Lean Transformation Framework: A Step-by-Step Plan to Drive Profitability and Build Your Business Case

What if the biggest barrier to your company’s growth isn’t the market, but the waste hidden within your own processes?

It’s a challenge many leaders face: customer orders are delayed, internal costs creep up, and teams feel burdened by inefficient workflows.

There is a proven, strategic methodology designed to solve these very problems. This is the power of a lean transformation.

Ready to Start Your Lean Journey?

Grasp the core principles that power every successful transformation. This foundational course is the perfect first step for individuals and teams new to Lean thinking.

This guide is more than a simple definition; it’s a strategic roadmap for implementing a lean transformation that directly impacts your bottom line.

We will show you not only how to execute this fundamental change but how to build an undeniable business case for it that will win over stakeholders. Achieving this level of efficiency isn’t accidental; it’s a structured process.

Key Highlights

- How to define lean for profitability.

- A 5-stage implementation roadmap.

- How to avoid common transformation failures.

- How to build your business case.

What is Lean Transformation?

To truly lead a successful change, a deep understanding of lean transformation is essential. It’s a term that goes far beyond typical corporate jargon.

It isn’t about one-off projects or minor tweaks; it’s a comprehensive, top-to-bottom shift in an organization’s culture, mindset, and daily operations.

Beyond Buzzwords: A Practical Lean Transformation Definition

So, what is lean transformation at its core?

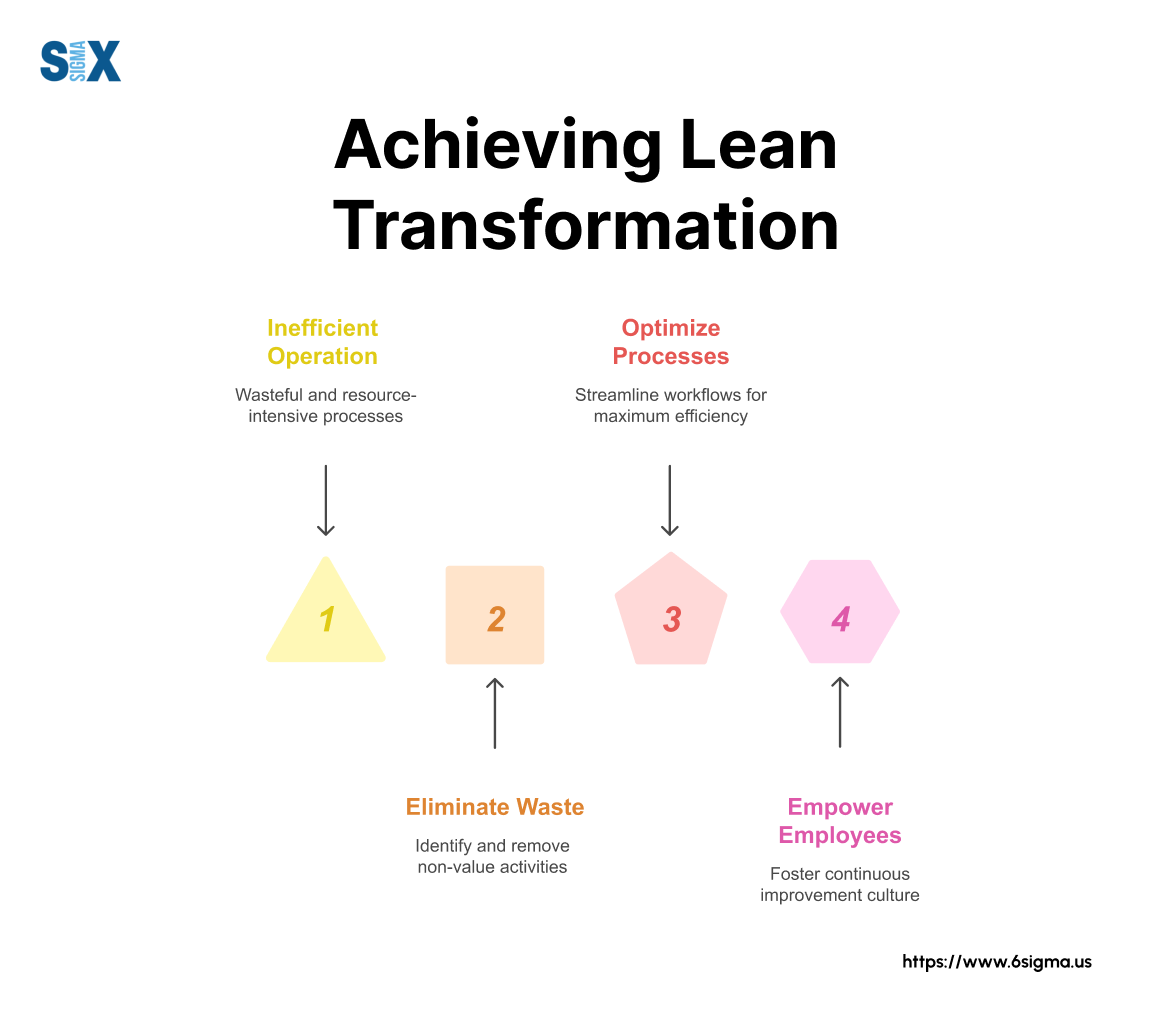

A lean transformation is a proactive, strategic overhaul of a company’s processes and culture to relentlessly eliminate waste and maximize value for the customer.

Unlike isolated improvement projects that may fix a single symptom, a true lean transformation rewires the entire organization to continuously seek out and solve problems.

This state of transformation lean means moving from a traditional, siloed management approach to one where every employee is empowered to improve the way work gets done.

A clear lean transformation definition always centers on two things: delivering exceptional value to the customer and creating a culture of respect and engagement for the people doing the work.

The “Why”: Connecting Lean to the Bottom Line

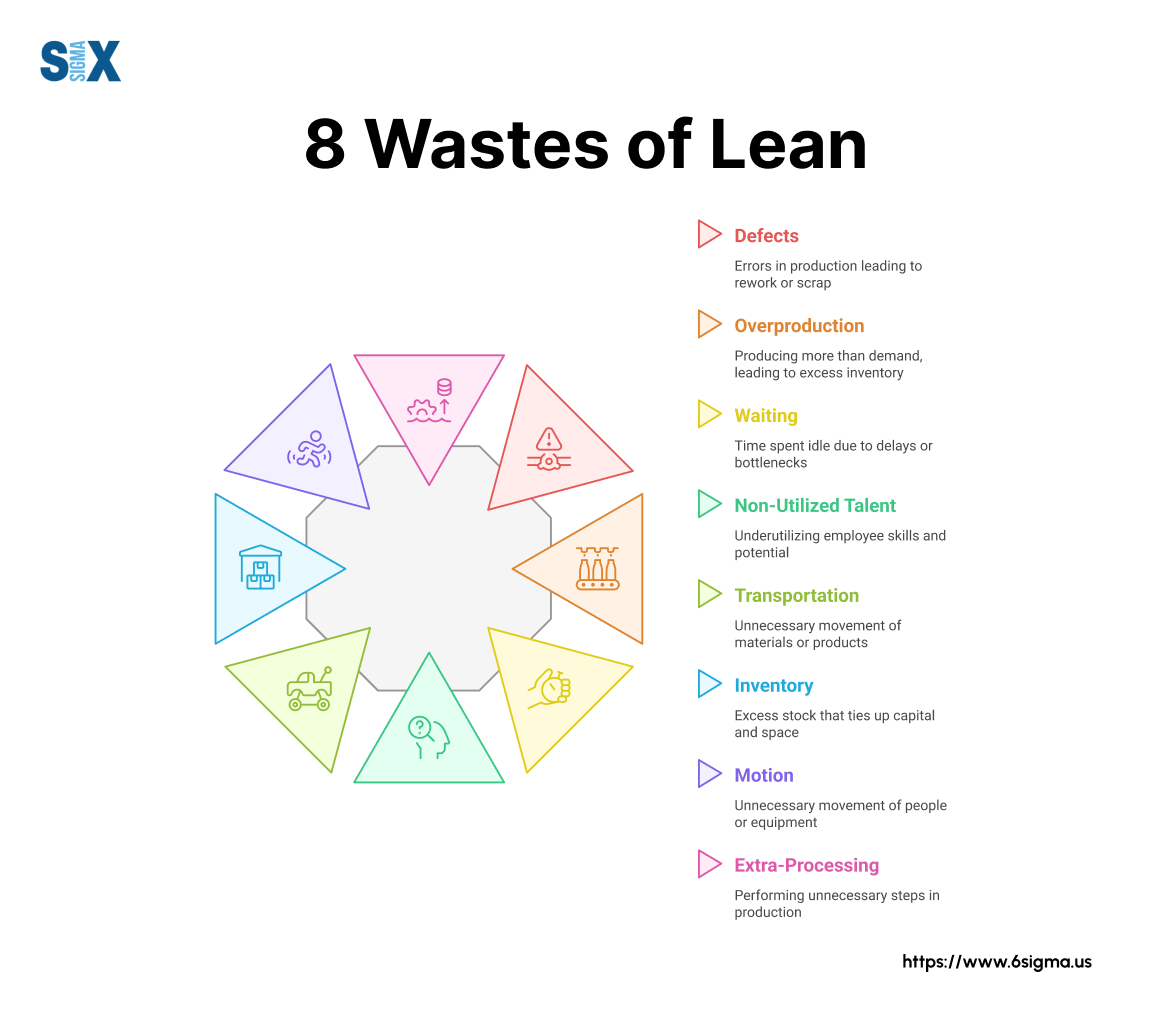

Now for the most critical question: Why is lean transformation important for your business? The answer lies in its direct impact on profitability by systematically attacking the “8 Wastes of Lean” These are activities that consume resources but add no value to the customer.

When your organization learns to see and eliminate these wastes, the results are powerful:

- Costs decrease as you stop paying for rework, excess inventory, and inefficient movement.

- Speed increases as waiting times and process bottlenecks disappear, leading to faster delivery to your customers.

- Quality improves as you prevent defects instead of just fixing them.

This isn’t just theory; it’s a proven path to financial health. Companies that undergo successful lean transformations have seen productivity increase by up to 50%.

This direct link between operational efficiency and financial performance is why a lean transformation is one of the most powerful strategies a modern business can deploy.

Master the Fundamentals

Go beyond the definition. This course covers the essential principles and tools you need to start identifying waste and seeing opportunities for improvement in your own work.

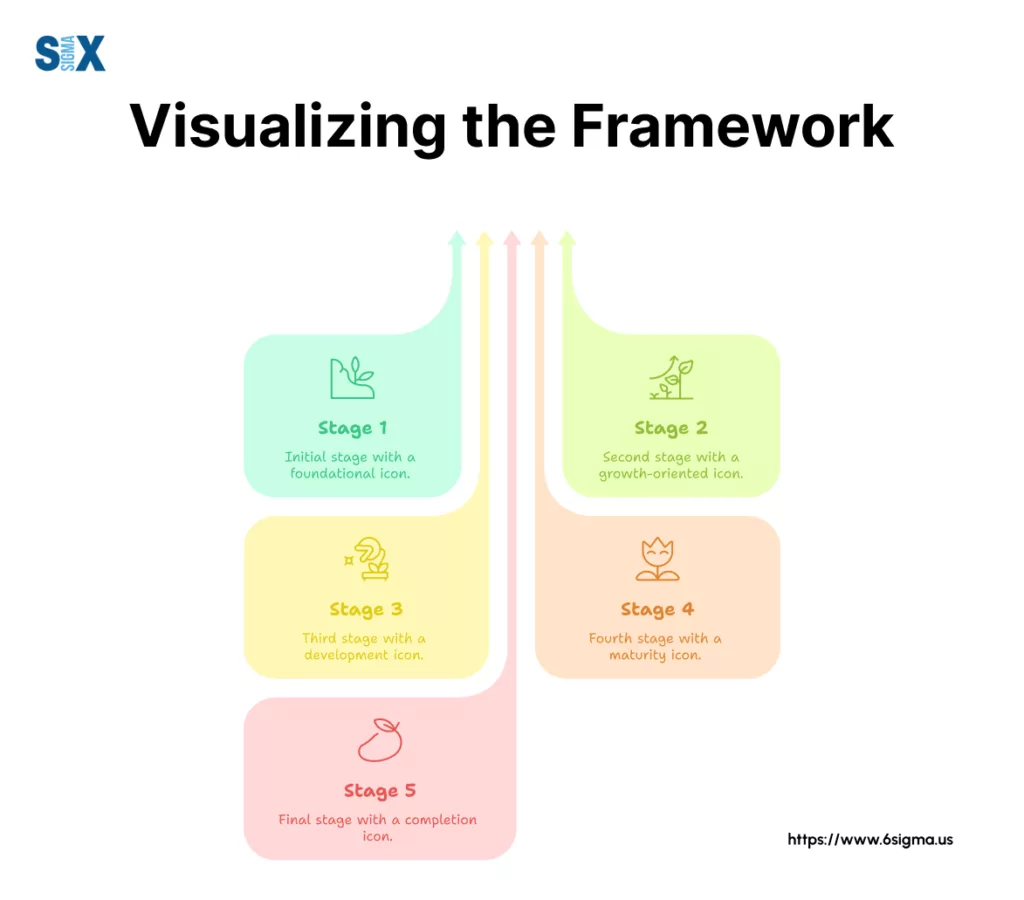

The 5-Stage Lean Transformation Framework: Your Roadmap from Plan to Profit

A successful lean transformation doesn’t happen by accident; it follows a structured and deliberate path. Think of this as your master lean transformation roadmap, guiding you from initial concept to lasting profitability.

While every organization is unique, this proven 5-stage lean transformation framework provides the essential structure for navigating the complexities of change and ensuring your efforts deliver real results.

Stage 1: Situational Analysis & Strategic Goal Setting

Before you can chart a course to your destination, you must know your starting point. The first of the lean transformation steps involves a deep, honest assessment of your current state.

This is where you develop your initial lean transformation plan.

- What it involves: Use tools like Value Stream Mapping (VSM) to visualize your entire process, from customer request to final delivery. The goal is to identify bottlenecks, waste, and areas of frustration. This phase is critical because any effective lean transformation is built on deeply understanding the root causes of problems, not just chasing symptoms.

- Key Question: Where is value being lost in our current processes?

Stage 2: Securing Leadership Buy-In & Aligning the Organization

A lean transformation is a significant undertaking that requires unwavering support from the top. Once you have your initial findings, the next step is to build a compelling case for change.

This involves more than just presenting data; it means aligning the proposed lean transformation strategy with the company’s highest-level business objectives, a crucial step for any lean enterprise transformation.

Show leadership how improving processes will help them achieve their goals, such as increasing market share or boosting profitability.

- What it involves: Translate your findings from Stage 1 into the language of business: cost savings, revenue opportunities, and risk reduction.

- Key Question: How does this transformation help our entire business win?

Stage 3: Building Capability Through Training & Development

For a lean transformation to be sustainable, you must empower your people with the right skills and mindset. This stage is about building an internal army of problem-solvers.

The lean transformation implementation cannot be done to your team; it must be done with them. This requires a tiered approach to training, ensuring everyone has the knowledge appropriate for their role.

- What it involves:

- For broad awareness, foundational concepts can be introduced through a Six Sigma White Belt certification, getting everyone familiar with the basic vocabulary of improvement.

- Team members who will actively participate in projects benefit from a Six Sigma Yellow Belt certification, which equips them with fundamental tools.

- Those tasked with leading improvement projects need the robust problem-solving methodologies taught in a Six Sigma Green Belt certification.

- To lead major cross-functional projects and mentor others, individuals should pursue a Six Sigma Black Belt certification.

- Finally, those who will shape the entire strategic direction and train others require the highest level of expertise, achieved through a Six Sigma Master Black Belt certification.

- Key Question: Does our team have the skills to drive and sustain this change?

Build Your Team of Problem-Solvers

Explore our complete Six Sigma certification path to find the right training for everyone on your team.

Stage 4: Execution – Deploying Pilots and Scaling Success

With leadership alignment and a trained team, you are ready to begin the hands-on lean transformation process. It’s wise to start with a high-impact pilot project.

Choose an area with a visible problem and a high likelihood of success.

A quick win from the pilot will build incredible momentum and serve as a powerful proof-of-concept for the rest of the organization.

- What it involves: Execute the pilot project, measure results meticulously, and communicate the success widely. Use the lessons learned to refine your approach before scaling the lean transformation to other departments or value streams.

- Key Question: How can we demonstrate value quickly and learn from our actions?

Stage 5: Sustaining Momentum with Continuous Improvement

The biggest mistake is treating a lean transformation like a project with an end date. The goal of the final stage is to embed the principles of lean into your company’s DNA.

This is the transition from “doing lean” to “being lean.” Success here means creating a culture of Kaizen (continuous improvement) where everyone, every day, is looking for ways to make the work better.

- What it involves: Establish standard work, set up visual management boards to track performance, and conduct regular process reviews. Crucially, leadership must continue to champion the initiative, recognize contributions, and reward the desired behaviors. This ensures the entire Six Sigma certification framework becomes a part of your operational identity.

- Key Question: How do we make continuous improvement a permanent part of our culture?

Examples of Profitable Lean Transformation

The principles of lean transformation are not just theoretical; they have been proven time and again in the real world, delivering dramatic results for companies across countless industries.

These examples provide the tangible proof needed to build a powerful business case.

The Classic: Toyota’s Manufacturing Revolution

No discussion of lean is complete without mentioning its origin: the Toyota Production System (TPS). In the post-war era, Toyota faced immense resource constraints and could not compete with the mass-production models of American automakers.

In response, they engineered a revolutionary system focused on one thing: eliminating waste to create a seamless, efficient flow of value to the customer.

This was the birth of the modern lean transformation.

- The Result: Instead of building cars in massive, inefficient batches, Toyota created a system that could produce high-quality vehicles in a matter of days, not weeks.

- They reduced inventory, minimized defects to near-zero, and empowered employees to continuously improve the process. This relentless focus on efficiency didn’t just make them competitive; it made them a global leader and set the standard for operational excellence worldwide.

Beyond the Factory: Lean in Financial Services

The power of the lean transformation method is its universal applicability. It is just as effective in an office environment as it is on a factory floor.

Consider the case of a major bank that was struggling with its mortgage application process. It was slow, riddled with errors, and frustrating for both customers and employees.

By applying lean principles, the bank mapped out its entire value stream and identified dozens of non-value-added steps: redundant data entry, unnecessary handoffs between departments, and long wait times for approvals.

- The Result: Through a focused lean transformation, they redesigned the entire workflow. The outcome was staggering: the average time to process a loan application dropped from 30 days to just 24 hours.

- This not only slashed operational costs but also dramatically increased customer satisfaction and boosted application volume, giving them a significant competitive advantage. This proves that no matter the industry, a lean approach can unlock hidden capacity and value.

Many companies striving for these kinds of breakthrough results find that the most effective path is to partner with experts.

Why Lean Transformations Fail (And How to Guarantee Yours Succeeds)

Embarking on a lean transformation is a powerful commitment, but the path is often littered with challenges. The hard truth is that many transformation efforts fall short of their goals or fizzle out after a few initial successes.

Understanding the common reasons for failure isn’t about discouragement; it’s about strategic preparation.

By anticipating these pitfalls, you can build a resilient strategy that guarantees your success where others have stumbled.

Pitfall #1: Lack of Genuine Leadership Commitment

This is the number one reason a lean transformation fails. It occurs when leadership offers only passive support—approving the budget but failing to back it up with meaningful action.

They don’t actively participate in reviews, use their authority to remove organizational barriers, or most importantly, change their own behaviors to align with lean principles. When the team sees that leaders aren’t truly invested, the initiative is doomed.

- Success Strategy: Your data-driven business case is your most powerful tool. It’s not just for getting initial approval; it’s for securing a mandate. Tie the transformation directly to the strategic goals and KPIs that your leaders are measured against.

- When they see the lean transformation as the most effective way to achieve their objectives—like increasing market share or boosting profitability—their commitment will shift from passive support to active, visible championship.

Pitfall #2: Focusing on Tools, Not on People and Culture

Many organizations fall into the trap of “tool-based lean” They get excited about implementing Kanban boards, 5S workplace organization, or daily huddles, but they miss the most important part: changing the underlying mindsets and behaviors.

When you focus only on the tools, you get the appearance of lean without the substance—a phenomenon often called “lean theater“. The tools are present, but the culture of continuous improvement and respect for people is absent.

- Success Strategy: Treat the tools as what they are: enablers of a philosophy, not the philosophy itself. The goal is to build a culture of problem-solvers who understand the “why” behind their actions. This means education must come first.

- Weaving cultural change into every step of the fundamentals of Lean training ensures your team understands the core principles of customer value, flow, and waste elimination before they ever pick up a tool.

Pitfall #3: Poor Communication and Employee Resistance

If a lean transformation is perceived as something being done to employees rather than by and with them, it will be met with fear and resistance.

When people don’t understand the purpose of the change, they naturally assume the worst—often worrying about job security or that this is just another management fad. This resistance, whether it’s spoken or unspoken, can quietly sabotage the entire effort.

- Success Strategy: Develop and execute a transparent and continuous communication plan. Start by explaining the “why”—the business challenges you’re trying to solve and the opportunities you want to seize for everyone’s benefit.

- Involve employees from the front lines in diagnosing problems and designing new solutions. This builds ownership and turns potential resistors into your most enthusiastic supporters. Finally, celebrate small wins publicly to build momentum and prove that the change is positive for everyone.

Navigate Change with an Expert Guide

Worried about the pitfalls? Our expert consultants can help you design a transformation strategy that avoids common failures and aligns your entire organization for guaranteed results.

Building Your Bulletproof Business Case for Lean Transformation

You now understand the what, why, and how of a lean transformation. The final, and most critical, step is to translate that knowledge into a compelling business case that will secure the resources, budget, and leadership commitment you need to move forward.

This is where you combine a powerful narrative with hard data to create an undeniable argument for change.

To make this process as simple as possible, we have created a downloadable guide you can use to structure your presentation.

Step 1: Define the Problem and Opportunity in Dollars and Cents

The most effective business cases begin by grounding the problem in financial reality. Vague statements like “our processes are slow” are easy to ignore.

Quantifiable costs are not. Work with your finance and operations teams to translate inefficiencies into a language everyone understands: money.

- How to do it: Instead of saying, “We have too much rework,” present it as, “Our current defect rate of 4% in the assembly department costs us an estimated $1.2M annually in wasted materials and labor.” Instead of “customers are waiting too long,” state, “Our average order fulfillment time of 21 days is 40% longer than the industry average, putting us at a competitive disadvantage.”

Step 2: Outline the Proposed Lean Transformation Approach

Once you’ve established the cost of the problem, present your clear, structured solution. Use the 5-stage framework from this guide as your proposed plan.

This shows that you have a well-thought-out methodology, not just a vague idea. This section outlines your overarching lean transformation strategies.

- How to do it: Clearly define the scope of your initial efforts. Specify the value stream or department where you will launch a pilot project. State the expected outcomes clearly, such as, “We will pilot this lean transformation approach in the XYZ department with the strategic goal of reducing lead time by 50% and defects by 75% within the first six months.”

Step 3: Projecting the ROI and Timeline

Here, you connect the costs of the transformation (e.g., training, time investment) to the projected financial benefits.

This is the Return on Investment (ROI) calculation that executives will focus on.

- How to do it: Create a realistic financial projection. Be conservative but confident in your estimates for cost savings and potential revenue increases. When it comes to the timeline, be honest: a full lean transformation is a multi-year journey. However, emphasize that the results from the pilot project can deliver a significant ROI and be clearly visible within just 3-6 months, demonstrating early value and justifying further investment.

Step 4: Presenting the Plan and Securing Your Mandate

Your final step is to present your case. Your delivery is as important as your data. Speak with confidence, focusing on how the lean transformation aligns with the company’s key strategic priorities—whether that’s growing market share, improving customer satisfaction, or increasing profitability.

- How to do it: For complex transformations, the credibility of your plan is significantly boosted when the project is led by someone with deep, recognized expertise in process improvement.

- This is why having a certified Six Sigma Black Belt at the helm can be the decisive factor in gaining approval and ensuring the initiative’s ultimate success. They possess the advanced problem-solving and project management skills to navigate the complexities of large-scale change.

Conclusion

A lean transformation is more than just a set of tools; it is a fundamental commitment to achieving operational excellence and sustainable profitability.

Throughout this guide, we’ve shown that a successful transformation hinges on a structured, 5-stage framework, a keen awareness of the cultural pitfalls to avoid, and most importantly, a data-driven business case to secure unwavering support.

You now have the knowledge and the roadmap to not only understand lean transformation but to confidently lead one within your organization, turning process improvement into a powerful engine for growth.

Your next step is to turn this knowledge into action.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs