The Ultimate Guide to Kata Coaching: Driving Sustainable Improvement in Lean Six Sigma

Let me ask you something: have your Lean Six Sigma project gains ever faded over time? You know the drill. You run a successful project, maybe using DMAIC, hit your targets supported by skills often gained through six sigma certification, document the new standard work, and then… slowly but surely, performance creeps back towards where it was.

This is where we need to look beyond just the DMAIC cycle and think about something deeper – the underlying habits and thinking patterns of our teams. And that’s where kata coaching comes into play.

It’s not just another tool; it’s a structured approach, born from Toyota’s practices, designed specifically to build muscle memory for scientific thinking and continuous adaptation.

What is the Kata Approach in Lean Six Sigma?

The word Kata (型 or 形) itself comes straight from Japanese martial arts. Think karate or judo. It literally means “form” or “pattern.” If you’ve ever seen martial artists practicing, they repeat these precise sequences of movements – these Kata – over and over again.

Why? It’s deliberate practice. The goal isn’t just to learn the moves, but to ingrain them so deeply that they become second nature, almost reflexive, especially under pressure.

Now, how did this get into the world of Lean and business?

The credit largely goes to Mike Rother and his seminal book, “Toyota Kata“. (You can find more on his work here – consider linking to the Toyota Kata website or book reference).

Rother studied Toyota intensely and realized that their sustained success wasn’t just about the visible tools (like Kanban or Andon cords), but about the invisible routines or patterns of thinking and acting that managers and employees practiced daily. He identified these underlying routines and termed them the Toyota Kata.

Kata as a Structured Routine for Developing Scientific Thinking

This brings us to the core of the kata approach in our context. When we talk about Kata in Lean Six Sigma, we’re not talking about a specific chart or a tool you pull out of a box.

Instead, think of it as a structured practice routine or a method designed to help individuals and teams develop and internalize a specific way of thinking – fundamentally, a scientific thinking pattern. It’s the “how” behind continuous improvement.

What kind of thinking? It’s very much aligned with the PDCA (Plan-Do-Check-Act) or PDSA cycle we know well. The kata technique is about deliberately practicing how to:

- Understand the direction or challenge.

- Grasp the current situation factually.

- Define the next specific target to aim for.

And then, crucially, run rapid experiments (PDCA cycles) to learn your way towards that target, especially when the path isn’t clear.

It’s less about having all the answers upfront and more about having a consistent method to navigate uncertainty and learn systematically.

Kata vs. Kaizen: Understanding the Complementary Relationship

Kaizen often refers to improvement activities themselves – maybe a Kaizen event (like a focused workshop) or specific incremental improvements made to a process. You can think of it often as the result or the “what” – what improvement did we make?

Kata, on the other hand, is the structured practice routine used to develop the thinking pattern that enables effective Kaizen and continuous improvement. It’s the underlying “how” – how do we consistently think and act to identify and solve problems and make those improvements?

They aren’t competing ideas; they’re highly complementary. You use the Kata patterns (specifically the Improvement Kata and Coaching Kata, which we’ll detail next) to make your Kaizen efforts more systematic, scientific, and sustainable.

| Feature | Kaizen | Kata |

| Focus | Improvement actions/events; The “What” | Practice routine for thinking; The “How” |

| Nature | Can be event-based or ongoing increments | Daily/Regular structured practice |

| Output | Specific process improvements | Developed skill/habit of scientific thinking |

| Goal | Make improvements | Build capability for continuous improvement |

Understanding this distinction is key. Kata provides the engine, the learned habits, that drive effective and ongoing Kaizen and continuous improvement.

The Twin Engines of Kata Practice: Improvement Kata & Coaching Kata

When we implement kata coaching, we’re actually putting two specific practice routines into motion simultaneously. One is for the person doing the improvement work (the learner), and the other is for the person guiding them (the coach). Let’s break them down.

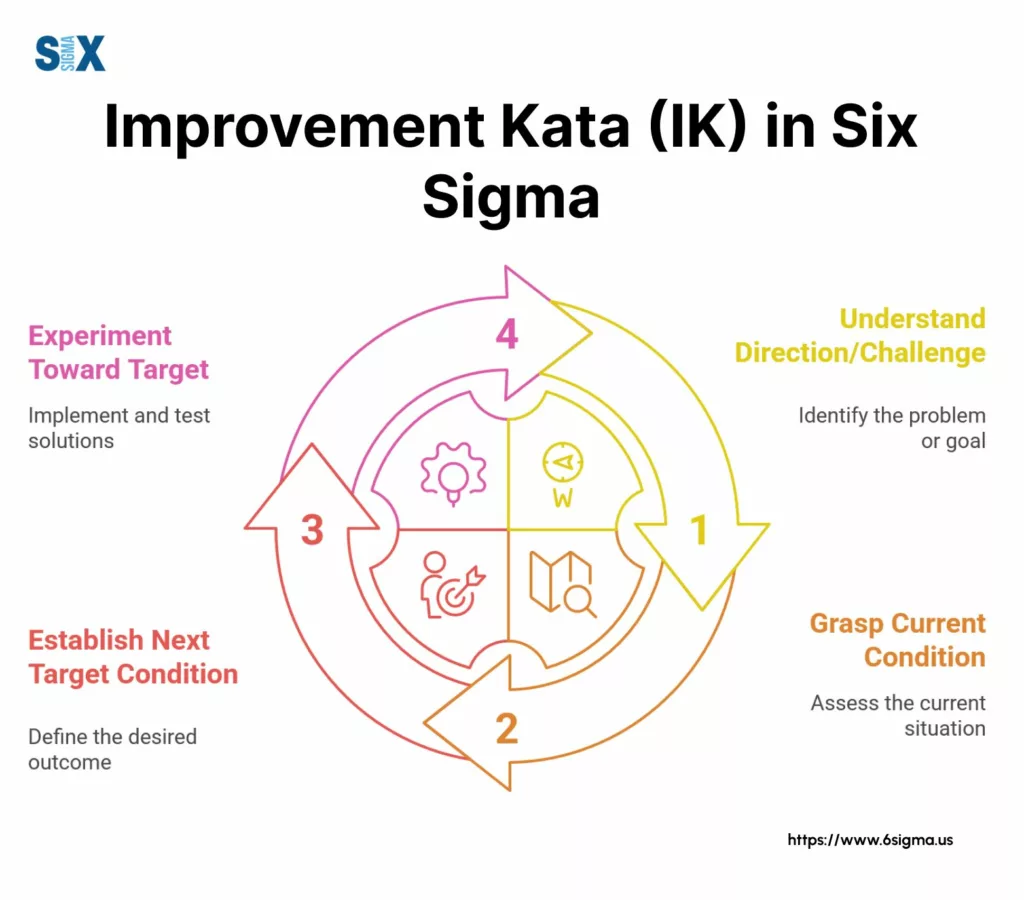

The Improvement Kata (IK): The Learner’s Pattern for Navigating Uncertainty

This is the fundamental, four-step pattern that the learner practices repeatedly to develop their scientific thinking skills and tackle challenges. I like to think of it as their roadmap for navigating the “grey zone” between where they are and where they need to be. The steps are:

- Understand the Direction/Challenge: Get clear on the bigger picture or strategic objective. What overall goal are we striving towards?

- Grasp the Current Condition: Objectively understand the current state of the process related to the challenge. What’s happening now, based on facts and data? This is crucial for defining a meaningful starting point.

- Establish the Next Target Condition: Define a specific, measurable, achievable, relevant, and time-bound (SMART is a good lens here) next milestone on the way to the overall challenge. Where do we want to be, say, next week or in two weeks? This breaks down big challenges into manageable steps.

- Experiment Toward the Target Condition: This is where the rubber meets the road. Conduct rapid PDCA (Plan-Do-Check-Act) cycles to iteratively experiment and learn your way past obstacles that stand between your current condition and your next target condition.

Critically, the Improvement Kata isn’t just a project plan; it’s a practice routine. The learner repeats these steps over and over, applying them to real work, and through that repetition, they build the skill and habit of scientific problem-solving.

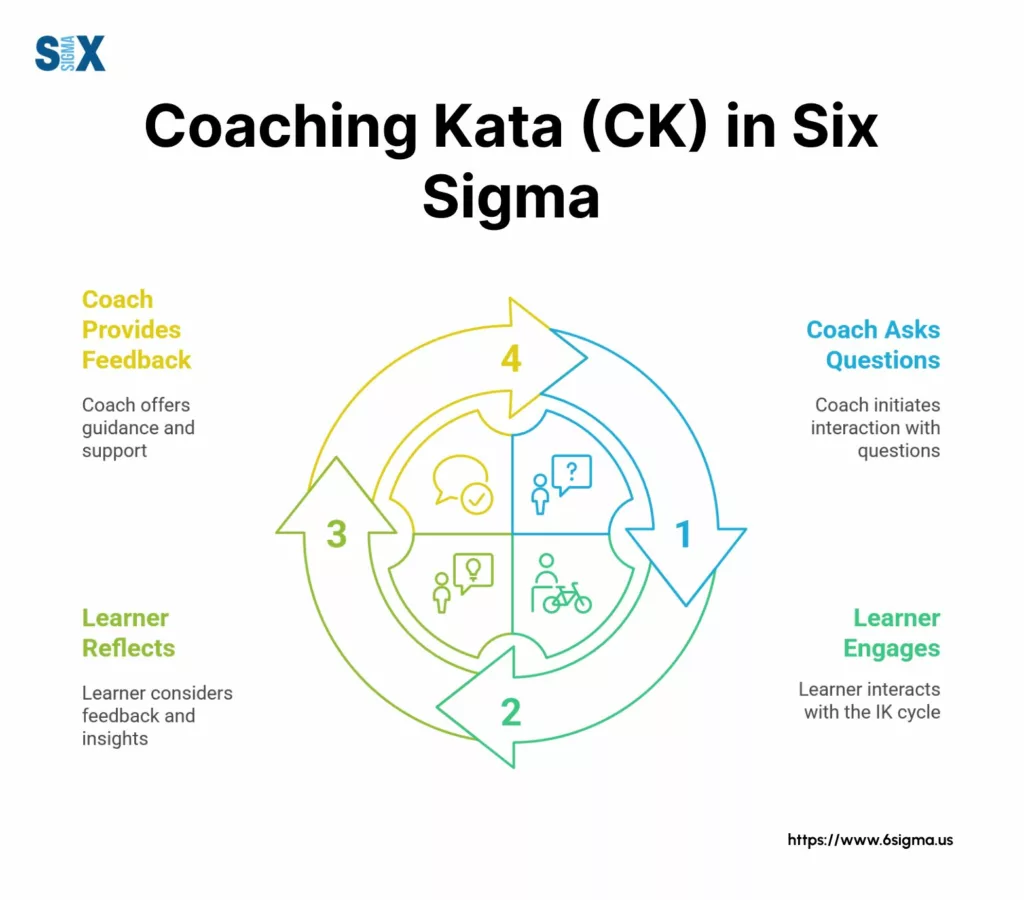

The Coaching Kata (CK): The Manager’s Routine for Developing IK Skills

Now, how does the learner get good at the Improvement Kata? That’s where the second routine, the Coaching Kata (CK), comes in.

This is the pattern practiced by the coach – typically a manager or team leader participating in lean kata coaching, often someone whose project leadership and team guidance skills are honed through training like a six sigma green belt certification. The primary purpose of the Coaching Kata isn’t to solve the learner’s problem or provide solutions.

Instead, the coach kata routine involves asking a specific set of questions (we’ll cover those in detail next) designed purely to guide the learner’s thinking process through the steps of the Improvement Kata.

The coach’s role in toyota kata coaching is to ensure the learner is practicing the IK pattern correctly, thinking scientifically, and learning from their experiments. It’s about developing the learner’s capability.

The Powerful Synergy: How IK and CK Drive Continuous Improvement Together

You can’t really have one without the other for this kata coaching model to work effectively. The Improvement Kata and Coaching Kata routines operate in tandem.

Picture this: the learner is working on their challenge, using the Improvement Kata steps. The coach meets with them regularly – often daily, even if just for 5-10 minutes – right where the work happens.

During these brief coaching cycles, the coach uses the Coaching Kata questions to check in on the learner’s progress through the IK steps:

- What’s your target condition?

- What’s the actual condition now?

- What obstacles are you facing?

- What’s your next step (experiment)?

- What did you learn from your last step?

This dialogue ensures the learner stays on track with the scientific pattern and helps them reflect and learn. It’s this constant, guided practice on real work that builds lasting skills.

It’s about building competence through guided practice. That’s the heart of lean kata coaching.

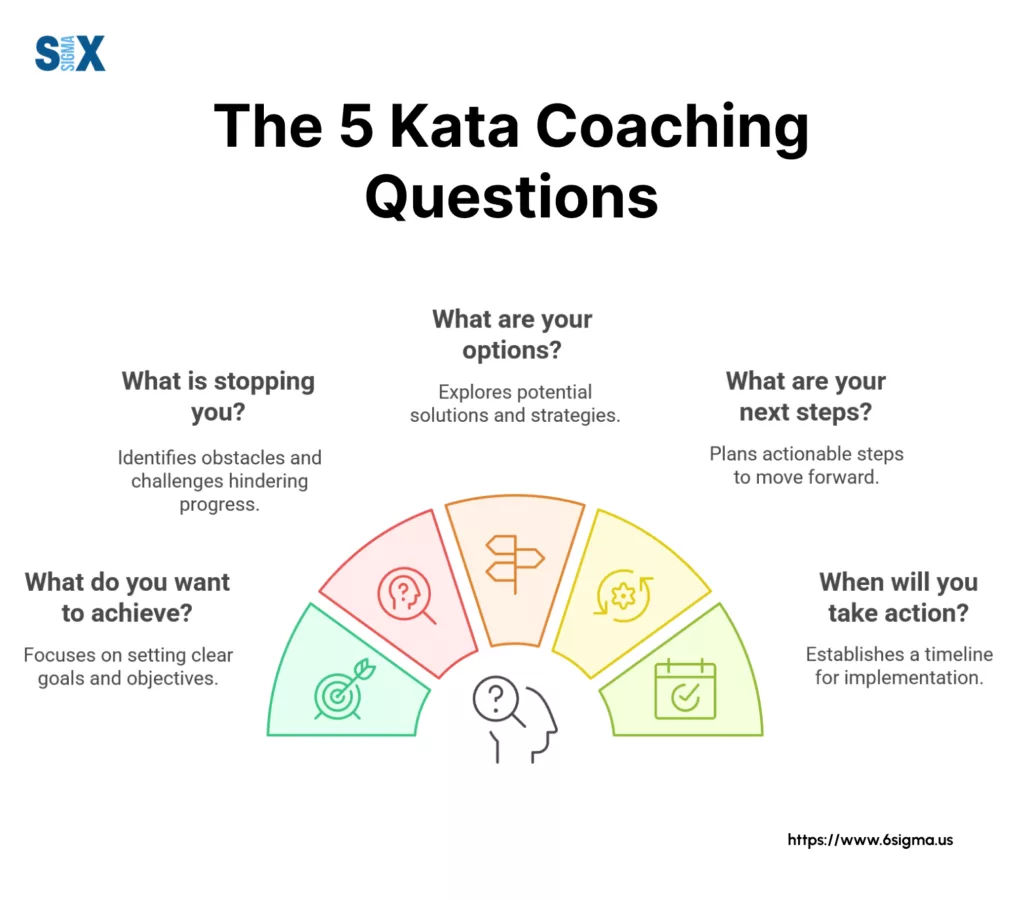

Mastering the Core: The 5 Kata Coaching Questions Explained

These five questions are the core of the Coaching Kata routine. When used consistently and with understanding, they are incredibly powerful for developing scientific thinking.

The Purpose Behind the Questions: Guiding Scientific Thinking

These kata coaching questions form a structured framework. Each question is specifically designed to prompt a certain part of the scientific thinking process embedded in the Improvement Kata.

They guide the learner to articulate their understanding, identify barriers, formulate experiments, and reflect on learning, step-by-step. It’s about reinforcing the pattern of thinking.

Question 1: What is the Target Condition?

(Coach asks the learner) “What is the Target Condition?”

The purpose here is laser focus. We’re not talking about the big, audacious overall challenge (that’s step 1 of the Improvement Kata). This question drills down to: “What specific, measurable state are we trying to achieve for this process in the near future (e.g., by next week)?”

As the coach, my job here is to listen carefully. Is the target condition clear? Is it measurable? Does it directly contribute to the overall challenge? If it’s vague, like “make things better,” I’ll gently push back – “Better in what specific way? How would we measure that?” Clarity here prevents wasted effort.

Question 2: What is the Actual Condition Now?

(Coach asks) “What is the Actual Condition Now?”

Okay, if that’s the target, where are we really starting from? This question demands facts and data about the current state, directly relevant to the target condition. “Well, I think we’re doing about 10 per hour…” isn’t good enough.

As a coach, I’m probing for objective evidence. “How do we know that? What does the data from the last shift show? Can we go see?” We need a clear, factual baseline – the actual condition – to measure progress against and to understand the gap we need to close. Assumptions are the enemy here.

Question 3: What Obstacles Do You Think Are Preventing You…? Which ONE Are You Addressing Now?

(Coach asks) “What Obstacles do you think are preventing you from reaching the Target Condition? Which ONE are you addressing now?”

This is critical. Now that we know the gap (between actual and target), what’s in the way? The first part encourages brainstorming potential obstacles. The second part – “Which ONE are you addressing now?” – is pure gold. It forces prioritization.

In my experience, teams often try to tackle too many obstacles at once and achieve nothing. Good kata coaching helps the learner focus their efforts on the single biggest (or most logical next) impediment. We can list many obstacles, but we only work on one at a time between coaching cycles.

Question 4: What Is Your Next Step (Experiment)? What Do You Expect Will Happen?

(Coach asks) “What is your next step (or your next experiment)? What do you expect will happen?”

With the single obstacle identified, what’s the very next action the learner will take? This defines the next PDCA cycle. But crucially, it’s not just “What will you do?” but also “What do you expect will happen?” This forces the learner to formulate a hypothesis. What specific outcome do they predict from this action (this experiment)?

As the coach, I’m checking: Is this a genuine experiment to learn something, or just implementing a known solution? Is the expectation clear and measurable? This prediction is vital for the learning that comes next.

Question 5: How Quickly Can We Go and See What We Have Learned…?

(Coach asks) “How quickly can we go and see what we have learned from taking that step?”

Finally, this question closes the loop and sets up the next learning cycle. It establishes when the experiment will be complete and, importantly, when the coach and learner will review the results. The emphasis is on speed – rapid cycles foster faster learning.

The goal is to compare what actually happened with what was expected (from Question 4). That gap between expectation and reality is where the most valuable learning occurs in kata coaching. My role as coach is to ensure this follow-up is scheduled promptly, keeping the momentum going.

Implementing Kata Coaching Effectively in Your LSS Environment

Knowing the questions is one thing; applying the kata coaching method effectively requires attention to detail, practice, and avoiding some common traps. Let’s look at how you can set it up for success and the nuances of the coaching interaction itself.

Setting Up Kata Coaching Cycles

You can’t just casually implement this kata coaching model. It needs structure. First, think about frequency. Ideally, coaching cycles are short (maybe 5-15 minutes) and frequent – often daily.

This allows for rapid learning loops. Waiting a week between check-ins defeats the purpose of quick experiments. Second, location matters. Whenever possible, conduct these cycles at the “Gemba” – the actual place where the work is done. This keeps the conversation grounded in reality.

You’ll also need some simple tools. A visual storyboard (like an A3 sheet or even a dedicated whiteboard section) where the learner tracks their Challenge, Target Condition, Actual Condition, Obstacles, and PDCA cycles is essential.

It makes the thinking visible and serves as the focal point for the coaching conversation. Finally, set expectations clearly with the learner. Explain the purpose of kata coaching (developing their skills, not judging them) and how the process works.

The Art of the Coaching Dialogue: Beyond Asking Questions

Here’s where the real skill of the coach kata comes in. Just rattling off the five questions isn’t effective lean kata coaching. It’s about the dialogue.

- Active Listening: You need to really listen to the learner’s answers, not just wait for your turn to ask the next question. What are they saying? What aren’t they saying?

- Open-Ended Follow-Ups: Don’t be afraid to gently probe. If an answer is vague, use follow-ups like, “Can you tell me more about that?” or “What makes you say that?”

- Tone is Crucial: Maintain a supportive, curious, yet challenging tone. You’re there to help them stretch their thinking, not interrogate them or make them feel inadequate. Building trust is paramount.

- Procedural Guidance vs. Solutions: This is the hardest part for many new coaches, especially technical experts like many of us engineers! Your instinct might be to jump in with answers (“Oh, you should just try X!”). Resist! Instead, provide procedural guidance.

- Bad Example (Giving Solution): Learner: “I’m not sure how to get the data.” Coach: “Just ask Sarah in IT, she has the report.”

- Good Example (Procedural Guidance): Learner: “I’m not sure how to get the data.” Coach: “Okay, where might that kind of data usually reside? Who typically works with that system? What could be your next step to find out?”

The second approach guides the learner to solve the problem of how to get the data themselves, reinforcing their problem-solving skills.

Avoiding Common Pitfalls: Mistakes New Kata Coaches Make

I’ve seen many well-intentioned kata coaching efforts stumble because the coach falls into common traps. Trust me, these are easy to do, especially when you’re busy. Effective kata coaching training often focuses heavily on avoiding these:

- Giving the Answers: We just talked about this. It’s the #1 mistake. It short-circuits the learner’s thinking process.

- Judging Ideas: Phrases like “That’ll never work” kill psychological safety and experimentation.

- Focusing Only on Results: Praising only successful experiments discourages learning from failures (which are often more valuable!). Focus on the learning and the process.

- Not Sticking to the Questions: Going off on tangents or turning it into a general chat dilutes the focus. Use the 5 questions as your guardrails.

- Infrequent Coaching Cycles: Weekly check-ins are too slow for the rapid learning cycles Kata aims for.

- Turning it into a Status Report: The coach just listens to updates without probing the thinking process behind them.

- Take a moment and reflect honestly: Which of these pitfalls might you be most susceptible to? Awareness is the first step.

Adapting Kata Coaching: Beyond the Manufacturing Floor

While Toyota Kata originated in manufacturing, I’ve successfully applied the principles of kata coaching across numerous sectors. The core – developing scientific thinking to tackle challenges – is universal. Don’t think this is just for production lines.

- Healthcare: Imagine using the 5 questions to guide a nursing team trying to reduce patient admission times. What’s the target admission time? What’s the actual now? What obstacles (paperwork, bed availability, communication)? What’s the next experiment to address one obstacle (e.g., changing a form)?

- IT/Software Development: Teams can use it to tackle development bottlenecks or improve bug resolution times within sprints. Target condition: reduce average bug fix time to X hours. Actual condition: Y hours. Obstacle: unclear bug reports. Next step: experiment with a new bug reporting template.

- Finance/Service: Optimizing invoice processing, reducing call center wait times – any process with a gap between the current state and a desired future state can benefit. The thinking pattern applies.

The key is to adapt the context of the examples and data, but the underlying kata coaching structure and the focus on the learner’s thinking process remain the same. It’s incredibly adaptable.

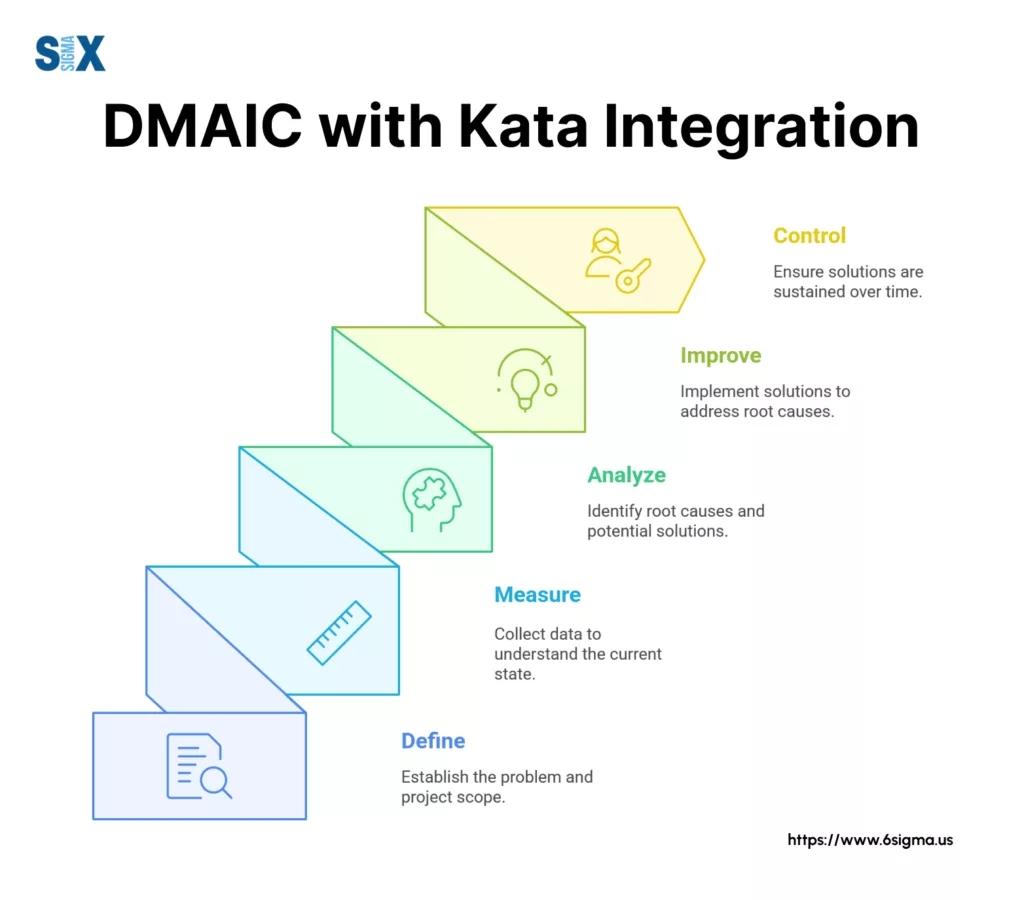

Synergizing Kata Coaching with the DMAIC Framework

Think of lean kata coaching not as an alternative to DMAIC, but as a powerful booster engine you can integrate throughout the familiar five phases.

It addresses the method of continuous learning and adaptation that complements the structured problem-solving of DMAIC. Here’s how I see the synergy playing out:

Enhancing Define & Measure

In the Define phase, we set the project charter and scope. In Measure, we establish baseline performance. The Improvement Kata’s emphasis on “Grasping the Current Condition” deeply resonates here.

Using kata coaching cycles early on can help teams rigorously challenge assumptions about the current state and iteratively refine the project’s target condition based on real data, ensuring we’re tackling the right problem with a clear understanding from the start.

Driving Analyze & Improve

This is where kata coaching really shines during the core DMAIC phases. In Analyze, we identify root causes, leveraging techniques often covered in root cause analysis training. In Improve, we develop and test solutions. Instead of just implementing a large-scale pilot, think about using rapid Improvement Kata / Coaching Kata cycles here.

We can frame potential root causes or countermeasures as hypotheses. Then, the team uses quick PDCA experiments, guided by the coach, to test these ideas on a small scale, learn quickly, and adapt.

It makes the Analyze and Improve phases much more dynamic and iterative, reducing the risk of implementing ineffective large-scale solutions.

Solidifying Control: Kata as the Engine for Sustainment

For me, this is where lean kata coaching offers the most significant advantage over traditional DMAIC implementation. The Control phase is about locking in the gains, often through standard work and monitoring.

Kata coaching provides the mechanism to make this dynamic, not static.

- It reinforces adherence to new standard work through the coach’s regular check-ins.

- Crucially, it builds the habit and skill of scientific problem-solving directly within the frontline team who owns the process long after the project team leaves.

- When performance inevitably drifts slightly (as it often does), the team doesn’t just flag it – they have a practiced routine (the Improvement Kata, guided by kata coaching) to understand why it’s drifting and experiment their way back to the target condition, or even beyond.

It empowers the frontline staff, builds ownership, and creates an engine for ongoing, incremental adjustment and sustainment – key goals often emphasized in comprehensive six sigma certification programs. Challenge: Think about the Control Plan from your last Lean Six Sigma project.

Challenge: Think about the Control Plan from your last Lean Six Sigma project. How could you map out a simple kata coaching cycle (using the 5 questions) to support the daily monitoring and response outlined in that plan? It shifts control from a passive document to an active, learning-based routine.

Embedding Continuous Improvement Habits with Kata Coaching

Kata coaching is a structured method – leveraging the twin routines of the Improvement Kata and the Coaching Kata, particularly those vital 5 Questions – designed to deliberately practice and instill the habits of scientific thinking. It’s about moving beyond just solving today’s problem to building the capability within your people to navigate uncertainty and continuously adapt, day in and day out.

Its synergy with Lean Six Sigma is incredibly powerful. While DMAIC gives us a robust framework for tackling bigger projects, kata coaching provides the engine for ongoing learning and, crucially, for achieving that often-elusive goal of genuine, long-term sustainability.

I strongly encourage you to start small. Identify one simple process, one willing learner, and begin practicing. Don’t aim for perfection initially; aim for practice and learning – for both you and your learner.

That’s the Kata way. Good luck building those improvement muscles!

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs