What is Six Sigma?

Six Sigma is a methodology used to improve business processes by utilizing statistical analysis rather than guesswork. Processes are improved by controlling variation and understanding the intricacies within them. This results in more predictable and profitable business processes as it provides a clear path and tools to find the underlying causes of mistakes and create reliable long-term improvements.

Its core aim is straightforward: improve processes by cutting down on variation, mistakes, and waste. By measuring defects and analyzing the data, you can systematically work towards making processes highly reliable and nearly error-free.

It operates on the principle that if you can measure how many “defects” exist in a process, you can systematically figure out how to eliminate them and get as close to “zero defects” or perfection as possible through data-driven decisions.

6Sigma.us is at the forefront of Six Sigma certification and consulting services. We assist organizations with all aspects of the implementation process from training Six Sigma Champions to certifying employees at advanced levels (Green Belt, Black Belt and Master Black Belt).

We provide hands-on implementations of Six Sigma & Lean at our locations, at your workplace, online or through live virtual classes with our expert Master Black Belt instructors.

Not Sure Where to Start? Let Us Help!

Don’t just read about improvement – start driving it. Take the next step with 6Sigma.us.

Get Your Six Sigma Certification with 6Sigma.us

Contact us directly! We’ll help you to select the appropriate training and certification option.

Why Should I Learn Six Sigma?

Adopting Six Sigma isn’t just about learning a new methodology; it’s about driving real, measurable improvements that impact both the bottom line and the people involved. Its structured, data-driven approach delivers compelling advantages for organizations and significant career boosts for individuals.

Key Benefits for Organizations

Implementing a Six Sigma culture and methodology can fundamentally transform how an organization operates, leading to tangible results:

Improved Employee Morale & Engagement: Empowering employees at all levels to identify problems and contribute to solutions (especially through Green Belt and Yellow Belt participation) can significantly boost morale. People feel valued and invested when they can actively improve their own work processes.

Reduced Costs: By rigorously identifying and eliminating defects, waste (like rework, scrap, unnecessary steps), and process variations, Six Sigma directly cuts operational costs. Fewer errors mean less money spent fixing mistakes. Organizations implementing Six Sigma have reported validated bottom-line savings of millions of dollars each year.

Improved Efficiency & Productivity: Streamlining processes, removing bottlenecks, and standardizing workflows leads to faster cycle times and increased output with the same or fewer resources. Teams work smarter, not just harder.

Enhanced Customer Satisfaction & Loyalty: Focusing on the Voice of the Customer (VOC) ensures that improvements directly address what matters most to your clients. Delivering higher quality products/services with greater consistency builds trust and loyalty.

Better Decision Making: Moving away from guesswork, Six Sigma embeds data-driven analysis into the organizational culture. Leaders and teams make more informed, objective decisions based on facts, leading to more predictable and successful outcomes.

Sustained Quality Improvement & Competitive Advantage: Six Sigma isn’t a one-off fix. Its ‘Control’ phase and principles of continuous improvement help organizations maintain gains and build a culture that consistently seeks better ways of working, creating a lasting competitive edge.

A Brief History & Evolution of Six Sigma

Engineer Bill Smith, often called the “Father of Six Sigma,” started using the methodology and concepts while at Motorola. The methodology used today was formalized during the 90’s at Allied Signal (now Honeywell) through the leadership of CEO Lawrence Bossidy and General Electric (GE) with CEO Jack Welch. These organizations developed the statistical concepts and the structured approach aimed at achieving quantifiable quality improvements, directly linking fewer defects to reduced costs and increased customer satisfaction.

While Motorola formalized Six Sigma, its foundations rest on the work of earlier quality management pioneers. Thinkers like:

- W. Edwards Deming: Championed statistical process control (SPC), continuous improvement (PDCA cycle), and a system-focused view of quality.

- Joseph M. Juran: Emphasized the “Quality Trilogy” (quality planning, quality control, quality improvement) and the human side of quality management.

Their principles deeply influenced the development of Six Sigma’s data-centric and structured nature.

The Rise of Lean Six Sigma

Over time, practitioners realized the natural synergy between Six Sigma’s focus on defect reduction and Lean principles’ focus on waste elimination and process flow.

This led to the integration known as Lean Six Sigma, combining the strengths of both methodologies for even greater efficiency and effectiveness. Today, Six Sigma continues to evolve, incorporating new tools and adapting to fields like data science and Agile methodologies.

Why Does History Matter?

Understanding this evolution isn’t just academic. It shows that Six Sigma isn’t a fleeting trend but a robust methodology built on proven principles and refined through decades of real-world application.

Its history provides context for why certain tools are used and why the structured approach is so critical to achieving repeatable, sustainable results.

Question: Putting the textbook definitions aside, how would you explain the practical essence of Six Sigma to someone on the shop floor or in a service center, based on what you’ve seen it achieve?

Answer: Six Sigma, at its core, is about solving problems with unknown solutions in a way that sticks. On the shop floor or in a service center, it’s not about charts and Greek letters — it’s about fixing the stuff that slows us down, causes defects, or frustrates customers. It does not make problems go away, but helps us be prepared for anything that occurs, because it follows a scientific and systematic approach.

It’s walking into a process, seeing the waste & the variability, the constant firefighting, and saying: ‘We can do better — and here’s how we prove it.’

Six Sigma gives us the mindset and the tools to make decisions based on facts, and verified numbers, not gut feelings. You’ve probably seen it in action without realizing it — when a team finally gets to identify the root cause of an issue, implements a change, and suddenly the noise disappears.

That’s Six Sigma. It’s discipline, it’s data, and it’s relentless focus on what actually matters to the people doing the work and the customers who receive it.

– David Leiva, Master Black Belt, SixSigma.us

Want to Learn Six Sigma?

Build your six sigma foundation and learn practical skills to drive process improvement.

The Core Principles of Six Sigma

Six Sigma is more than just a set of tools; it’s a philosophy built on fundamental principles that guide every action and decision within the methodology. Understanding these core tenets is essential for truly harnessing its power for process improvement and achieving breakthrough results.

Here are the guiding principles that form the bedrock of Six Sigma:

- Focus Intensely on the Customer:

At the heart of Six Sigma lies the Voice of the Customer (VOC). This principle dictates that all decisions, goals, and improvement efforts must be driven by understanding and meeting customer needs and requirements. What defines “quality” or a “defect” is ultimately determined by the customer. Actively seeking, analyzing, and acting upon customer feedback is paramount.

- Make Data-Driven Decisions:

Opinions, assumptions, and gut feelings are replaced by hard facts and statistical analysis. Six Sigma emphasizes the need to measure everything relevant to a process and its defects. Data is collected and rigorously analyzed to identify root causes and key drivers of variation (such as differences in suppliers, equipment workers and departments). Potential solutions are evaluated, and improvements are verified. This ensures decisions are objective and lead to predictable outcomes.

- Maintain a Strong Process Focus:

Six Sigma recognizes that problems and defects are usually symptoms of flawed processes, not necessarily underperforming individuals. The focus shifts from blaming people to understanding, analyzing, and improving the processes they work within. By mapping and refining workflows, you create systems where doing the right thing is easier and errors are less likely.

- Practice Proactive Management:

Instead of constantly reacting to problems after they occur (“firefighting”), Six Sigma encourages proactive management and prioritized risk assessments. This involves setting ambitious goals, anticipating potential issues, using data to identify trends before they become major problems, and implementing preventative measures and controls to sustain improvements.

- Enable Boundary-less Collaboration:

Processes rarely exist in isolation; they often cross departmental or functional boundaries. Six Sigma promotes breaking down these organizational silos. Effective process improvement requires collaboration between different teams (e.g., design, production, sales, service) sharing knowledge and working together towards common quality goals.

- Strive for Perfection, Tolerate Failure:

The goal of “Six Sigma” itself represents a statistical target of near-perfect quality (only 3.4 defects per million opportunities). While absolute perfection might be unattainable, the principle is about relentless continuous improvement – always seeking ways to do better. Importantly, this pursuit includes tolerating and learning from controlled failures during the experimentation and improvement phases (Analyze, Improve). It’s about progress, not paralysis.

Learning how to apply these principles effectively is a key outcome of structured Six Sigma training.

The Heartbeat of Six Sigma: DMAIC & DMADV

At the core of Six Sigma practice are two primary methodologies – structured roadmaps that guide process improvement and design efforts from start to finish. Choosing the right methodology depends on whether you are fixing an existing process or creating a new one.

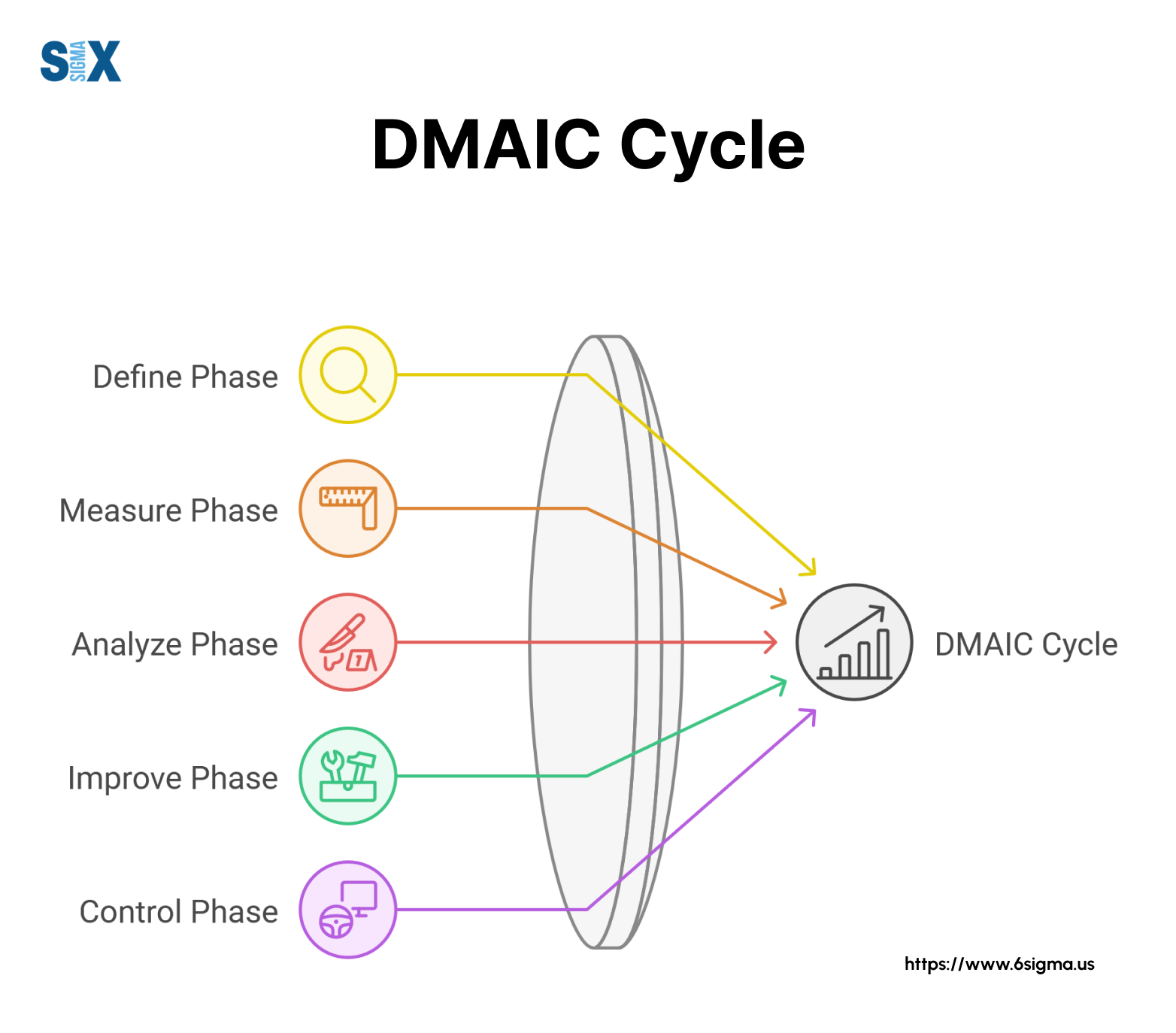

DMAIC: Improving Existing Processes

The most widely recognized Six Sigma methodology is DMAIC, an acronym standing for Define, Measure, Analyze, Improve, and Control.

- Purpose: DMAIC is used to improve existing business processes that are falling short of expectations or desired performance levels.

Here’s a brief look at each phase:

- Define: Clearly identify the problem, the project goals, customer requirements (VOC), the financial impact of the problem and the scope of the project.

- Measure: Collect data to establish baseline performance for the current process. Identify key metrics and develop a data collection plan to ensure timely and accurate data.

- Analyze: Scrutinize the collected data to identify the root cause(s) and largest sources of variation of defects or problems. Break down the data into groups or correlate to input settings to determine why the problem is happening using statistical tools.

- Improve: Develop, test, and implement solutions to address the root causes identified in the Analyze phase. Verify improvements with hypothesis testing.

- Control: Implement measures to sustain the gains achieved by the improvements. Monitor the improved process to ensure performance remains stable and doesn’t regress.

Question: In the DMAIC process, where do projects most commonly get ‘stuck’ or derailed based on your experience, and what’s a key piece of advice for navigating that specific hurdle?

In my experience, projects most commonly get stuck in the Analyze phase. It’s that critical moment where teams need to move from symptoms to root cause — and that’s where the wheels can wobble. Why? Because it demands hard evidence, not assumptions. And a lot of teams are more comfortable jumping straight to solutions.

Anyone who attempts to do a Six Sigma Project should not confuse efficiency with proper analysis. Failure to do this can result in wrong solutions being taken.

This is where impatience shows up. People want to do something — but if you don’t slow down and prove what’s actually causing the problem, you’re just putting a Band-Aid on a bullet wound.

My key advice? Don’t shortcut the data. Validate your root causes with facts, not feelings. Use tools like hypothesis testing or regression properly, and don’t be afraid to challenge your own thinking. When you really nail the Analyze phase, the Improve phase practically writes itself — and the solutions stick. Then the Control Phase helps you keep all those improvements in place, until we find a new better way.

– Peter Peterka, Master Black Belt & President, SixSigma.us

Become a certified Lean Six Sigma Green Belt and drive real change in your organization.

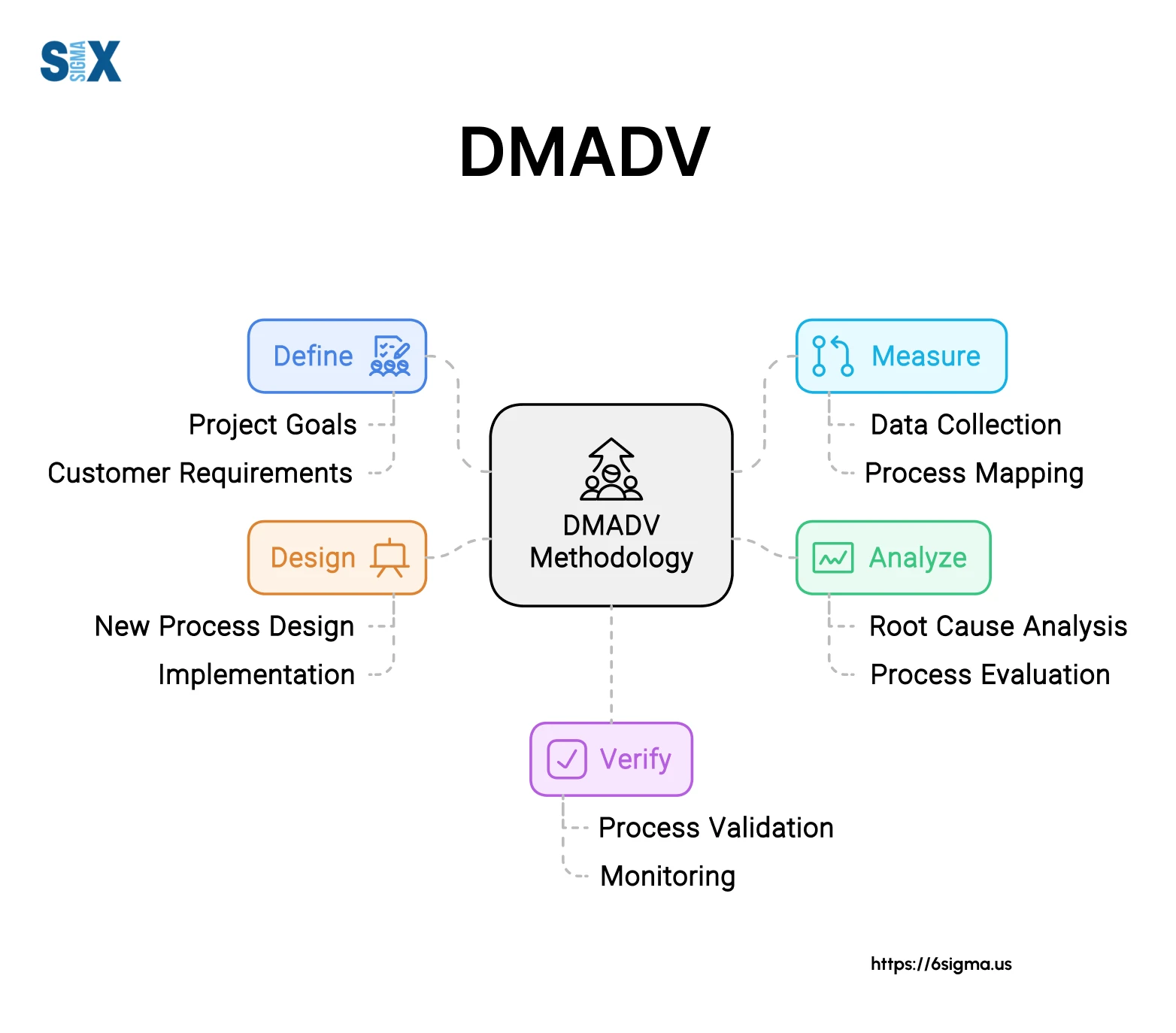

DMADV: Designing New Processes or Products

When the goal isn’t to fix an existing process but to develop a new product or process capable of meeting Six Sigma quality levels from the start, the DMADV methodology is often used. It stands for Define, Measure, Analyze, Design, and Verify.

- Purpose: DMADV is used for designing new processes, products, or services, or for redesigning existing ones when incremental improvement (via DMAIC) is insufficient.

The phases involve:

- Define: Define the project goals and customer deliverables based on customer needs and enterprise strategy.

- Measure: Measure and determine customer needs and specifications; translate VOC into critical-to-quality characteristics (CTQs).

- Analyze: Analyze options to develop and design alternatives. Identify the best approach based on analysis.

- Design: Design the chosen alternative process or product in detail to meet customer needs. Optimize the design.

- Verify: Verify the design performance and its ability to meet customer needs through pilot runs; implement and hand over the new process/product and start delivering to your customers.

When to Use Which? DMAIC vs. DMADV

The distinction is critical:

- Use DMAIC when you have an existing process that needs improvement.

- Use DMADV when you need to design something new or when an existing process requires a complete overhaul rather than just improvement.

Relationship to DFSS (Design for Six Sigma)

DMADV is often considered a core methodology within the broader concept of Design for Six Sigma (DFSS).

DFSS encompasses various tools and approaches (including DMADV, IDOV, etc.) aimed at ensuring that new products or services are designed from the outset to meet customer requirements and achieve Six Sigma quality levels, preventing problems before they start.

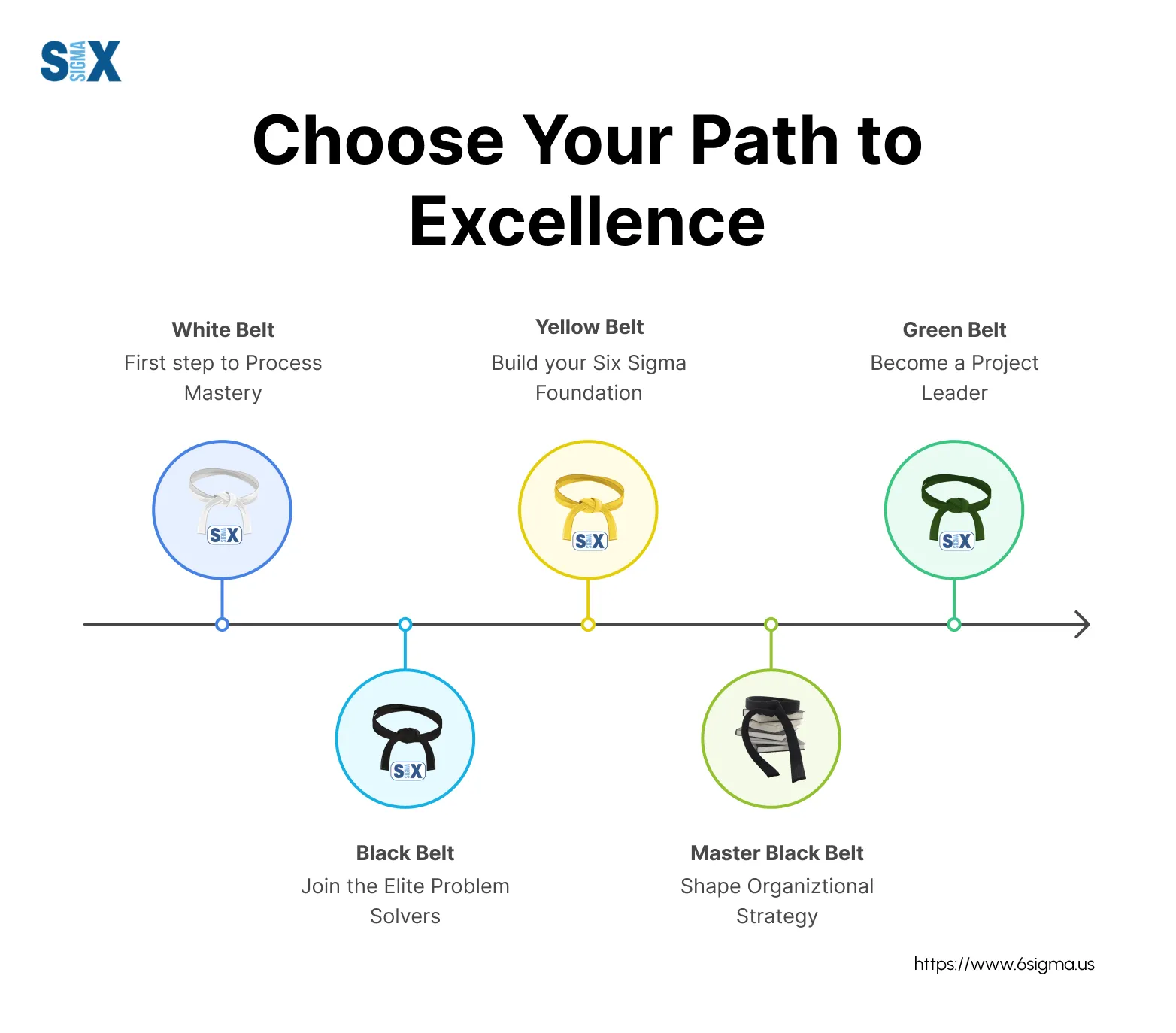

Six Sigma Belts & Certification Levels

Similar to the way martial arts use belts to signify increasing levels of skill and expertise, Six Sigma employs a “Belt” system to recognize proficiency in its methodologies and tools.

Each level represents a deeper understanding and greater responsibility in driving process improvement initiatives within an organization.

Here’s a breakdown of the common Six Sigma and Lean proficiency levels offered through 6Sigma.us:

- White Belt: Provides a foundational awareness of Six Sigma and Lean concepts and vocabulary. White Belts understand the basic principles and structure but typically don’t participate directly in project teams. It’s an excellent starting point for anyone wanting a general overview.

- Yellow Belt: Individuals trained at the Yellow Belt level understand the fundamentals of DMAIC and basic Lean tools. They often participate as core team members or subject matter experts on projects led by Green or Black Belts, assisting with data collection and process mapping.

- Green Belt: Six Sigma Green Belts possess a strong understanding of the DMAIC methodology and can lead smaller-scoped improvement projects within their functional areas. They are adept at data collection and analysis using core Six Sigma tools and often work under the guidance of a Black Belt.

- Black Belt: This level signifies advanced expertise. Six Sigma Black Belts are typically full-time change agents who lead complex, cross-functional improvement projects. They possess a deep understanding of statistical analysis, project management, and team leadership, and they mentor Green Belts.

- Master Black Belt: The pinnacle of the technical Six Sigma path. Master Black Belts train and mentor Black Belts and Green Belts, advise senior leadership on strategic deployment, manage project portfolios, and ensure the overall consistency and quality of the Six Sigma program within an organization.

Explore Six Sigma Certification Programs

- Build a solid Six Sigma foundation

- Hands-on learning with examples

- Taught by industry veterans

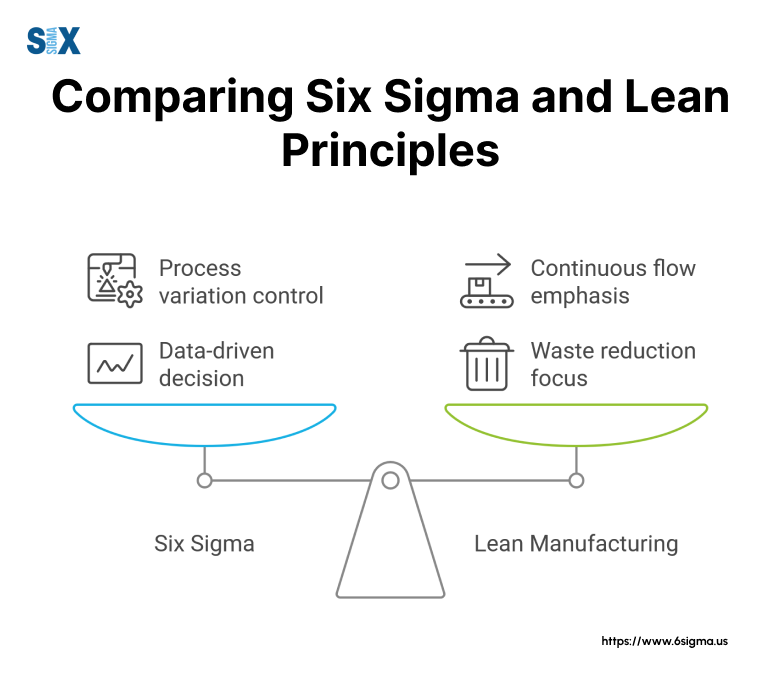

Six Sigma vs. Lean vs. Lean Six Sigma

In the world of process improvement, you’ll often hear the terms Lean, Six Sigma, and Lean Six Sigma used.

While related and often complementary, they represent distinct approaches with different primary focuses. Understanding the differences helps you leverage the right methodology for your specific challenges.

What is Lean?

Lean thinking primarily focuses on maximizing customer value while minimizing waste. Originating from the Toyota Production System, its core goal is to improve process flow and efficiency by systematically identifying and eliminating activities that don’t add value from the customer’s perspective.

Key Lean principles often include:

- Identifying Value: Clearly define what the customer values.

- Mapping the Value Stream: Visualize the entire process flow required to deliver that value, identifying waste.

- Creating Flow: Ensure work moves smoothly through the process without interruptions or delays.

- Establishing Pull: Let customer demand pull work through the process, rather than pushing inventory or tasks forward.

- Seeking Perfection: Continuously strive to improve the process by eliminating waste and refining flow.

Lean excels at: Reducing cycle times, decreasing inventory, improving productivity, and eliminating the “eight wastes” (e.g., defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, extra-processing).

Lean Focused Programs

Recognizing the power of Lean principles, 6Sigma.us also offers specialized Lean training:

- Lean Introduction: Similar to the White Belt, this provides a basic understanding of Lean principles, focusing on identifying the core types of waste (Muda) and the concept of value streams.

- Lean Fundamentals: This program equips participants with the practical knowledge and tools to implement Lean principles effectively. It likely covers key techniques like Value Stream Mapping (VSM), 5S, Kaizen events, etc. to eliminate waste and improve flow. This level often aligns with roles actively participating in Lean initiatives.

- Lean Master: Representing advanced Lean expertise, Lean Masters typically lead significant Lean transformation efforts, design value streams, mentor teams, and drive a culture of continuous improvement focused on flow and waste elimination across the enterprise.

Implement Lean Thinking with Our Lean Certification Programs.

What is Six Sigma?

Six Sigma is a rigorous, data-driven methodology focused on achieving near-perfect quality by minimizing defect reduction and process variation. It uses statistical tools and the DMAIC (or DMADV) framework to identify root causes of errors and implement sustainable solutions.

Six Sigma excels at: Solving complex problems with unknown causes, reducing defects and errors, improving process predictability and consistency, and making data-driven decisions to enhance quality.

What is Lean Six Sigma?

Lean Six Sigma integrates the strengths of both methodologies into a unified approach. It recognizes that processes need to be both efficient (Lean’s focus) and effective (Six Sigma’s focus).

Why do they work so well together?

- Lean identifies waste and speeds up processes: It helps streamline workflows and eliminate non-value-added steps, making processes faster and more efficient.

- Six Sigma improves accuracy and reduces defects within those faster processes: It provides the statistical tools to tackle complex root causes of errors and variation that Lean alone might not address, ensuring the streamlined process is also highly reliable and produces quality outcomes.

Essentially, Lean ensures you are doing things fast, while Six Sigma ensures you are doing things right. Lean Six Sigma provides a comprehensive toolkit to tackle virtually any process challenge, driving significant improvements in speed, quality, cost, and customer satisfaction.

Lead Improvement Projects with Our Lean Six Sigma Certification Programs.

Six Sigma’s power lies not just in its structured methodologies but also in the diverse toolkit it employs to analyze processes, identify root causes, and implement effective solutions.

While mastering these tools often requires dedicated training, understanding the types of tools used, and their purpose is crucial.

These tools aren’t used randomly; they are strategically selected and applied during specific phases of the DMAIC or DMADV frameworks to ensure a data-driven approach to process improvement. Think of them as the instruments a skilled practitioner uses to diagnose and fix process issues.

Here’s a brief overview categorized by common application areas:

- Process Mapping & Understanding: Tools to visualize and understand how a process currently works.

- Process Mapping (Flowcharts): Visually depicts the sequence of steps, decision points, and flow within a process. Essential in the Define and Measure phases to understand the current state.

- Value Stream Mapping (VSM): A Lean tool often used in Lean Six Sigma to map both material and information flow, highlighting areas of waste and delay.

- Data Collection & Measurement: Tools to gather objective information about process performance.

- Check Sheets: Simple, structured forms for collecting and tallying data frequency in real-time. Used heavily in the Measure phase.

- Measurement Systems Analysis (MSA/Gage R&R): Ensures that your measurement methods are accurate and reliable before you start analyzing data. Critical during the Measure phase.

- Root Cause Analysis: Tools to dig beneath the surface symptoms and find the underlying causes of problems.

- Brainstorming: Generates a wide range of ideas about potential causes or solutions. Often used in Analyze and Improve phases.

- 5 Whys: A simple but powerful technique of repeatedly asking “Why?” to drill down to the root cause of an issue. Key in the Analyze phase.

- Fishbone (Ishikawa) Diagram: A visual tool (shaped like a fish skeleton) used to brainstorm and categorize potential causes contributing to a specific effect (problem). A staple of the Analyze phase.

- Data Analysis & Statistical Tools: Tools to interpret data, identify patterns, test hypotheses, and verify improvements.

- Pareto Chart: A bar chart showing frequency of issues in descending order, combined with a line graph showing cumulative percentage. Helps identify the “vital few” causes responsible for most problems (80/20 rule). Widely used in Measure and Analyze phases.

- Histogram: A bar graph showing the distribution or frequency of data points within specific ranges. Helps visualize the spread and central tendency of data. Used in Measure and Analyze phases.

- Control Charts (SPC – Statistical Process Control): Time-based graphs used to monitor process performance, distinguish between common cause and special cause variation, and determine if a process is stable. Essential in the Control phase to sustain gains.

- Failure Modes and Effects Analysis (FMEA): A systematic, proactive method for evaluating a process to identify where and how it might fail and to assess the relative impact of different failures. Often used in Improve or Design phases.

- Hypothesis Testing: A statistical approach to identify significant factors and variables that are causing the problem. Popular techniques include t tests, ANOVA, Regression and Design of Experiments (DOE).

The key is knowing which tool to use, when to use it within the DMAIC/DMADV framework, and how to interpret the results correctly – skills developed through comprehensive Six Sigma training.

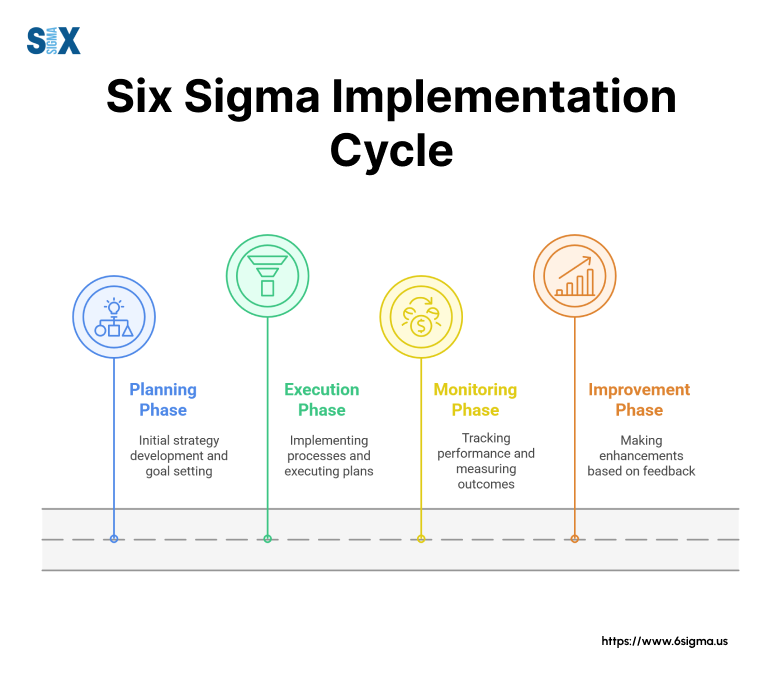

Implementing Six Sigma: Factors & Challenges

Successfully embedding Six Sigma within an organization goes beyond just training individuals; it requires careful planning, sustained effort, and addressing potential roadblocks head-on.

Understanding the key drivers of success and anticipating common challenges can significantly increase the likelihood of achieving lasting process improvement and cultural change.

Key Factors for Successful Six Sigma Implementation:

- Strong Leadership Commitment: This is arguably the most critical factor. Success requires visible, unwavering support from senior management. Leaders must champion the initiative, allocate necessary resources, set clear expectations, and actively participate in reviews. Without this top-down commitment, efforts often stall.

- Clear Communication & Vision: Why is the organization implementing Six Sigma? What are the goals? How will it benefit employees and the company? A clear, consistently communicated vision helps build buy-in, manage expectations, and align everyone towards common objectives.

- Proper Training & Skill Development: Employees at all levels involved need the right training for their roles (from White Belt awareness to Black Belt project leadership). Investing in high-quality, practical training, like that offered by 6Sigma.us, equips teams with the necessary skills and confidence to apply the methodology effectively.

- Choosing the Right Projects: Not all problems are suitable for a Six Sigma project. Successful implementations focus on projects that are strategically aligned, have clear objectives, address significant pain points (for the business or customer), have measurable outcomes, and are achievable within a reasonable time frame. Effective project selection is key.

- Celebrating Wins & Recognizing Efforts: Acknowledge and celebrate both small wins and major project successes. Recognizing the hard work of teams and individuals reinforces positive behaviors, maintains momentum, changes the culture, and demonstrates the financial value of the Six Sigma initiative throughout the organization.

Common Challenges in Six Sigma Implementation:

- Resistance to Change: People naturally resist changes to established routines. Employees may be skeptical, fear job losses, or feel overwhelmed by new methods. Effective change management, communication, and demonstrating ‘What’s In It For Me’ (WIIFM) are crucial to overcome this.

- Lack of Resources (Time & Budget): Six Sigma projects require dedicated time from team members and often budget for training, tools, or implementing solutions. If resources aren’t adequately allocated or protected, projects can flounder. Leadership commitment (see Factor #1) is vital here.

- Data Availability & Quality Issues: Six Sigma is data-driven. Sometimes, the necessary data isn’t being collected, is difficult to access, or is unreliable. Addressing measurement systems and data infrastructure can be a significant early hurdle.

- Scope Creep: Projects that start with a clear focus can sometimes expand uncontrollably, trying to solve too many problems at once. This ‘scope creep’ dilutes effort, delays results, and can lead to project failure. Rigorous adherence to the project charter (Define phase) helps prevent this.

Anticipating these factors and challenges allows organizations to plan proactively, ensuring their Six Sigma implementation delivers the intended results and fosters a sustainable culture of continuous improvement.

Question: Reflecting on successful projects, what’s a specific instance where the team had to adapt the ‘standard’ Six Sigma approach significantly to fit the unique context of their problem, and what was the lesson learned?

One project that really stands out was in a service environment — a contact center dealing with a high volume of complaints about delayed issue resolution. We started with the standard DMAIC approach, but early on it was clear: the process maps and data collection methods just weren’t capturing the real pain points. Everything looked fine on paper — but customers were still frustrated.

So we pivoted. Instead of sticking rigidly to traditional tools, we embedded ourselves in the front lines (The ‘Gemba’ – Japanese word for the Real Place). We sat with agents, listened to calls, mapped the journey of both the employee and the customer. What we discovered was that the delay wasn’t in the process steps — it was in the handoffs, where accountability disappeared. No one ‘owned’ the issue after it escalated.

We adapted by adding Lean-style value stream thinking and layered in service design principles to truly understand the customer experience. We even redefined our Goals based on the customer’s reactions.

The result?

Resolution time dropped by 40%, complaint volume fell significantly, and — maybe most importantly — employee engagement improved because they finally felt empowered to solve problems.

The big lesson: Six Sigma gives you structure, but the real skill is knowing when to adapt it to fit the context. The framework is a guide — the thinking is what creates the breakthrough.

– David Leiva, Master Black Belt, SixSigma.us

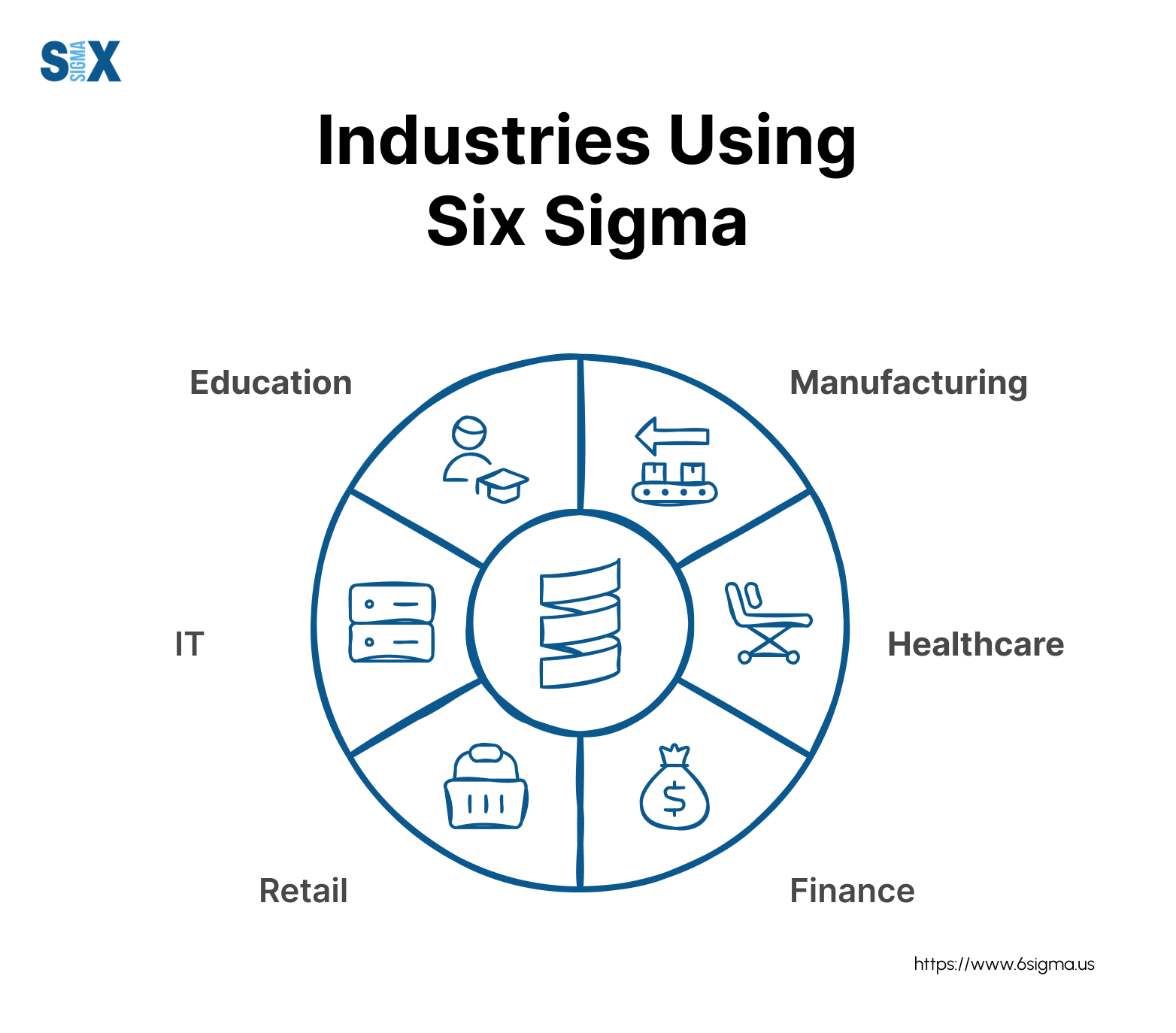

Six Sigma Across Industries: Where is it Applied?

While Six Sigma originated in manufacturing, its principles and data-driven approach have proven remarkably versatile and valuable across nearly every sector.

Organizations worldwide leverage Six Sigma to tackle challenges related to quality, efficiency, cost, and customer satisfaction, regardless of the industry. Let’s look at few industries where Six Sigma makes a significant impact:

- Manufacturing: Its birthplace, used extensively to reduce defects in production lines, optimize supply chains, minimize scrap, and improve product reliability.

- Example: Reducing variations in a parts machining process to decrease rejects and material waste.

- Healthcare: Applied to improve patient safety, reduce wait times, streamline administrative processes (like billing or admissions), and optimize resource utilization in hospitals and clinics.

- Example: Shortening the time it takes for lab results to reach physicians, enabling faster diagnoses and treatment.

- Finance & Banking: Used to reduce errors in financial transactions, improve loan application processing times, enhance customer service accuracy, and ensure regulatory compliance.

- Example: Decreasing errors in account reconciliation processes to improve accuracy and reduce costly investigations.

- Service Industries (e.g., Call Centers, Hospitality, Retail): Implemented to improve customer interaction quality, reduce call handle times, optimize staffing levels, streamline reservation or checkout processes, and enhance overall customer experience.

- Example: Analyzing call center data to reduce dropped calls and improve first-call resolution rates.

- IT & Software Development: Utilized to reduce software defects (bugs), improve project delivery timelines, enhance system reliability and uptime, and streamline IT support processes.

- Example: Applying DFSS principles to design software with fewer inherent flaws, reducing debugging time later.

- Government: Employed by various agencies to improve the efficiency of public services, reduce administrative burdens and wait times, optimize resource allocation, and enhance constituent satisfaction.

- Example: Streamlining the process for issuing permits or licenses to reduce backlog and improve service speed for citizens.

The fundamental goal of reducing variation and eliminating defects through data-driven decisions holds true regardless of the specific “product” or “service” being delivered.

This adaptability is why Six Sigma skills are transferable and highly valued across such a diverse range of professional fields.

Getting Started with Six Sigma

You’ve seen how Six Sigma principles drive powerful improvements across industries and offer significant career advantages. But understanding the concepts is just the first step.

To truly leverage this methodology, gain practical skills, and achieve recognized proficiency, formal training and certification are essential. Investing in your Six Sigma education is investing in your ability to deliver tangible results and advance professionally.

Why Choose 6sigma.us for Your Six Sigma Journey?

When selecting a training provider, you want a partner committed to your success. At 6sigma.us, we don’t just teach theory; we equip you with practical, real-world skills. Here’s why professionals and leading organizations consistently choose us:

- Experienced Instructors: Learn from seasoned Master Black Belts who bring years of hands-on, multi-industry experience directly into the classroom. They don’t just know Six Sigma; they’ve lived it.

- Practical, Hands-On Approach: Our courses emphasize application. Through real-world examples, simulations, and project work, you’ll learn how to use Six Sigma tools effectively, not just memorize definitions.

- Recognized Accreditation: 6sigma.us is proud to be accredited by the International Association for Continuing Education and Training (IACET) and a Registered Education Provider (R.E.P.). This ensures our programs meet rigorous international standards for quality education.

- Flexible Course Formats: We understand busy professionals. Choose the learning style that fits your life, including immersive classroom training, interactive live virtual instructor-led sessions, or flexible online self-paced programs.

- Proven Success Rates: Our focus on practical application and student support translates into high success rates for certification and tangible project results for our graduates and corporate clients.

- Comprehensive Resources: Benefit from high-quality course materials refined and enhanced every few years, project templates, post-course support, and a network of experienced professionals.

Learn More About Our Six Sigma Training Courses

All Courses at 6Sigma.us

- Six Sigma Champion Implementation – Consists of 2 days of onsite training.

- Six Sigma Process Green Belt – Consists of 2 weeks of training either offsite or onsite.

- Six Sigma Process Black Belt – Consists of 2 weeks of Green Belt & 2 weeks of Black Belt after Green Belt either offsite or onsite.

- Six Sigma Transactional Green Belt – Consists of 2 weeks of training either offsite or onsite for those working outside of manufacturing.

- Six Sigma Transactional Process Black Belt – Consists of 2 weeks of Green Belt & 2 weeks of Black Belt after Green Belt either offsite or onsite for those working outside of manufacturing.

- Six Sigma Master Black Belt – Consists of 2 weeks of training either offsite or onsite.

- Design for Six Sigma or DFSS – Consists of 5 days or 10 days of training which is offered at your location or online only.

- Introduction to Minitab for Six Sigma Belts – Consists of ½ day of training offered at your location only.

- Advanced Minitab for trained Six Sigma Belts – Consists of 2 days of training offered at your location only.

To learn more please visit our Course Schedule —>

Additional Programs Available

- Change Management

- Statistical Thinking for Leaders – 2 days

- Business Process Charting – 1 day

- Design of Experiments – 4 days

- Statistical Process Control – 2 days

- Mixture Experimentation – 2 days

- Test Methods – 2 days

Consulting Services for Six Sigma & Lean

6Sigma.us will customize any course to meet our customer’s requirements.

Does this work for healthcare? Yes! In the spring of 2004, one of our Belts within the healthcare industry completed a project that reduced the amount of blood wasted due to expiration. This resulted in Annual Savings of $ 247,876. That is $61,969 worth of savings over 3 months.

Frequently Asked Questions

Q: What is Six Sigma certification?

A: Six Sigma certification validates your expertise in process improvement methodologies and tools, demonstrating your ability to reduce defects and increase efficiency in business processes. It’s a globally recognized qualification that shows your proficiency in applying Six Sigma principles to solve complex business problems.

Q: How to get Six Sigma certification?

A: To obtain a Six Sigma certification, you need to complete the required training, pass an exam, and often complete a project demonstrating your skills. The specific requirements vary depending on the certification level and the certifying body. Our program guides you through each step of the certification process.

Q: Which Six Sigma certification is most recognized?

A: The “best” certification depends on your goals, but Master Black Belt is the highest level, offering:

- Advanced and focused approach to Lean Six Sigma projects

- Statistical methods expertise

- Career growth opportunities

- Leadership and teaching capabilities

Q: Is Six Sigma hard?

A: Six Sigma can be challenging, as it involves learning statistical concepts and tools and applying them into a business setting that requires leadership and team buy-in. However, with dedication, proper training, and practical application, it’s achievable for professionals at all levels.

Our programs are designed to break down complex concepts into manageable modules, making the learning process smoother.

Q: What does Six Sigma focus on?

A: Six Sigma focuses on reducing process variation, eliminating defects, and improving overall quality and efficiency in business processes. It emphasizes data-driven decision-making, customer focus, and continuous improvement to achieve near-perfect quality levels.

Q: How long does it take to get Six Sigma certified?

A: The duration varies depending on the certification level and your prior experience. White and Yellow Belt certifications can be completed in a few days. Green Belt may take 1-2 months for training, and 3-4 months of project completion time. Black Belt certification typically requires 3-4 months of training plus an additional 3-6 months of project completion time.

Q: What are the Six Sigma principles?

A: The core principles of Six Sigma include:

- Focus on the customer

- Identify and understand how the work gets done

- Make processes flow smoothly

- Reduce waste and concentrate on value

- Remove variation and improve predictability

- Involve and equip people in the process

Q: What tools are used in Six Sigma?

A: Six Sigma utilizes various statistical and quality management tools, including:

- Project charter

- Process mapping

- Fishbone diagrams

- Pareto charts

- Capability Analysis

- Measurement System Analysis (Gage R&R)

- Control charts (statistical process control)

- FMEA (Failure Mode and Effects Analysis)

- DOE (Design of Experiments)

- Regression analysis

- Hypothesis Testing

- Control plans

Q: How does Six Sigma differ from other quality management approaches?

A: Six Sigma distinguishes itself through its strong focus on statistical analysis, data-driven decision-making, and achieving measurable financial results. While it incorporates elements from other quality management systems, Six Sigma’s structured DMAIC and DMADV methodologies provide a comprehensive framework for process improvement.

Got More Questions? Talk to Us!

Toll-Free (inside the US): 877 497-4462

International: +1 512 666-9647

Fax: 512 233-2721