Building a Lean Culture: The Foundation for Lean Six Sigma Excellence

Are your process improvement efforts stalling? You’ve implemented the 5S charts, you hold daily stand-ups, and you’ve mapped out your value streams, but the changes never seem to stick.

The momentum fades, and old habits creep back in. If this sounds familiar, the problem isn’t your tools; it’s the foundation they’re built on.

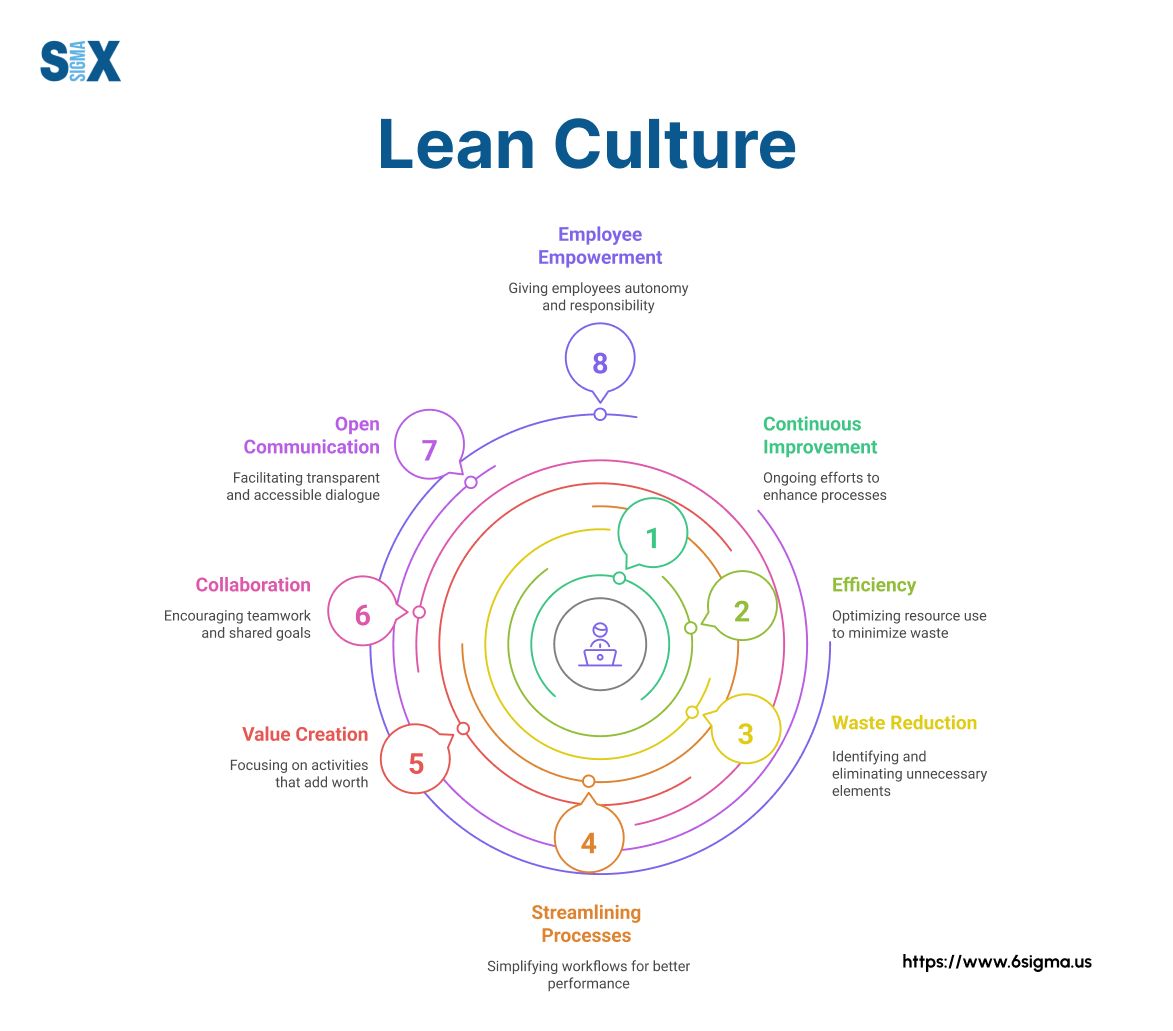

So, what is a lean culture? It’s more than just a project or a set of methodologies. The true lean culture meaning is a shared organizational mindset rooted in two core principles: a relentless pursuit of continuous improvement (kaizen) and a profound respect for people.

This lean culture definition emphasizes a belief system where every single team member is empowered and expected to identify waste and contribute to making the business better, every single day.

Start Your Lean Journey

Before diving into cultural transformation, build a solid foundation with a clear overview of lean principles and terminology.

Think of it this way: if Lean Six Sigma is the powerful software you use to optimize your business, then a lean culture is the essential operating system it runs on.

Lean introduction frames it as the environment needed for success. Without the right OS, even the best software in the world will under-perform or crash because it lacks the right fundamentals of Lean.

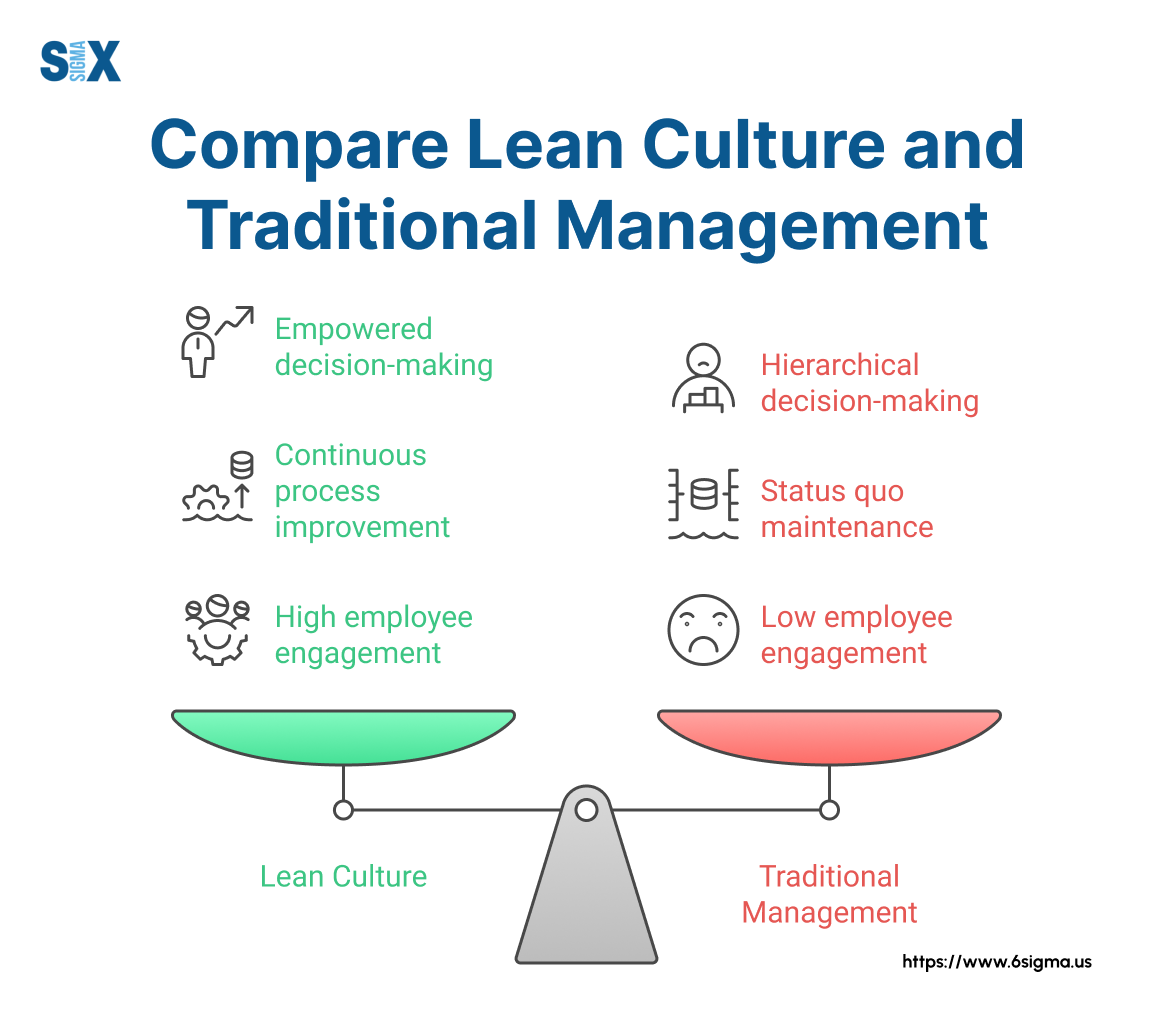

The Unmistakable Difference: Lean Culture vs. Traditional Management

To truly grasp the power of a lean culture, you must first see how it stands in stark contrast to the traditional, top-down management style prevalent in many organizations.

Companies often make the mistake of applying lean tools—like Kanban boards or value stream maps—within a traditional framework, which is like trying to run a modern app on an outdated operating system. The result is almost always friction, frustration, and failure.

The difference isn’t in the tools used, but in the fundamental behaviors and beliefs of the people using them.

This table highlights the core differences:

| Feature | Traditional Management Culture | Lean Culture |

|---|---|---|

| Leadership Style | Command and Control: Leaders dictate solutions and monitor compliance. | Coach and Empower: Leaders ask questions, remove barriers, and develop their people’s skills. |

| Employee Role | Follow Instructions: Employees execute tasks as assigned and escalate problems up the chain. | Solve Problems: Employees are trained and trusted to identify and resolve issues at the source. |

| Problem Solving | Reactive and Blame-Focused: Problems are often addressed only after they become crises, and the focus can be on finding who was at fault. | Proactive and Root-Cause Focused: Problems are seen as opportunities to improve the system. Teams go to the “Gemba” (the actual place where work happens) to understand the issue deeply. |

| Communication | Hierarchical and Need-to-Know: Information flows top-down, and transparency is limited to what is deemed necessary for a specific role. | Transparent and Visual: Information is shared openly. Visual boards and metrics make performance and problems visible to everyone. |

| Primary Focus | Meeting Departmental Targets: Success is often measured by siloed KPIs, which can lead to conflict between departments. | Delivering Customer Value: Success is measured by the end-to-end flow of value to the customer, encouraging cross-functional collaboration. |

It’s also important to distinguish between related concepts. Lean Culture is the overarching umbrella of values and beliefs. The lean management culture refers to the specific systems and leadership behaviors that create and sustain this environment.

Meanwhile, a lean manufacturing culture is the direct application of these principles on the production floor, a vital subset of the overall organizational culture.

Understanding these core distinctions is a critical step in grasping the philosophy.

Master the Core Concepts of the Lean Culture

Go beyond definitions and build a solid understanding of the philosophies and principles that drive effective lean thinking.

The ROI of Culture: Tangible Benefits of a Lean Transformation

Adopting a lean culture is not merely a philosophical exercise; it is a strategic business decision that delivers a powerful and measurable return on investment.

With the right lean six sigma consultation, this transformation is what separates companies that see incremental gains from those that achieve industry-leading performance.

When an organization moves from simply using lean tools to truly living lean principles, the benefits ripple across every facet of the operation.

This lean culture transformation is what separates companies that see incremental gains from those that achieve industry-leading performance.

Here are the tangible benefits you can expect:

Drastically Reduce Systemic Waste

In a traditional setup, waste is often invisible, buried within complex processes and accepted as “the cost of doing business.”

A lean culture trains every employee to see and eliminate the “8 Wastes of Lean“: Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing.

When your entire team is actively working to remove these inefficiencies, you unlock hidden capacity, lower operational costs, and streamline your entire value chain.

Optimize Processes for Superior Quality and Speed

A lean culture is obsessed with improving the flow of value to the customer. By empowering teams on the front lines to solve problems at their source, you dramatically improve quality.

Defects are caught and corrected instantly instead of being passed downstream, which reduces rework and boosts first-pass yield. This focus on process health doesn’t just improve quality; it increases speed.

By eliminating bottlenecks and non-value-added steps, you can deliver products and services to your customers faster than the competition.

Boost Job Satisfaction, Engagement, and Innovation

Perhaps the most profound benefit is the impact on your people. A lean culture replaces micromanagement with empowerment and fear with psychological safety.

When employees are respected, trained, and trusted to improve their own work, their job satisfaction soars. This heightened engagement leads to a more stable, proactive workforce and unlocks a powerful engine for innovation.

The people closest to the work are often the ones with the best ideas for improvement; a lean culture gives them a voice and a mechanism to turn those ideas into reality.

Achieving these benefits is a journey, but the results can be accelerated with expert guidance to ensure you’re focusing on the highest-impact areas first.

Build Your Strategic Roadmap

Translate lean theory into bottom-line results with a clear, data-driven implementation plan tailored to your organization.

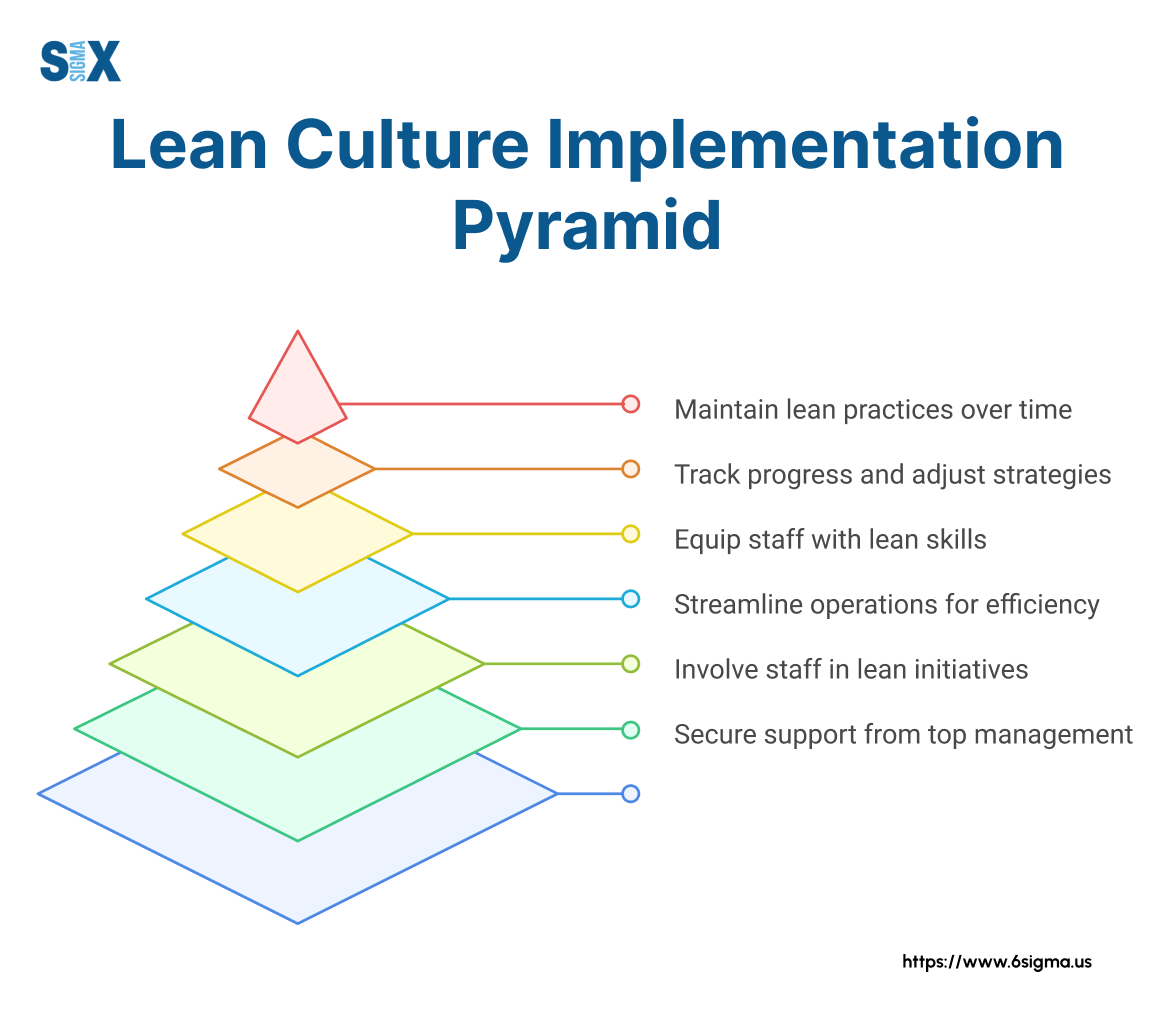

The Blueprint: A 7-Step Guide to Building and Implementing Your Lean Culture

A successful lean transformation doesn’t happen by accident. It requires a deliberate, structured approach that builds momentum and embeds new ways of thinking and working deep within the organization’s DNA.

This section provides the definitive answer to the question, “how to build a lean culture?” by breaking down the process into seven manageable steps.

Following this blueprint for creating a lean culture will provide the structure needed to guide your team from initial concept to a self-sustaining system of continuous improvement.

Step 1: Secure Unwavering Leadership Commitment

This is the non-negotiable first step. A lean culture transformation cannot be delegated from the top; it must be led from the top. Senior leaders must do more than just approve the budget.

They need to actively participate, model the desired behaviors (like going to the Gemba), communicate the vision relentlessly, and align organizational systems (like performance reviews and budgeting) to support the new culture.

Without this visible and unwavering commitment, any progress will be short-lived.

Step 2: Form a Cross-Functional Guiding Team

No single person or department can drive this change alone. Assemble a dedicated guiding team composed of respected individuals from various levels and departments—from the front lines to middle management and executive leadership.

This team will act as the champions and facilitators of the transformation, helping to break down silos, communicate progress, and address resistance across the entire organization.

Step 3: Define Your “True North” and Set Clear Goals

Your organization needs a shared vision of success. What are you trying to achieve? This “True North” should be a simple, powerful statement that connects the lean effort to the organization’s ultimate purpose and strategic objectives.

Is it to achieve perfect quality, deliver on time every time, or create the safest work environment? Once the vision is set, define a handful of key performance indicators (KPIs) that will help you measure progress toward that vision.

Step 4: Train, Empower, and Foster a Learning Environment

You cannot expect people to solve problems if they haven’t been taught how. This is where you create a lean culture at the grassroots level.

Invest in training your employees in the fundamentals of Lean and problem-solving tools. But training is not enough; you must also grant them the autonomy to act.

Empower teams to stop the production line to fix a quality issue, give them time to run improvement experiments, and celebrate learning from failures as much as successes. This creates a psychologically safe environment where people are encouraged to challenge the status quo.

Step 5: Begin with Value Stream Pilots

Instead of attempting a company-wide “big bang” rollout, select one or two critical value streams for focused pilot projects.

This allows the team to practice the new skills in a contained environment, learn from mistakes without disrupting the entire business, and achieve tangible, measurable wins.

These early success stories will build crucial momentum and serve as powerful proof-of-concept to win over skeptics.

Step 6: Standardize Success and Scale the Effort

As the pilot teams refine processes and solve problems, they will develop new best practices. The next step is to standardize this improved work.

This doesn’t mean creating rigid, bureaucratic procedures. It means documenting the best-known way to do the job today, which becomes the new baseline for tomorrow’s improvement.

Once standardized, these successful practices can be scaled and implemented in other parts of the organization, accelerating the transformation.

Step 7: Relentlessly Pursue Continuous Improvement (Kaizen)

The final step is to recognize that there is no final step. A lean culture is not a destination; it’s a perpetual journey. The goal is to embed the cycle of improvement into your daily work.

Leaders must continue to coach, teams must continue to hold improvement events (kaizen), and the organization must regularly reflect on its progress and refine its approach. This commitment to relentless improvement is the engine that will sustain your lean culture for years to come.

In essence, this creating a lean culture summary shows a path from high-level vision to on-the-ground execution. It’s a cycle of learning, doing, and refining that gradually shifts the entire organization’s mindset.

Equipping Your Team for Success: Training as the Engine of Lean Culture

A lean culture is not built on memos or mission statements; it is forged through capability. As highlighted in the blueprint, you must train, empower, and foster a learning environment.

This is the engine of your transformation. Giving your team a shared language and a structured problem-solving toolkit is what turns the abstract concept of “continuous improvement” into a practical, daily reality.

While informal coaching is important, a structured six sigma certification framework ensures consistency and depth of knowledge across the organization.

The Lean Six Sigma belt system provides a proven pathway for developing expertise at every level, ensuring that each employee has the right skills to contribute effectively to the lean culture change.

Here’s how this tiered approach builds capability throughout your organization:

- Foundational Knowledge for Everyone: The journey begins by creating broad awareness. Every single employee, from the front office to the factory floor, can learn to see waste and understand the basic principles of lean.

- Essential Skills for Team Members: For employees who will be active participants in improvement projects, a deeper understanding is needed. They need the skills to use basic lean tools and contribute meaningfully to team efforts.

- Project Leadership for Driving Change: Your culture needs leaders who can guide improvement projects from concept to completion. These individuals require a robust toolkit covering statistical analysis, project management, and team facilitation.

- Full-Time Expertise for Mentoring and Strategy: To truly accelerate and sustain your transformation, you need dedicated internal experts. These professionals serve as mentors, coaches, and strategic leaders for complex, high-impact projects.

- The Pinnacle of Expertise for Program Leadership: At the highest level are the individuals responsible for designing and deploying the entire Lean Six Sigma strategy across the enterprise. They train and mentor the other belts and align the program with top-level business objectives.

Choosing the right development path for your team members is a crucial strategic decision.

Find the Right Training for Every Role

Equip your employees with the exact skills they need to drive your lean transformation, from foundational awareness to expert leadership.

Navigating the Challenges of a Lean Culture Change

Embarking on a lean culture change is a journey filled with incredible opportunities, but it is not without its obstacles. Foreknowledge of these common challenges is the first step to overcoming them.

Successful organizations are not those that avoid problems, but those that anticipate them and have a strategy in place to navigate through them.

Here are some of the most common hurdles you may face and how to address them head-on:

Challenge: Resistance from Middle Management

Often, the strongest resistance doesn’t come from the front lines but from middle managers. They may feel the change threatens their authority or makes their traditional roles obsolete.

They are used to being the primary problem-solvers and directors of work, and the shift to becoming a coach and facilitator can be unsettling.

Solution: Involve them from the very beginning. Make them key members of the guiding team (Step 2 in our blueprint). Reframe their role from “enforcer” to “teacher and coach.”

Their active support is critical, and a lean culture cannot succeed without them championing the cause.

Challenge: Employee Fear and Skepticism of the Lean Culture

Front-line employees may hear “efficiency” and “waste reduction” and immediately think “layoffs.” If they believe that improving a process will eliminate their own job, they will naturally resist the change.

Skepticism can also arise from “flavor-of-the-month” initiatives that were tried and abandoned in the past.

Solution: Communication must be transparent, consistent, and empathetic. Leaders must frame the lean transformation as a growth strategy, not just a cost-cutting one. Explain how increased efficiency will free up capacity to take on new work, innovate new products, or improve service for more customers.

Celebrate early wins publicly and show how improvements have made employees’ work easier and more rewarding, not more precarious.

Challenge: Initial Improvement Efforts Stall or Fail

It’s common for the first few kaizen events or improvement projects to lose steam or fail to deliver the expected results. This can quickly kill momentum and reinforce the belief that “this lean stuff doesn’t work here.”

Solution: This often happens when teams are stuck treating symptoms instead of diagnosing the true illness within a process.

To avoid this, you must insist on a rigorous and structured approach to problem-solving. Equip your teams with robust root cause analysis methods, like the 5 Whys or Fishbone Diagrams, to ensure they dig deep enough to uncover and solve the underlying issue once and for all.

Furthermore, start with small, manageable problems to build the team’s confidence and problem-solving muscle before tackling more complex challenges.

Become an Expert Problem-Solver

Equip your teams with the structured techniques needed to move past treating symptoms and start fixing problems at their source, permanently.

Measuring What Matters: KPIs for a Thriving Lean Culture

In a lean environment, the old adage “what gets measured gets managed” is only half the story.

The full truth is that what gets measured and made visible gets improved by everyone.

Measuring the success of your lean culture isn’t about creating complex reports for management; it’s about providing clear, real-time feedback to the teams doing the work so they can see problems, track their progress, and celebrate their wins.

Effective measurement tells you if your cultural transformation is translating into tangible operational and financial results. Instead of relying on lagging financial-only indicators, a lean culture balances metrics across several key areas.

Here are some essential KPIs to track:

Process Metrics (Measuring Flow)

These KPIs measure the health and efficiency of your core processes.

- Lead Time: The total time it takes for a product or service to go through the entire value stream, from customer order to customer delivery. A consistently decreasing lead time is a primary indicator of improved flow.

- Cycle Time: The time it takes to complete a specific task or one unit of work. Reducing cycle time within processes is a key driver of overall lead time reduction.

- Takt Time: The rate at which you need to complete a product to meet customer demand (e.g., “we need to produce one unit every 5 minutes”). It’s the heartbeat of your operation, and measuring your cycle time against takt time shows if you are meeting demand efficiently.

- First Pass Yield (FPY): The percentage of products or services that are completed correctly the first time, without any need for rework or repair. A high FPY is a direct reflection of quality built into the process.

People Metrics (Measuring Engagement & Empowerment)

These metrics gauge the health of the culture itself.

- Employee Suggestion Rate & Implementation Rate: How many improvement ideas are your employees submitting? More importantly, what percentage of those ideas are being implemented? A high, steady rate is a powerful sign of an engaged and empowered workforce.

- Employee Engagement/Satisfaction Scores: Use regular, simple pulse surveys to track team morale and satisfaction. A thriving lean culture directly leads to a more positive and fulfilling work environment.

- Team-Level Skill Development: Track the number of employees who have been trained (e.g., White Belt, Yellow Belt) and the number of improvement projects (kaizen events) successfully led by teams.

Financial Metrics (Measuring Impact)

These KPIs connect your process and people improvements to the bottom line.

- Cost of Poor Quality (COPQ): This calculates all the costs associated with not doing things right the first time—including scrap, rework, warranty claims, and inspection time. As your lean culture matures, COPQ should steadily decline.

- Throughput: The amount of product or service a value stream can deliver over a period of time. As you eliminate waste and improve flow, throughput should increase without a corresponding increase in resources.

These KPIs should not live in a spreadsheet on a manager’s computer.

They should be displayed prominently on visual management boards where the teams can see them, discuss them in their daily huddles, and use them to decide what problem to tackle next.

An Example of KPI Dashboard

Lean Culture KPI Dashboard

Real-time metrics for continuous improvement and operational excellence

Performance Trends

Lead Time Reduction (Days)

First Pass Yield Improvement (%)

Employee Engagement Metrics

Cost of Poor Quality Reduction ($K)

Make Lean Culture Your Enduring Competitive Advantage

Simply having the best tools or processes is no longer enough. The real, sustainable advantage comes from building an organization that can improve, adapt, and innovate faster than the competition.

As we’ve explored, the foundation for that capability is a genuine lean culture.

Moving beyond just doing lean to truly being lean is what separates companies with temporary gains from those with lasting excellence.

It’s the difference between a few successful projects and a self-sustaining system of continuous improvement that engages every employee, delights every customer, and drives remarkable business results.

This transformation is not a one-time project with a finish line; it is a commitment to a journey of perpetual learning and refinement.

Building this culture is a significant undertaking, but it’s one you don’t have to start alone.

Transform your culture, and you will fundamentally transform your business.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs