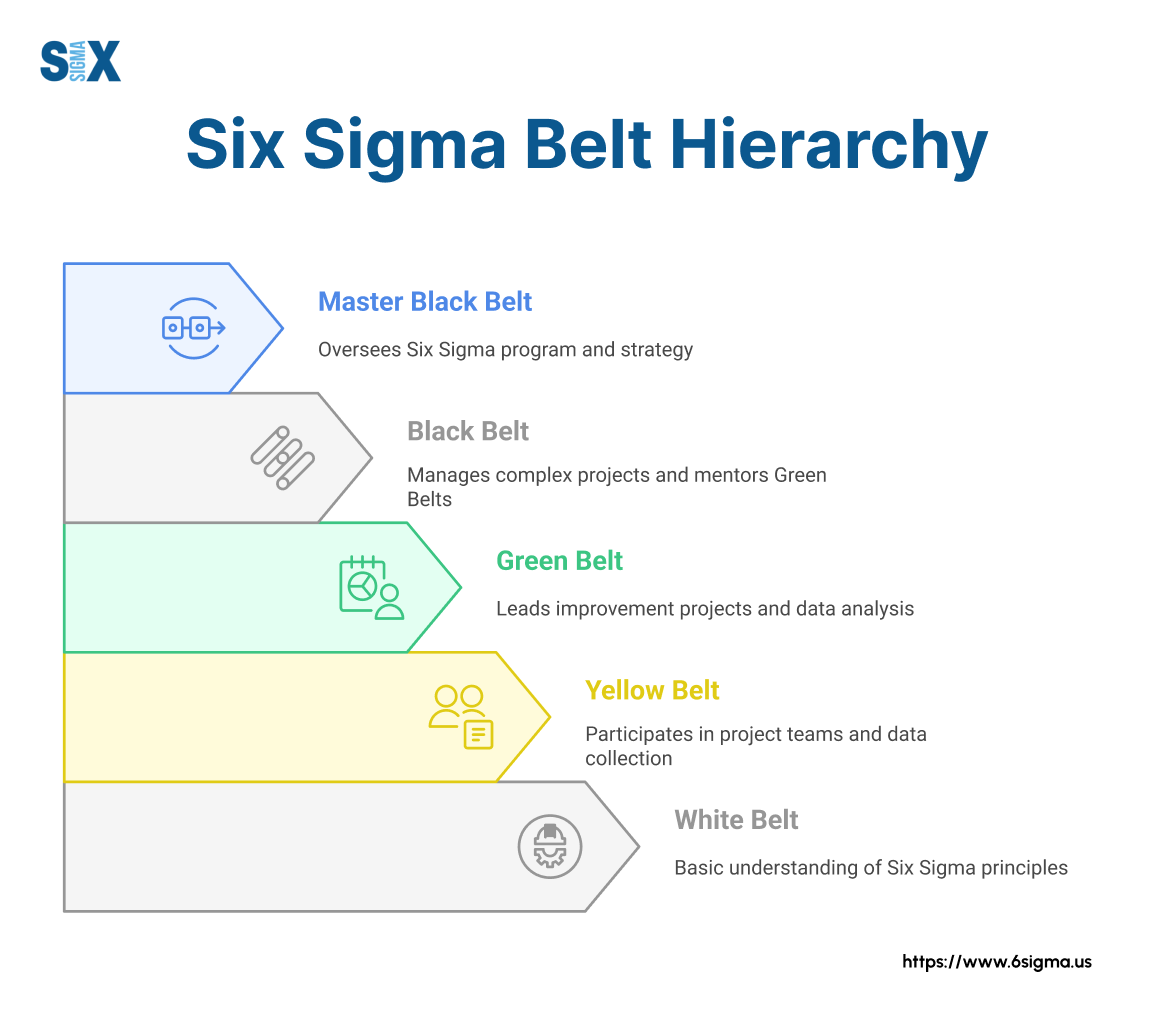

A structured “Belt” system is used to signify different levels of expertise and responsibility within the organization.

- Green Belts: These are the project leaders on the front lines of your optimization efforts. They lead smaller-scale improvement projects within their functional areas while still performing their regular job duties. A six sigma green belt certification equips them with the essential tools to lead teams, manage projects, and deliver measurable results.

- Black Belts: These are highly trained, full-time experts who lead an organization’s most complex and critical improvement projects. They serve as mentors and coaches to Green Belts and are the technical leaders of the Lean Six Sigma program. Earning a six sigma black belt certification signifies a high level of mastery in statistical analysis and change management.

- Master Black Belts: At the pinnacle of the structure is the Master Black Belt. These individuals are the strategic architects of the entire continuous improvement program. They train and mentor Black Belts, work with senior leadership to align projects with strategic goals, and ensure the methodology is applied consistently and effectively across the enterprise. The six sigma master black belt certification prepares individuals for this vital strategic role.

By investing in this hierarchy of expertise, an organization creates a powerful, self-sustaining engine for innovation and efficiency.

From Cost Center to Strategic Asset

True supply chain cost optimization is not about arbitrarily slashing budgets or making reactive, short-term cuts. It’s about a strategic transformation.

It means methodically re-engineering your processes to be faster, more reliable, and free from the waste that quietly drains profitability.

By embracing the principles of Lean Six Sigma and preparing for its real-world challenges, you can systematically build an operation that is not just leaner, but fundamentally stronger.

This journey—from defining a problem with the DMAIC framework to building a certified team of in-house experts—is how you move your supply chain from a reactive cost center to a proactive, strategic asset.

By embracing this data-driven culture, you create a powerful engine for profitability and a durable competitive advantage that is difficult for others to replicate.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs