What is DMEDI? Design for Six Sigma Process Excellence

Companies constantly seek ways to streamline processes, enhance customer satisfaction, and drive innovation.

While the Six Sigma methodology has long been recognized for improving existing processes through the DMAIC (Define, Measure, Analyze, Improve, Control) approach, the DMEDI framework offers a powerful tool for designing and implementing entirely new processes or products.

This methodology, which falls under the umbrella of Design for Six Sigma (DFSS), provides a structured and data-driven approach to creating new processes or products that are tailored to meet customer and business requirements from the outset.

Key Highlights

- Understand the fundamental differences between DMEDI, DMAIC, and DMADV methodologies, and when to apply each approach.

- Gain insights into the five phases of DMEDI: Define, Measure, Explore, Develop, and Implement, and the specific tools and techniques used in each stage.

- Explore practical applications of DMEDI across various industries, including manufacturing, services, healthcare, and life sciences.

- Learn best practices for successful DMEDI project implementation, such as team selection and training, stakeholder engagement, data-driven decision-making, and sustaining continuous improvement.

- Discover the professional development opportunities and certifications available in DMEDI and Design for Six Sigma (DFSS).

This article will explain the intricacies of the DMEDI process, exploring its five distinct phases and the tools and techniques that can be leveraged at each stage.

What is DMEDI?

This structured approach, rooted in the principles of Design for Six Sigma (DFSS), provides a comprehensive framework for designing and implementing new processes, products, or services that are tailored to meet customer and business requirements from the ground up.

Define, Measure, Explore, Develop, and Implement (DMEDI)

The DMEDI methodology consists of five distinct phases: Define, Measure, Explore, Develop, and Implement.

Each phase plays a crucial role in ensuring the successful creation and deployment of a new process or product that meets the highest standards of quality and efficiency.

Define Phase

The Define phase lays the foundation for the entire project. During this stage, we clearly define the problem or opportunity at hand, establish project goals and objectives, identify key stakeholders and customers, and map out the project scope and requirements.

Tools like project charters, SIPOC (Suppliers, Inputs, Processes, Outputs, Customers) diagrams, and voice of the customer (VOC) analyses are invaluable in this phase.

Measure Phase

In the Measure phase, we gather and analyze data to quantify the current state of the process or product under development.

This involves determining critical-to-quality (CTQ) metrics, collecting baseline performance data, and translating customer requirements into measurable design specifications using techniques such as Quality Function Deployment (QFD).

Explore Phase

The Explore phase is where creativity and innovation take center stage. Here, we leverage brainstorming techniques, affinity diagrams, and concept selection tools like the Pugh matrix to generate and evaluate multiple design concepts.

Design of Experiments (DOE) is also employed to identify the critical factors influencing the process or product performance.

Develop Phase

During the Development phase, we refine and optimize the selected design concept, creating detailed specifications and prototypes.

Risk assessment tools like Failure Mode and Effects Analysis (FMEA) are used to identify and mitigate potential risks, while pilot testing and simulations help validate the design before full-scale implementation.

Implement Phase

In the final phase, we implement the new process or product by deploying it in a controlled environment.

This involves developing process control plans, providing training and documentation to stakeholders, and establishing mechanisms for continuous monitoring and improvement.

When to Use DMEDI

The DMEDI methodology is particularly well-suited for scenarios where an organization needs to design and implement entirely new processes, products, or services from scratch.

However, it can also be applied in various other contexts, such as –

Existing Process Improvement (DMAIC)

While DMAIC (Define, Measure, Analyze, Improve, Control) is the go-to approach for improving existing processes, DMEDI can be leveraged when the desired improvements require significant redesign or the creation of new sub-processes.

New Product/Service Development

DMEDI is an ideal choice when an organization wants to develop and launch new products or services that align with customer needs and expectations while adhering to the highest quality standards.

Process Optimization

In scenarios where organizations aim to optimize their processes for enhanced efficiency, cost-effectiveness, or resource utilization, DMEDI can provide a structured framework for redesigning and implementing optimized processes from the ground up.

Root Cause Analysis

When faced with complex or recurring problems, DMEDI can be employed to identify and address the underlying root causes by redesigning the processes or products responsible for these issues.

The Five Phases of DMEDI Explained

The true power of the DMEDI methodology lies in its structured, step-by-step approach to designing and implementing new processes or products.

Each of the five phases – Define, Measure, Explore, Develop, and Implement – serves a distinct purpose and leverages a range of tools and techniques that have been honed through decades of Six Sigma application across diverse industries.

Define Phase

The Define phase is the cornerstone of any successful DMEDI project.

Here, we establish the project’s scope, goals, and objectives, ensuring alignment with the organization’s overall strategy and business priorities.

A well-crafted project charter serves as a roadmap, outlining the problem statement, project boundaries, and measurable success criteria.

Understanding and translating customer needs into actionable requirements is crucial in this phase.

Through Voice of the Customer (VOC) analyses, we gather insights from various stakeholders, including end-users, subject matter experts, and internal customers. These requirements form the foundation upon which the new process or product will be designed.

While customer satisfaction is paramount, we must also consider the organization’s business objectives and constraints.

The Voice of the Business (VOB) analysis helps us identify and prioritize the key drivers, such as cost reduction, increased efficiency, or regulatory compliance, that will shape the design and implementation of the new process or product.

By visualizing the current state and identifying potential bottlenecks or inefficiencies, we can better understand the areas requiring improvement or redesign.

Measure Phase

The Measure phase is all about gathering and analyzing data to establish a baseline understanding of the current process or product performance.

We employ various data collection methods, such as sampling, surveys, or direct observation, to capture relevant metrics and key performance indicators (KPIs).

Not all metrics are created equal. In this phase, we identify the Critical to Quality (CTQ) metrics that directly impact customer satisfaction and process performance.

These CTQs become the focal point for our improvement efforts, ensuring that we prioritize the areas that matter most to our customers and stakeholders.

By establishing a clear baseline of the current process or product performance, we can quantify the gap between the current state and the desired future state.

This baseline serves as a reference point for measuring the effectiveness of our improvement efforts and tracking progress throughout the DMEDI journey.

Quality Function Deployment (QFD) is a powerful tool that helps us translate customer requirements into measurable design specifications.

By creating a “house of quality”, we can prioritize customer needs, identify relationships between requirements and design characteristics, and ensure that our new process or product meets or exceeds customer expectations.

Explore Phase

In the Explore phase, we tap into the collective creativity and expertise of our cross-functional team.

Through structured brainstorming sessions, we generate a diverse range of ideas and potential solutions for addressing the identified challenges or opportunities.

To organize and synthesize the wealth of ideas generated during brainstorming, we employ affinity diagrams.

This powerful tool helps us cluster related ideas, identify patterns and themes, and ultimately distill the most promising concepts for further exploration.

With multiple design concepts on the table, we need a systematic approach to evaluate and select the most viable option(s).

The Pugh matrix, a decision-making tool, allows us to compare the strengths and weaknesses of each concept against a set of predefined criteria, ensuring that our final choice aligns with customer requirements and business objectives.

Design of Experiments (DOE) is a powerful statistical technique that enables us to identify the critical factors influencing the performance of our new process or product.

we can understand the relationships between input variables and output responses, leading to optimized designs that deliver consistent and reliable performance.

Develop Phase

In the development phase, we refine and mature the selected design concept(s) into a detailed, comprehensive plan.

This involves creating detailed specifications, engineering drawings, process flow diagrams, and prototypes, ensuring that every aspect of the design is thoroughly evaluated and optimized.

To achieve the highest levels of performance and efficiency, we leverage various optimization techniques, such as response surface methodology (RSM) and robust design principles.

These tools help us identify the optimal settings for critical process parameters, ensuring that our new process or product is not only high-performing but also resistant to variability and external disturbances.

Proactive risk management is essential in any new endeavor. Through Failure Mode and Effects Analysis (FMEA), we systematically identify potential failure modes, their causes, and their effects on the process or product.

This allows us to implement appropriate risk mitigation strategies and contingency plans, minimizing the likelihood of costly failures or disruptions during implementation.

Before full-scale implementation, we conduct pilot testing or simulations to validate the design and identify any remaining issues or opportunities for improvement.

This controlled testing environment allows us to fine-tune the process or product, gather feedback from stakeholders, and make necessary adjustments before committing substantial resources to the implementation phase.

Implement Phase

As we transition to the implementation phase, we develop comprehensive process control plans to ensure that the new process or product performs as intended in the real-world environment.

These plans outline the monitoring mechanisms, statistical process control (SPC) techniques, and corrective actions necessary to maintain consistent performance and quality over time.

Effective training and clear documentation are essential for successful implementation.

We develop comprehensive training programs to equip our teams and stakeholders with the knowledge and skills required to operate and maintain the new process or product.

With the groundwork laid, we proceed with the full-scale implementation of the new process or product.

This phase involves carefully executing the deployment plan, monitoring performance metrics, and addressing any unforeseen challenges or issues that may arise during the initial rollout.

Through regular process reviews, data analysis, and feedback loops, we ensure that our new process or product continues to meet evolving customer needs and business objectives, fostering a culture of ongoing growth and excellence.

Applications and Case Studies of DMEDI

The versatility of the DMEDI methodology is one of its greatest strengths, allowing organizations across various industries to harness its power for designing and implementing new processes or products.

Manufacturing and Production

In the manufacturing realm, DMEDI has proven invaluable for optimizing product designs and streamlining production processes. One notable project I led at 3M involved redesigning the manufacturing process for a new line of adhesive tapes.

By leveraging DMEDI, we were able to explore innovative material formulations and process parameters through Design of Experiments (DOE), ultimately developing a highly efficient and cost-effective production system that exceeded customer expectations.

Services and Transactions

The applications of DMEDI extend far beyond tangible products. In the service sector, I’ve witnessed its impact in enhancing customer experiences and streamlining transactional processes.

The resulting design not only improved customer wait times and first-call resolution rates but also enabled significant cost savings through increased operational efficiency.

Healthcare and Life Sciences

In the healthcare and life sciences sectors, where quality and safety are paramount, DMEDI has played a crucial role in improving patient outcomes and ensuring regulatory compliance.

One example is a project I led for a major pharmaceutical company, where we redesigned the clinical trial process for a new drug candidate.

By leveraging DMEDI, we optimized patient recruitment strategies, streamlined data collection and analysis protocols, and developed robust quality control measures, ultimately accelerating the drug development timeline while maintaining the highest standards of scientific rigor.

Best Practices for Successful DMEDI Projects

While the DMEDI methodology provides a structured framework, successful implementation requires adhering to best practices that I’ve honed over decades of leading process improvement initiatives.

These practices encompass team selection and training, stakeholder engagement, data-driven decision-making, and sustaining continuous improvement.

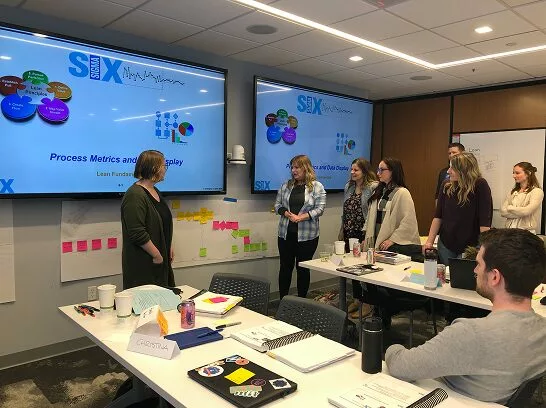

Team Selection and Training

Assembling a cross-functional team with the right mix of skills, expertise, and commitment is crucial for the success of any DMEDI project.

Stakeholder Engagement

Engaging stakeholders early and often is a critical success factor in DMEDI projects. Gaining buy-in from top management not only secures the necessary resources and support but also reinforces the project’s strategic importance.

Data-Driven Decision Making

One of the core tenets of Six Sigma is basing decisions on factual data, rather than assumptions or gut feelings. In DMEDI projects, we leverage a range of statistical analysis tools, such as Minitab or JMP, to ensure that our designs are optimized based on empirical evidence.

Measurement systems analysis plays a crucial role in ensuring the accuracy and reliability of our data, enabling us to make informed decisions with confidence.

Sustaining Gains

While implementing a new process or product is a significant milestone, the journey does not end there. Sustaining the gains achieved through DMEDI requires a commitment to continuous improvement.

We develop detailed control plans, standard work instructions, and monitoring mechanisms to ensure consistent performance over time.

FAQs about DMEDI (Define, Measure, Explore, Develop, and Implement)

The DMEDI process is a structured methodology within the Design for Six Sigma (DFSS) framework, used for designing and implementing new processes, products, or services. It consists of five phases: Define, Measure, Explore, Develop, and Implement.

The five steps in the DMEDI process are:

– Define: Establish project goals, scope, and requirements, and identify customer and business needs.

– Measure: Gather data to quantify current performance and translate customer requirements into measurable design specifications.

– Explore: Generate and evaluate multiple design concepts through brainstorming, affinity diagrams, and concept selection tools.

– Develop: Refine and optimize the selected design concept, conduct risk assessments, and perform pilot testing.

– Implement: Deploy the new process or product, establish control plans, provide training, and enable continuous improvement.

DMAIC (Define, Measure, Analyze, Improve, Control) is a Six Sigma methodology used for improving existing processes, focusing on incremental improvements and defect reduction.

On the other hand, DMEDI is a Design for Six Sigma (DFSS) approach used for designing and implementing entirely new processes, products, or services from scratch, with a focus on innovation and meeting customer and business requirements from the outset.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs