Lean Six Sigma in Operations Management: The Ultimate Guide

Implementing Lean Six Sigma in operations reported reduction in operational costs while simultaneously improving customer satisfaction.

These aren’t just impressive results—they represent a fundamental shift in how leading organizations approach operational excellence.

Transform your career with practical, in-demand skills with Lean Six Sigma Green Belt

Learn from Master Black Belt instructors who’ve helped hundreds succeed

If you’re considering pursuing a six sigma certification to advance your career or improve your organization’s performance, understanding how these principles apply specifically to operations management is your critical first step.

Key Highlights

- Core LSS principles for operations

- Implementation steps for quick wins

- Essential tools for daily application

- Real-world success metrics

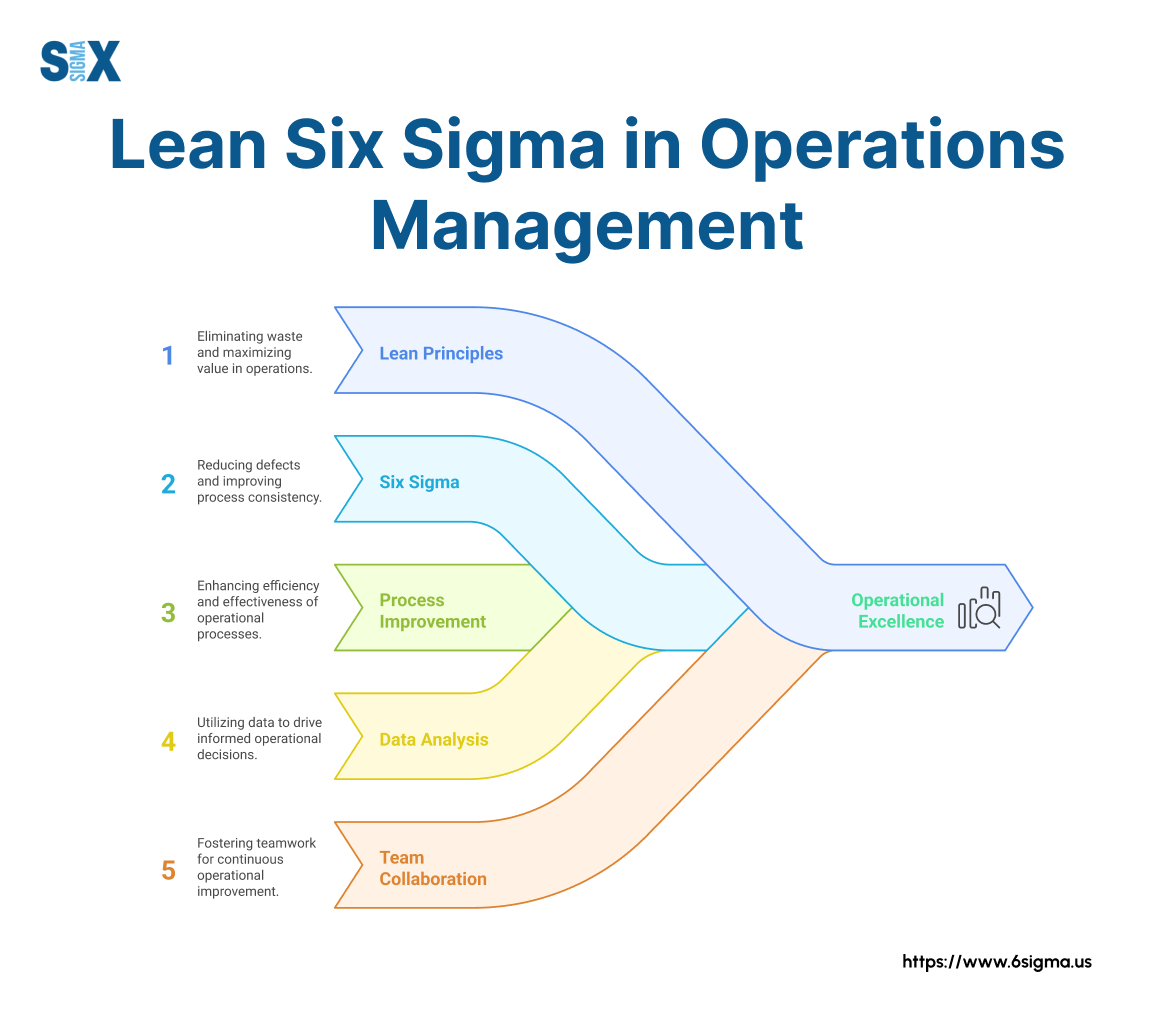

What Is Lean Six Sigma In Operations Management?

Lean Six Sigma in operations management combines two powerful methodologies to create a data-driven approach for eliminating waste and reducing variation in business processes.

Definition and core concepts

This integration merges Lean’s focus on removing non-value-adding activities with Six Sigma’s statistical tools for minimizing defects and inconsistencies.

When applied to operations management, Lean Six Sigma transforms how organizations plan, execute, and control their daily activities. Operations managers use these principles to streamline workflows, reduce bottlenecks, and deliver consistent quality while maintaining cost efficiency.

Evolution and importance

The evolution of this approach traces back to the 1980s when Motorola developed Six Sigma to improve manufacturing quality. Toyota’s Lean production system emerged separately, focusing on waste elimination.

By the late 1990s, forward-thinking companies began combining these methodologies, recognizing their complementary strengths in addressing operational challenges.

What is Six Sigma in operations management specifically? It’s the statistical, data-driven component that helps operations teams reduce process variation to 3.4 defects per million opportunities.

This mathematical precision complements Lean’s practical waste-cutting tools.

Integration of Lean and Six Sigma methodologies

The importance of Six Sigma in operations management cannot be overstated. Organizations implementing these principles typically see 20-30% cost reductions while improving quality metrics.

For operations professionals, mastering these techniques provides both strategic and tactical advantages in managing complex processes.

For those new to these concepts, exploring lean introduction and lean fundamentals resources can provide valuable background knowledge before diving deeper into implementation strategies.

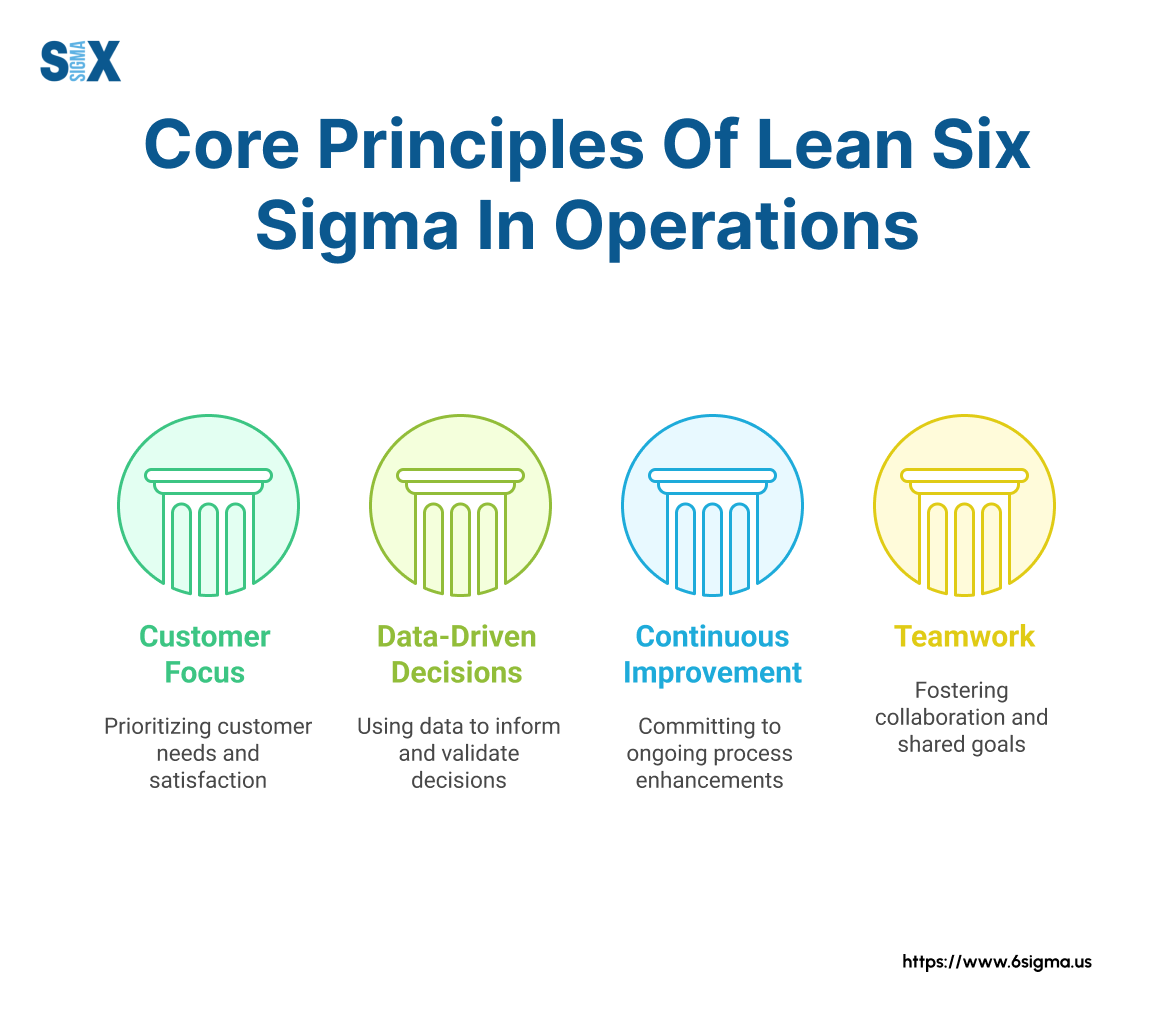

Core Principles Of Lean Six Sigma In Operations

Successful implementation of Lean Six Sigma in operations management relies on understanding and applying its fundamental principles.

These principles guide organizations in eliminating waste, reducing variation, and creating value for customers.

Lean Principles In Operations

The 5S methodology serves as the foundation for Lean operations: Sort, Set in order, Shine, Standardize, and Sustain.

This structured approach creates organized workspaces where inefficiencies become immediately visible.

Manufacturing plants implementing 5S typically report 15-25% productivity improvements within the first three months.

Value Stream Mapping enables operations teams to visualize the entire process flow from raw materials to customer delivery.

This powerful tool identifies bottlenecks, delays, and non-value-adding activities. Operations managers use these maps to target improvement efforts where they’ll have maximum impact.

Just-in-Time Production minimizes inventory costs by producing only what customers need when they need it.

This principle reduces working capital requirements while improving responsiveness to market changes. Companies like Toyota have perfected this approach, maintaining minimal inventory while ensuring product availability.

Six Sigma Principles In Operations

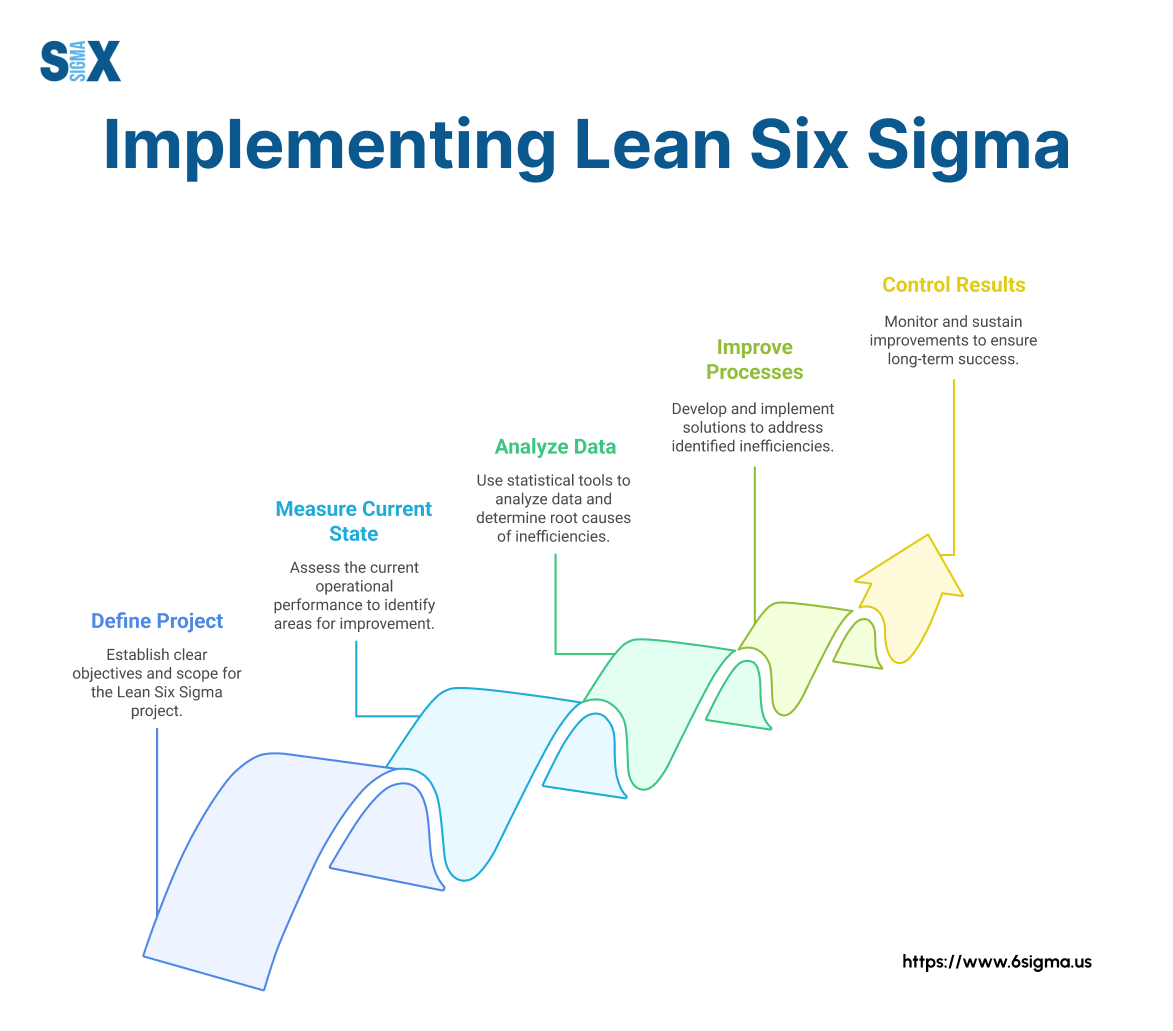

The DMAIC methodology (Define, Measure, Analyze, Improve, Control) provides a structured problem-solving approach for Six Sigma in operations.

This data-driven cycle helps teams tackle complex operational issues systematically rather than jumping to solutions. Each phase builds on the previous one, ensuring thorough analysis before implementation.

Statistical Process Control enables operations teams to monitor process performance using data rather than gut feeling.

By establishing control limits and tracking key metrics, managers can distinguish between normal variation and special causes requiring intervention. This approach prevents overreaction to random fluctuations while highlighting true problems.

Voice of Customer translates customer requirements into measurable operational specifications.

This principle ensures that Six Sigma and operations improvements focus on what truly matters to end users. Organizations that excel at this alignment typically outperform competitors in customer satisfaction metrics.

For complex operational problems, root cause analysis techniques help teams identify underlying issues rather than treating symptoms.

This deeper understanding leads to more effective, sustainable solutions in Lean Six Sigma operations initiatives.

Lead complex improvement projects with confidence

Tackle more complex challenges with our Six Sigma Black Belt Certification to deep dive into advanced analytics and process optimization strategies.

Implementation Framework

Deploying Lean Six Sigma in operations management requires a structured approach that balances quick wins with long-term transformation.

Organizations that rush implementation without proper planning often struggle to sustain initial gains. Conversely, those who spend too much time planning may lose momentum before seeing results.

The right framework provides both immediate benefits and lasting change.

Getting Started With Lean Six Sigma

Assessment and planning form the critical first phase of any successful Lean Six Sigma deployment. This begins with an honest evaluation of current operational performance, identifying pain points and opportunity areas.

Smart organizations establish baseline metrics during this phase, creating a clear “before” picture against which to measure improvements.

Next comes developing a tailored implementation roadmap that reflects your specific operational context.

Manufacturing environments might prioritize defect reduction and equipment effectiveness, while service operations often focus first on cycle time and customer touchpoints.

This customization ensures that Lean Six Sigma in operations management addresses your most pressing challenges.

Team structure and roles determine who will drive the initiative forward.

Most successful programs include:

- Executive sponsors who remove barriers and provide resources

- Project champions who select and prioritize improvement efforts

- Belt-certified practitioners who lead specific projects

The Six Sigma Green Belt certification equips team members with fundamental tools, while Six Sigma Black Belt certification prepares leaders to tackle complex operational challenges.

Organizations typically develop a mix of certification levels to build internal capability.

Project selection criteria represent perhaps the most underappreciated success factor.

The best initial projects demonstrate clear business impact, align with strategic priorities, and can be completed within 3-4 months.

This focused approach builds credibility for Lean Six Sigma in operations management by delivering tangible results quickly.

Tools And Techniques

Essential Lean tools help operations teams identify and eliminate waste. The 5S system organizes workspaces for efficiency, while Kanban visualizes workflow to prevent bottlenecks.

Value Stream Mapping reveals inefficiencies across entire processes, and Standard Work documentation ensures consistency.

These practical tools deliver immediate operational improvements while building momentum for deeper changes.

Critical Six Sigma tools bring statistical rigor to operational problem-solving. Process capability analysis determines if operations can consistently meet customer requirements.

Design of Experiments helps teams optimize process settings efficiently. Measurement System Analysis ensures data reliability—a frequently overlooked but crucial element in Six Sigma in production and operations management.

Integration strategies blend Lean and Six Sigma approaches for maximum impact. Rather than viewing them as separate methodologies, effective programs use Lean tools to identify and eliminate obvious waste, then apply Six Sigma techniques to tackle more complex variation issues.

This combined approach delivers both quick wins and sustainable improvements in operational performance.

Many organizations begin with simple visual management tools that make problems visible, then gradually introduce more sophisticated statistical methods as team capabilities grow.

This progressive implementation builds confidence while developing the analytical skills needed for advanced applications of Lean Six Sigma in operations management.

Common Challenges And Solutions

Even well-planned Lean Six Sigma initiatives face obstacles during implementation. Most organizations encounter similar hurdles when applying these methodologies to operations management.

Understanding these challenges beforehand allows teams to prepare effective countermeasures rather than becoming discouraged when difficulties arise.

Implementation hurdles often begin with resource constraints. Operations teams must balance improvement activities with maintaining daily production or service delivery.

Successful organizations address this by starting with focused projects that don’t overwhelm existing resources.

They also establish clear project scopes with defined timelines to prevent “scope creep” that drains team energy.

Resistance management represents perhaps the most significant challenge in Lean Six Sigma adoption. Employees may view these initiatives as threats to their jobs or criticisms of current practices.

Effective leaders counter this by involving team members in identifying problems and developing solutions.

They emphasize that Lean Six Sigma in operations management aims to make work easier and more satisfying, not just more efficient.

Technical barriers also emerge when teams lack statistical knowledge or improvement experience. Organizations overcome this by providing just-in-time training focused on immediate project needs rather than overwhelming teams with theoretical concepts.

Pairing novice practitioners with experienced mentors accelerates capability development while ensuring project success.

Success factors for sustainable implementation include visible leadership commitment, recognition of early wins, and integration of Lean Six Sigma principles into daily management systems.

Organizations that treat these methodologies as special initiatives separate from normal operations typically see initial gains fade over time.

Your Complete Path to Operational Excellence

Gain internationally recognized certification with Lean Six Sigma Overview.

Conclusion

Lean Six Sigma in operations management offers a powerful approach for organizations seeking to improve quality, reduce costs, and enhance customer satisfaction simultaneously.

By combining Lean’s waste elimination with Six Sigma’s variation reduction, operations teams gain a complete toolkit for tackling their most pressing challenges.

The journey begins with understanding core principles, continues through careful implementation planning, and succeeds through persistent application of appropriate tools and techniques.

Organizations that navigate common challenges while maintaining focus on business results achieve sustainable operational excellence.

Start by identifying one high-impact process improvement opportunity, assemble a cross-functional team, and apply the DMAIC methodology to deliver measurable results.

This initial success will build momentum for broader application of Lean Six Sigma principles throughout your operations.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs