Lean Manufacturing Costs: The Guide to Slashing Production Expenses

Companies implementing lean principles report an average 20-30% reduction in operational costs within the first year alone.

That’s not just marginal improvement—it’s transformative change that directly impacts the bottom line.

When manufacturers face mounting pressure to deliver higher quality at lower costs, lean manufacturing emerges as the proven methodology that consistently delivers results.

Ready to transform your manufacturing costs through Lean Six Sigma?

Get started with our industry-leading Lean Six Sigma certification program and learn how to reduce operational costs by 20-30%.

By systematically eliminating waste and optimizing processes, lean approaches tackle manufacturing costs head-on, creating more efficient operations without sacrificing quality.

Rather than viewing cost-cutting as a one-time event, lean establishes a systematic approach to lean introduction that delivers sustained financial benefits.

Key Highlights

- Reduce waste, increase profits

- Optimize workforce productivity effectively

- Lower inventory carrying costs

- Improve quality, reduce rework

What Are Lean Manufacturing Costs?

Understanding lean manufacturing costs requires examining both the investment needed to implement lean principles and the traditional cost structures these methodologies aim to reduce.

Many manufacturing leaders mistakenly focus only on the potential savings without properly accounting for the initial outlays required to transform their operations.

Successful lean implementation delivers significant cost reduction in manufacturing industry, but requires strategic planning and resource allocation.

The financial equation involves balancing short-term investments against long-term operational savings—a calculation that consistently favors companies that commit fully to lean principles.

Initial Investment Costs

The journey toward manufacturing cost reductions begins with several key investments. First, training represents a substantial initial expense.

Teams need proper education in lean methodologies, with costs varying based on training depth and organizational size.

Basic lean awareness training might cost $5,000-$10,000 for a mid-sized company, while comprehensive programs, including six sigma certification programs, can exceed $50,000.

Equipment and technology investments often follow training initiatives. This might include visual management tools, software for tracking metrics, or equipment modifications to support single-piece flow.

Depending on facility size and current technological maturity, these investments typically range from $25,000 to several hundred thousand dollars.

Many organizations also engage external expertise through lean six sigma consultation services. Consultant fees vary widely based on project scope and duration, with rates ranging from $1,500 to $3,500 per day. While expensive, skilled consultants often accelerate implementation and help avoid costly mistakes, ultimately improving ROI.

Documentation systems, measurement tools, and workspace modifications round out the initial investment portfolio.

These costs, while significant, should be viewed as investments rather than expenses—they build the foundation for ongoing cost reduction efforts.

The Three Major Manufacturing Costs

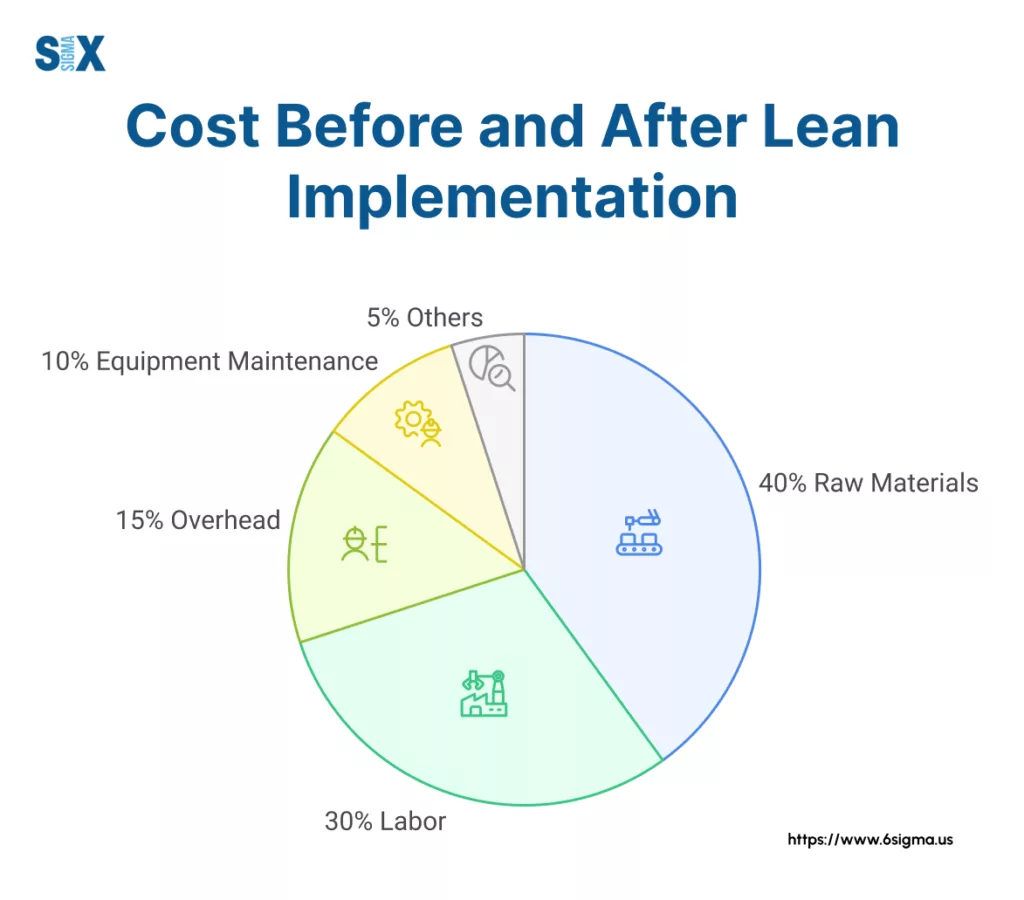

Lean manufacturing directly targets the three primary cost categories that drive manufacturing expenses. Direct materials typically represent 50-70% of product costs in most manufacturing operations.

Lean methodologies reduce these costs through improved yield, scrap reduction, and supplier partnerships that lower raw material prices.

Direct labor, accounting for roughly 10-30% of manufacturing costs, represents the second major expense category.

Lean principles enhance labor productivity by eliminating non-value-added activities, improving workflow, and empowering employees to identify and solve problems. These improvements often allow companies to increase output without adding headcount.

Manufacturing overhead encompasses all other production costs—utilities, maintenance, supervision, depreciation, and facility expenses.

This category typically represents 15-35% of total manufacturing costs. Lean practices reduce overhead through improved space utilization, preventive maintenance programs, and energy efficiency initiatives.

The most successful lean implementations target all three cost categories simultaneously, creating a multiplier effect that dramatically improves overall financial performance.

By addressing these manufacturing cost reductions systematically, companies create sustainable competitive advantages that strengthen their market position.

While the initial investment in lean manufacturing may seem substantial, the long-term cost benefits consistently outweigh these upfront expenses.

Organizations that approach lean as a strategic initiative rather than a tactical cost-cutting exercise achieve the most impressive financial results.

How Lean Manufacturing Reduces Costs

Lean manufacturing costs are dramatically lower than traditional manufacturing approaches because lean methodologies target inefficiencies that drain resources without adding value.

Unlike conventional cost-cutting that often focuses on headcount reduction or supplier squeezing, lean manufacturing creates sustainable efficiency improvements by redesigning processes to eliminate waste.

Eliminating The 8 Wastes

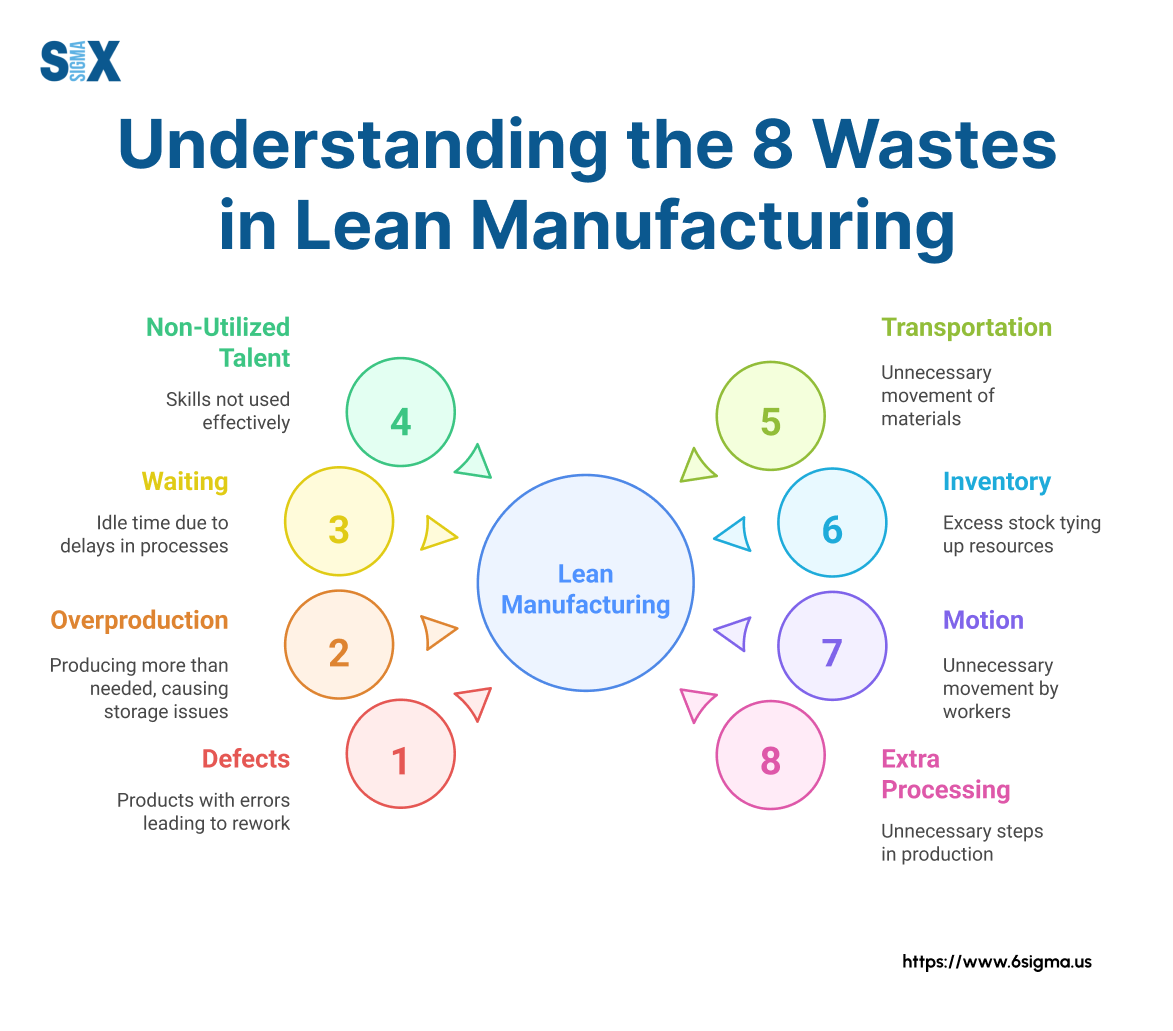

The foundation of reducing manufacturing costs through lean is the elimination of the eight fundamental wastes (sometimes called “DOWNTIME“). Each waste represents a specific type of inefficiency that increases costs without benefiting customers.

Transportation waste occurs whenever products move unnecessarily between processes. Each movement increases handling costs, extends lead times, and risks product damage.

One automotive parts manufacturer reduced transportation waste by re-configuring their plant layout, cutting material movement by 60% and saving $175,000 annually.

Inventory waste ties up capital in raw materials, work-in-process, and finished goods. Excess inventory hides problems and creates storage costs.

A food processor implementing just-in-time principles reduced inventory levels by 40%, freeing up $2.3 million in working capital and cutting storage costs by $340,000 yearly.

Motion waste includes any unnecessary movement by workers. Time studies often reveal that workers spend 30-60% of their time on non-value-added movement.

Ergonomic workstation design and process standardization can reduce this waste, improving productivity while reducing injury risks.

Waiting waste occurs whenever products aren’t being processed. Machine downtime, material shortages, and information delays all create waiting waste. One electronics manufacturer reduced waiting time by 70% through improved scheduling and maintenance practices, increasing throughput by 25%.

Overproduction—making more than needed or earlier than needed—is considered the worst waste because it triggers all other wastes. Implementing pull systems can reduce overproduction, cutting inventory costs and freeing up capacity.

Over-processing adds unnecessary steps that don’t add customer value. Process mapping often reveals that 40-60% of manufacturing steps don’t contribute to product quality or function. Eliminating these steps reduces labor and equipment costs.

Defects create scrap, rework, and customer dissatisfaction. Quality costs typically consume 15-40% of manufacturing expenses. Implementing error-proofing and process controls can dramatically reduce these costs while improving customer satisfaction.

Underutilized talent—failing to leverage employee knowledge and creativity—represents a massive missed opportunity. Structured problem-solving and employee involvement programs tap this potential, generating cost reduction ideas in manufacturing from those who know the processes best.

Eliminating these wastes provides a structured methodology with lean six sigma consultation and experienced coaches who can accelerate the waste reduction process.

Key Lean Tools For Cost Reduction

Several proven lean tools drive significant manufacturing cost reductions when properly implemented.

5S workplace organization (Sort, Set in order, Shine, Standardize, Sustain) creates efficient, visual workspaces that reduce motion waste and improve productivity.

Kaizen events—focused improvement workshops—tackle specific process problems through rapid, team-based problem-solving.

These events generate quick wins while building employee problem-solving capabilities. A medical device manufacturer conducted monthly kaizen events that delivered average savings of $27,000 per event with minimal capital investment.

Value Stream Mapping visualizes the entire production process, highlighting delays, inventory points, and information flows.

This powerful diagnostic tool typically reveals that less than 10% of total lead time adds customer value.

By targeting non-value activities identified through mapping, companies achieve dramatic lead time and inventory reductions.

Standard Work documents the current best practice for each process, reducing variation and creating a baseline for improvement.

Standardization typically yields 15-25% productivity improvements while reducing training time and quality issues.

Quick Changeover (SMED) techniques reduce setup times, enabling smaller batch sizes without sacrificing efficiency. Companies regularly reduce setup times by 50-90%, cutting inventory requirements and improving responsiveness.

Total Productive Maintenance maximizes equipment effectiveness by preventing breakdowns rather than reacting to them. TPM programs typically improve equipment availability by 15-30% while extending asset life.

Effective implementation of these tools requires thorough root cause analysis to identify underlying problems rather than symptoms.

Turn Waste Elimination into Profit Generation

Learn systematic approaches to identify and eliminate costly manufacturing waste through expert-led training.

Measuring ROI and Cost Savings

The true value of lean manufacturing costs becomes evident when organizations properly measure and quantify their results.

Too often, companies implement lean initiatives without establishing clear financial metrics, making it difficult to demonstrate the return on investment to stakeholders.

Calculating Manufacturing Costs

Accurate cost measurement starts with understanding your current manufacturing cost structure. The basic formula for total manufacturing cost is:

Total Manufacturing Cost = Direct Materials + Direct Labor + Manufacturing Overhead

This formula provides the foundation for tracking improvements, but deeper analysis requires breaking these categories into specific cost elements that lean initiatives can target. For example, direct materials costs should be separated into raw material costs, scrap rates, and yield losses to pinpoint improvement opportunities.

When evaluating manufacturing cost savings ideas, companies should calculate both hard savings (directly measurable cost reductions) and soft savings (productivity improvements, capacity increases).

Hard savings immediately impact financial statements, while soft savings often translate to avoided costs or increased revenue potential.

ROI calculations for lean initiatives follow this basic formula:

ROI = (Net Benefits ÷ Project Costs) × 100%

Net benefits include both cost savings and revenue increases attributable to the lean project. Project costs encompass training, consulting, equipment, and employee time dedicated to the initiative.

Most successful lean projects deliver ROI between 200-600% in the first year alone.

Time-based ROI analysis helps prioritize improvement projects. The payback period—the time required for savings to equal the investment—should typically be less than 12 months for operational improvements and less than 24 months for larger capital projects.

Net Present Value (NPV) calculations provide the most rigorous financial analysis by accounting for the time value of money. This approach is particularly valuable for multi-year lean transformation programs with significant upfront investments.

ROI calculator tool showing inputs (project costs, expected savings) and outputs should be like ROI percentage, payback period, NPV).

Key Performance Indicators

Effective measurement of lean manufacturing costs requires tracking both financial and operational KPIs. Financial metrics directly measure cost impact, while operational metrics serve as leading indicators of future financial performance.

Essential financial metrics include:

- Cost per unit (CPU)

- Contribution margin per unit

- Inventory turns

- Cash-to-cash cycle time

- Return on invested capital (ROIC)

These metrics directly reflect cost savings in manufacturing and should be reported monthly to track progress.

CPU should decline as lean initiatives eliminate waste, while inventory turns should increase as excess inventory is reduced.

Critical operational metrics include:

- Overall Equipment Effectiveness (OEE)

- First Pass Yield (FPY)

- Setup/Changeover Time

- Lead Time

- Floor Space Utilization

OEE measures equipment productivity by combining availability, performance, and quality factors. World-class manufacturers achieve OEE above 85%, compared to industry averages of 60-65%.

Each percentage point improvement in OEE typically yields 0.5-1.0% reduction in unit costs.

Benchmarking these metrics against industry standards helps organizations set appropriate targets. Industry associations, consulting firms, and benchmark databases provide comparative data, though metrics definitions may vary.

When possible, normalize benchmarks to account for differences in product complexity, volume, and regional factors.

Visual management systems should display these metrics prominently in production areas, creating transparency and accountability for performance. Digital dashboards can aggregate data across multiple facilities, providing enterprise-wide visibility into lean manufacturing costs and savings.

Regular review meetings should analyze these metrics, identify gaps, and launch targeted improvement initiatives. The most effective organizations establish a closed-loop process where metrics drive action, and actions improve metrics.

Maximize Your Lean Manufacturing ROI

Get certified in proven methodologies that deliver measurable cost savings and operational excellence.

Implementation Strategy

Successful reduction of lean manufacturing costs requires more than random improvement activities—it demands a structured implementation approach that builds momentum while delivering financial results.

Organizations that achieve the greatest cost benefits follow a deliberate strategy that balances quick wins with long-term capability development.

Step-By-Step Cost Reduction Plan

The journey to reduce manufacturing costs begins with a thorough assessment of current operations. This diagnostic phase identifies the highest-impact improvement opportunities and establishes a baseline for measuring progress.

A value stream assessment typically reveals that 30-60% of activities add no customer value, representing immediate cost-saving opportunities.

During the assessment, cross-functional teams should map key processes, collect baseline metrics, and identify critical cost drivers.

Financial analysis should quantify the cost impact of current inefficiencies, creating urgency for change. This analysis often reveals that how to reduce manufacturing costs isn’t about working harder—it’s about eliminating the waste that consumes resources without adding value.

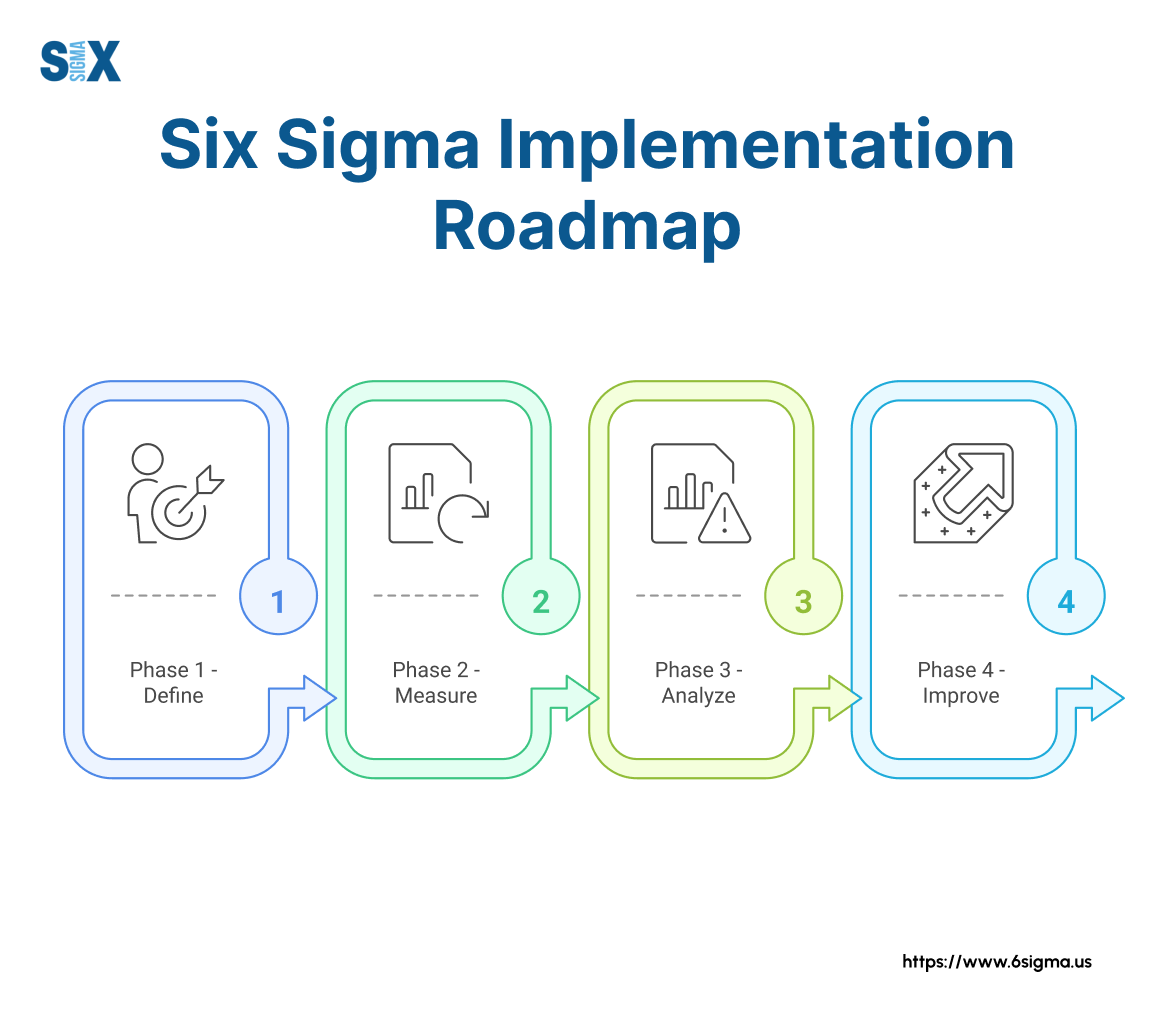

With assessment complete, organizations should develop a phased implementation roadmap. The most effective approach follows this sequence:

Phase 1 focuses on stability

Standardizing work processes, implementing visual management, and establishing basic problem-solving routines. These foundational elements typically deliver 5-10% cost reduction while creating the stability needed for more advanced improvements.

Phase 2 targets flow

Reorganizing production into cells, reducing batch sizes, and implementing pull systems. These changes often reduce lead times by 50-80% while cutting inventory costs by 20-40%. The improved flow also increases capacity utilization, spreading fixed costs across more units.

Phase 3 emphasizes quality

Implementing error-proofing, statistical process control, and total productive maintenance. These tools typically reduce defect rates by 50-90%, eliminating the substantial costs of scrap, rework, and customer returns.

Phase 4 leverages supplier partnerships

Extending lean principles to the supply chain through supplier development and collaborative cost reduction. Organizations typically achieve 5-15% material cost reductions through these efforts while improving delivery performance.

Throughout implementation, leadership must address common challenges that threaten success. Resistance to change often emerges when employees fear job losses from productivity improvements. Transparent communication about how gains will be used—growing the business rather than reducing headcount—helps overcome this resistance.

Resource constraints frequently limit implementation speed. Prioritizing projects based on financial impact and implementation difficulty helps organizations maximize returns from limited resources.

The lean six sigma and profitability connection becomes evident as organizations use data-driven methods to select high-impact projects.

Sustaining improvements presents another common challenge. Many organizations see initial gains erode as old habits return.

Countermeasures include robust management systems, regular audits, and recognition programs that reinforce desired behaviors.

Technology integration often creates implementation hurdles. Legacy systems may not support lean practices like pull production or real-time performance tracking.

Successful organizations align their technology roadmap with their lean strategy, ensuring systems enable rather than impede improvement.

Moving Ahead with Lean Manufacturing Costs

Lean manufacturing costs represent both an investment in future capability and an opportunity for immediate financial improvement.

The principles and methods outlined in this guide provide a roadmap for organizations seeking to enhance their competitive position through operational excellence.

The journey begins with understanding the fundamental cost structure of manufacturing operations and identifying the wastes that inflate these costs unnecessarily.

By systematically eliminating these wastes, organizations can achieve substantial cost reductions while improving quality and customer responsiveness.

Successful implementation requires more than tool application—it demands leadership commitment, cultural change, and disciplined execution.

Organizations that approach lean as a business system rather than a collection of techniques achieve the most impressive and sustainable results.

The financial benefits of lean extend far beyond direct cost reduction. Improved cash flow from inventory reduction, enhanced capacity utilization, and greater operational flexibility create competitive advantages that strengthen market position and support growth.

The most successful manufacturers recognize that lean is not a destination but a continuous journey of improvement.

By embedding lean thinking throughout the organization, these companies create a sustainable competitive advantage that delivers lasting financial results.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs