Out of Control Action Plan (OCAP): A Proven Framework for Sustained Process Control

Keeping methods on track and actually meeting goals is incredibly important.

Even the best-designed and implemented processes can experience hiccups or drifts that undermine results and productivity.

This is where having an Out of Control Action Plan or OCAP makes a difference – it’s an essential contingency map for organizations to quickly tackle and fix problems when procedures surpass normal limits.

The origins of an OCAP can be traced back to key steps in Six Sigma for maintaining enhancements and ensuring stability long-term.

However, it proves useful far beyond traditional factory settings, making it a multi-purpose and invaluable resource for any business aiming to maximize returns through constant upgrading.

Whether through consistent modifications or unforeseen disruptions, deviations will arise.

An Out of Control Action Plan (OCAP) gives teams a plan B already in place to stay ahead of the curve, identify root causes and prevent issues from worsening while keeping operations on track overall. This readies companies for whatever challenges materialize next.

Key Highlights

- Understand the fundamental concepts and purpose of an Out of Control Action Plan (OCAP)

- Explore the significance of OCAP in the Six Sigma Control phase

- Gain insights into key OCAP components

- Learn the step-by-step Out of Control Action Plan (OCAP) implementation process.

- Discover best practices for successful OCAP execution.

- Examine case studies illustrating OCAP’s applicability across diverse industries.

- Appreciate the importance of treating Out of Control Action Plan as a living document and integrating it into an organization’s quality management system

What is an Out of Control Action Plan (OCAP)?

In the relentless pursuit of process excellence, even the most meticulously designed systems can veer off course, compromising performance and heightening the risk of adverse outcomes.

Definition of Out of Control Action Plan (OCAP)

An Out of Control Action Plan (OCAP) is a structured, proactive approach that serves as an emergency plan or contingency control chart.

Its primary purpose is to outline clear steps and procedures for swiftly identifying, containing, and correcting situations where a process exceeds predetermined control limits, signaling an out-of-control state.

With a Six Sigma Green Belt certification, you can lead such analyses, as the program covers process control tools like control charts.

Purpose of Out of Control Action Plan (OCAP)

The fundamental objective of an OCAP is to provide a roadmap for restoring processes to their intended state of statistical control, minimizing the impact of variations, and ensuring outputs remain within acceptable limits.

By proactively addressing deviations, an OCAP helps organizations maintain process stability, reduce waste, and uphold quality standards.

When is an Out of Control Action Plan Needed?

An Out of Control Action Plan (OCAP) comes into play when monitoring tools, such as control charts, indicate that a process has exceeded its established control limits, signaling an out-of-control situation.

These control limits are predetermined thresholds that define the acceptable range of variation within a process. When a process breaches these limits, it is considered unstable, and an OCAP must be implemented to correct the issue promptly.

The Importance of an Out of Control Action Plan (OCAP) for Process Improvement

The OCAP has solidified its position as an indispensable tool, particularly within the realm of Six Sigma’s Control phase, where professionals with a certification in six sigma are trained to implement such strategies effectively.

Its far-reaching implications extend beyond mere corrective action, making it a critical component of any organization’s journey toward continuous improvement and sustained excellence.

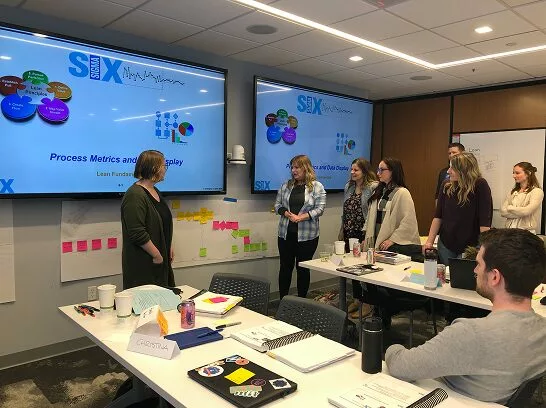

OCAP as Part of Six Sigma’s Control Phase

Within the Six Sigma framework, the Control phase is dedicated to ensuring that improvements made during previous phases are sustained over time.

An OCAP is a core component here, and our Six Sigma certification programs emphasize its role in maintaining statistical process control.

Out of control action plan plays a pivotal role in this phase, providing a structured approach to monitoring process performance and swiftly addressing any deviations that may arise.

Benefits of Using an Out of Control Action Plan (OCAP)

The implementation of an OCAP yields numerous benefits that contribute to organizational effectiveness and efficiency:

- Data-driven Decision-making: By leveraging statistical tools like control charts, an OCAP promotes data-driven problem identification and analysis, enabling teams to make informed decisions based on factual evidence rather than assumptions.

- Waste Reduction: Out-of-control processes often lead to the production of defective products, excessive rework, or unnecessary downtime, all of which contribute to waste. An OCAP helps minimize these sources of waste by promptly addressing root causes and restoring processes to their optimal state.

- Clear Action Plan: The OCAP provides a well-defined roadmap for addressing out-of-control situations, eliminating ambiguity, and ensuring that teams have a consistent approach to follow. This clarity of action promotes efficient problem-solving and minimizes the risk of further complications.

Role of OCAP in Continuous Improvement and Quality Management

The OCAP is not merely a reactive tool but also plays a proactive role in driving continuous improvement and quality management within organizations.

By identifying process weaknesses and implementing corrective actions, an OCAP contributes to the ongoing refinement and optimization of processes.

Key Out of Control Action Plan (OCAP) Concepts

To fully appreciate the power and effectiveness of an Out of Control Action Plan or OCAP, it is essential to understand several key concepts that underpin its design and implementation.

These fundamental principles provide the foundation upon which successful OCAPs are built, enabling organizations to maximize their impact and achieve sustainable process control.

Control Charts for Monitoring Process Performance

OCAP is the concept of control charts, a statistical tool used to monitor process performance over time.

Control charts visualize process data, allowing teams to identify when a process begins to deviate from its expected performance range, as indicated by the control limits.

These control limits represent the boundaries within which a process is considered stable and in control. When data points fall outside these limits, it signals an out-of-control situation, triggering the need for an OCAP.

Out-of-control Situations and Causes

An out-of-control situation refers to a state where a process exhibits unacceptable levels of variation, resulting in outputs that do not meet predefined quality standards or performance expectations.

These situations can arise due to a multitude of factors, including equipment malfunctions, operator errors, raw material inconsistencies, or changes in environmental conditions.

Identifying the root causes of these out-of-control situations is crucial for developing effective corrective actions within an OCAP.

Containment actions

When an out-of-control situation is detected, the immediate priority is to contain the issue and prevent further propagation of defects or deviations.

Containment actions are the initial steps taken within an OCAP to isolate the problem and minimize its impact on downstream processes or customers.

Examples of containment actions may include halting production, quarantining affected materials, or implementing temporary workarounds until root causes can be addressed.

Out of Control Action Plan (OCAP) Implementation Process

Implementing an effective OCAP requires a structured and systematic approach to ensure that out-of-control situations are addressed promptly and comprehensively.

This process involves a series of well-defined steps that guide teams from problem identification to root cause analysis, corrective action implementation, and effectiveness verification.

Step 1: Identify the Problem

The first step in the OCAP implementation process is to identify the existence of an out-of-control situation. This is typically achieved through the continuous monitoring of process performance using statistical tools like control charts.

By analyzing control chart data, teams can detect when a process exceeds its control limits, signaling the need for intervention.

Step 2: Contain the Issue

Once an out-of-control situation has been identified, immediate action must be taken to contain the issue and prevent further propagation of defects or deviations.

This step may involve halting production, quarantining affected materials, implementing temporary workarounds, or taking other measures to isolate the problem and minimize its impact on downstream processes or customers.

Step 3: Root Cause Analysis

After containing the issue, the next critical step is to conduct a thorough root cause analysis to identify the underlying factors contributing to the out-of-control situation.

This analysis can leverage various problem-solving tools and techniques, such as Failure Mode and Effects Analysis (FMEA), the 5 Whys method, or Ishikawa (fishbone) diagrams.

For a deeper expertise, enroll in our Root Cause Analysis certification program, that equips professionals with systematic methods to uncover underlying issues.

By studying the root causes, teams can develop targeted corrective actions to address the underlying issues rather than merely treating symptoms.

Corrective and Preventive Actions

Once the root causes of an out-of-control situation have been identified, the next stage in the Out of Control Action Plan (OCAP) implementation process involves developing and implementing corrective and preventive actions to address the underlying issues and prevent future occurrences.

Developing Solutions to Address Root Causes

Based on the insights gained from the root cause analysis, teams can develop targeted solutions to address the identified root causes.

These solutions may involve process modifications, equipment upgrades, personnel training, or changes in material sourcing, among other actions.

The key is to ensure that the proposed solutions directly target the root causes and are feasible to implement within the organization’s constraints.

Implementing Corrective Actions

With the solutions in place, the next step is to implement the corrective actions outlined in the OCAP.

This may involve coordinating cross-functional efforts, allocating necessary resources, and ensuring proper communication and training for affected personnel.

Clear roles, responsibilities, and timelines should be established to facilitate a smooth and effective implementation process.

Preventive Actions to Prevent Recurrence

In addition to corrective actions, an OCAP should also incorporate preventive measures to mitigate the risk of similar out-of-control situations occurring in the future.

These preventive actions may include revising standard operating procedures, implementing preventive maintenance schedules, enhancing operator training programs, or establishing more robust monitoring and control mechanisms.

Verifying OCAP Effectiveness

Once corrective and preventive actions have been implemented, it is crucial to verify their effectiveness in bringing the process back into a state of statistical control.

This verification step ensures that the Out of Control Action Plan has achieved its intended objectives and provides valuable insights for future improvement efforts.

Monitoring Corrective Action Results

The effectiveness of the corrective actions implemented through the OCAP should be monitored and evaluated using appropriate data collection and analysis techniques.

Bringing the Process Back into Control

If the monitoring activities indicate that the corrective actions have been successful in bringing the process back within its predetermined control limits, the OCAP can be considered effective, and the process can be considered in a state of statistical control.

However, if the process remains out of control or new issues arise, further analysis and adjustments may be necessary.

Documenting OCAP Execution

Thorough documentation of the OCAP execution process is essential for several reasons.

First, it provides a historical record of the actions taken, the root causes identified, and the effectiveness of the corrective and preventive measures implemented.

This documentation can serve as a valuable reference for future occurrences of similar issues or training purposes.

Examples and Case Studies of Out of Control Action Plan (OCAP)

To further illustrate the versatility and practical application of OCAPs, let’s explore a few examples and case studies from several industries.

These examples will shed light on how organizations have leveraged OCAPs to address out-of-control situations, restore process stability, and drive continuous improvement.

Manufacturing Process OCAP Example

In a precision manufacturing facility producing automotive components, a sudden increase in defect rates triggered the implementation of an Out of Control Action Plan.

Through control chart analysis, the team identified that a critical machining operation was producing parts outside the specified tolerances.

They promptly contained the issue by quarantining the affected parts and halting production on the affected line.

Root cause analysis revealed that a recent equipment maintenance activity had inadvertently introduced a misalignment in the machining setup, leading to the observed defects.

Corrective actions included recalibrating the equipment, revising the maintenance procedures, and implementing more stringent verification checks. Preventive measures involved scheduling regular calibration intervals and enhancing operator training on proper setup and verification techniques.

Service Industry Application

In the service industry, OCAPs can be equally valuable for addressing out-of-control situations that may impact customer satisfaction and operational efficiency.

Consider a hotel that experienced a spike in customer complaints regarding poor housekeeping services. An OCAP was initiated to investigate the root causes of the issue.

Best Practices for Successful Out of Control Action Plan Implementation

While the OCAP framework provides a structured approach to addressing out-of-control situations, its effectiveness ultimately depends on the diligence and precision with which it is implemented.

Understanding Customer Needs

Before embarking on any process improvement effort, it is crucial to have a deep understanding of customer needs and requirements.

This customer-centric mindset should permeate every aspect of the OCAP implementation, ensuring that corrective and preventive actions are aligned with delivering superior value to the end customer.

Regularly seeking customer feedback, analyzing voice-of-the-customer data, and involving customers in the improvement process can provide invaluable insights and help prioritize actions that directly address their needs.

A Clear Plan and Team Alignment

Successful OCAP implementation hinges on having a clear and well-defined plan that outlines roles, responsibilities, timelines, and specific actions to be taken.

This plan should be communicated effectively to all stakeholders, fostering team alignment and ensuring a shared understanding of the objectives and expectations.

Establishing a cross-functional team with representatives from various departments can further enhance collaboration, facilitate information sharing, and promote buy-in across the organization.

Testing and Measuring Results

Throughout the Out of Control Action Plan (OCAP) implementation process, it is essential to continuously test and measure the results of corrective and preventive actions.

This data-driven approach enables teams to assess the effectiveness of their interventions, make necessary adjustments, and validate that the process has been brought back into a state of statistical control.

Overcoming Challenges

Despite the well-documented benefits of OCAPs, their implementation can sometimes encounter challenges and resistance within organizations.

Overcoming these obstacles requires a proactive approach, effective change management strategies, and a deep understanding of the key elements that contribute to successful OCAP execution.

Handling Resistance to Change

Change, even when it promises improvement, can be met with resistance from individuals or groups within an organization.

This resistance may stem from fear of the unknown, concerns about increased workload, or a general reluctance to deviate from established practices.

Addressing resistance to change requires open communication, active listening, and the involvement of all stakeholders throughout the OCAP implementation process.

Key Elements for an Effective OCAP

Drawing from my extensive experience, I’ve identified several key elements that contribute to the effectiveness of an OCAP:

1. Comprehensive Training: Ensuring that all team members involved in the OCAP implementation process receive comprehensive training on the tools, techniques, and methodologies employed is crucial.

This training should cover statistical process control, root cause analysis methods, and effective problem-solving strategies.

Roles requiring deep process control expertise, such as those held by Six Sigma Green Belt certified professionals , often lead these efforts.

2. Data-driven Decision-making: Basing decisions on factual data and statistical evidence, rather than assumptions or anecdotal evidence, is imperative for the success of Out of Control Action Plan.

This data-driven approach promotes objectivity, minimizes biases, and ensures that corrective actions address the true root causes of out-of-control situations.

3. Cross-functional Collaboration: Out-of-control processes often involve multiple departments and functional areas within an organization.

Fostering cross-functional collaboration and breaking down silos can enhance information sharing, leverage diverse expertise, and promote a holistic view of the process and its interdependencies.

4. Management Support: Strong leadership and management support are essential for providing the necessary resources, authority, and commitment required for successful OCAP implementation.

Management’s active involvement and visible endorsement can help overcome resistance to change and reinforce the importance of the improvement efforts.

Involving Subject Matter Experts

While the OCAP framework provides a structured approach, the complexity of some out-of-control situations may require the involvement of subject matter experts with specialized knowledge or expertise.

These experts can provide valuable insights, offer alternative perspectives, and contribute to the development of effective corrective and preventive actions.

Involving subject matter experts early in the OCAP implementation process can accelerate problem-solving, leverage best practices from other industries or domains, and enhance the overall effectiveness of the solutions implemented.

Continuous Out of Control Action Plan (OCAP) Improvement

The OCAP is not a one-time exercise but rather a continuous journey of process improvement and optimization. As organizations evolve, new challenges arise, and processes change, Out of Control Action Plan (OCAP) must adapt and evolve to remain relevant and effective.

Embracing a mindset of continuous improvement is essential to maximize the long-term benefits of OCAPs and sustain a culture of excellence.

Treating OCAP as a Living Document

An OCAP should be treated as a living document, subject to regular review and updates based on new insights, lessons learned, and changing process dynamics.

As corrective and preventive actions are implemented, their effectiveness should be closely monitored, and any necessary adjustments should be incorporated into the OCAP.

Updating Based on new Process Knowledge

As organizations gain new knowledge and insights about their processes, either through continuous improvement efforts, technological advancements, or changes in regulatory or industry standards, the OCAP should be updated accordingly.

This may involve revising control limits, incorporating new monitoring techniques, or introducing new problem-solving methodologies.

Regularly reviewing and updating the Out of Control Action Plan based on the latest process knowledge ensures that it remains effective and relevant, enabling organizations to stay ahead of potential out-of-control situations.

Integrating OCAP into the Quality Management System

To truly embrace a culture of continuous improvement and process excellence, organizations should integrate the OCAP into their overall quality management system.

By aligning the OCAP with existing quality policies, procedures, and standards, organizations can ensure a consistent and coordinated approach to addressing out-of-control situations across all processes and departments.

This integration also facilitates the sharing of best practices, promotes cross-functional collaboration, and reinforces the importance of process control and improvement throughout the organization.

Conclusion

In the constant pursuit of process perfection, having an Out of Control Action Plan or OCAP proves a powerful resource. It enables organizations to maintain stability, reduce waste and drive ongoing upgrades.

Over my lengthy career helping companies as a Master Black Belt, I’ve directly witnessed the amazing changes a well-designed and properly used OCAP can bring.

By laying out clear steps for finding, containing and correcting problems, the OCAP empowers teams to proactively address issues before they worsen. This minimizes mistakes or method variations while quickly restoring regular function.

Those seeking to master these tools should enroll in our Six Sigma certification programs, which integrates OCAP into broader process excellence strategies.

But its value goes beyond just fixing things – it plays a key role fostering cultures of ongoing learning, flexibility and quality priorities within companies.

The Out of Control Action Plan or OCAP stands as proof of the strength in forward-thinking problem-solving and relentless progress.

Having a plan for when plans go off course sets teams up to withstand challenges while still maximizing performance into the future.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs