Six Sigma Leadership Profile: Apple

Steve Jobs dropped out of Reed College, Oregon, in early 1974. He then pursued a brief career with the Atari Corporation designing video games. After a pilgrimage to India where he first encountered Buddhism. It was in late 1974 when Jobs reconnected with an old school friend by the name of Steve Wozniak. Deciding to go into business together, Jobs and Wozniak set to work on what would be the beginning of a new computer revolution. The two technology entrepreneurs built their computer logic board in Jobs’ garage using money from selling Wozniak’s programmable calculator and Jobs’ Volkswagen minibus. They called it the Apple I.

In 1977, The Apple Corporation was officially founded. The Apple II began producing that same year, revolutionizing the computer market. The Apple II was an immediate success and has become synonymous with the personal computer boom. Much of the Apple Corporation’s success is due to its early victories in the computer market, bolstering their place in the technology sector. On the fast track to fame, the company’s 1981 public stock offering broke all previous records. In 1983, Apple was quick to be placed on the Fortune 500 list of top companies in America. Since then, Apple has become one of the most innovative and influential technology companies the world has ever seen.

Much like Microsoft or Sony, Apple is a household name, with millions of people using Apple products every day worldwide. To date, Apple has sold over 700 million iPhones and are constantly improving their formula, always striving for better products. Did Six Sigma have a hand to play in the success of both Jobs and Apple? We think so. There are many instances where Jobs and Apple both clearly applied Six Sigma, Lean, and Kaizen-oriented thinking to their production processes and business strategies. Today we look at the many parallels between them all.

Six Sigma Practices at the Core of Apple

Steve Jobs has come to be synonymous with history’s greatest innovators and inventors. However, the secret to Jobs’ success, and thus Apple’s, is not that he invented a tangible product. Even Henry Ford didn’t invent the automobile, and he based his notions of flow production and interchangeable parts on existing ideas. Similarly, Jobs didn’t invent the computer. He didn’t invent the graphical interface. Nor did Jobs create the first music player, the music itself, the telephone, or the tablet computer. Just like Henry Ford, Jobs brought many disparate ideas together, conglomerating them as a single product. Something few people had ever thought to do before.

Similarly, under Jobs’ watchful eye, Apple maintained more in-house operations than any other company in the technology industry. Jobs himself worked on hardware design, software, operating systems, web services, consumer devices, as well as retail. He always insisted on the seamless integration of all these features, holding to this strategy even when the industry he worked in shunned his ideas. Apple was unlike other companies, which chose to fragment and stretch their production through outsourcing.

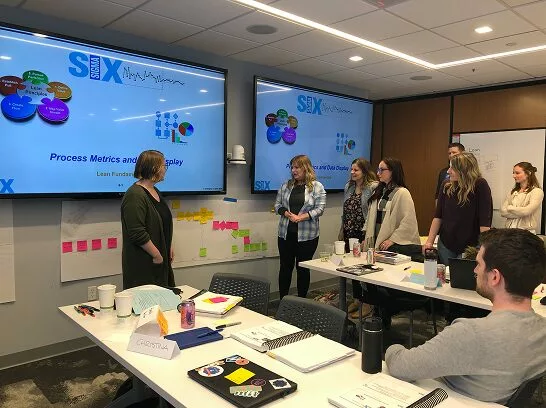

Learn More About Our Six Sigma Green Belt Training

But Jobs recognized the importance of cooperation between closely-knit departments within his corporation. On an interesting note, the Mackintosh was reportedly first produced using just-in-time manufacturing techniques. You should note that this was around the same time GM and Toyota reopened the old GM factory in Freemont, California. Furthermore, the cutting-edge facility where Apple produced the Mackintosh was in walking distance from the NUMMI plant there. Coincidences like these make it impossible to disregard Six Sigma, Lean, and Kaizen’s influence on Jobs and Apple. Even if the former didn’t always conform to these philosophies.

Apple and Continuous Improvement

Steve Jobs was a driven man. He possessed an unrelenting drive for improvement. While he may not have embodied all aspects of kaizen, his thinking in terms of supply chains was a major factor in Apple’s future success. Vertical integration is important here. It describes the process of one company combining multiple production stages each normally operated by separately. Jobs extended vertical integration to dealers, a ground-breaking move that, like Henry Ford, revolutionized his supply chain.

Furthermore, Jobs famously said, “You can’t just ask customers what they want and then try to give that to them. By the time you get it to build, they’ll want something new.” This is perhaps the greatest parallel between Six Sigma and Jobs’ thinking. Jobs was renowned for his product process innovation, believing he knew his customer’s needs better than they did. Jobs based his decision-making on the vision of what Apple’s products could do for its customers, as opposed to market research and direct feedback. With Jobs at the helm, Apple’s mission was to solve customer need completely by predicting it for them.

By designing products to meet future need, Apple gained an added edge over its competitors. All the products Apple has produced have been incredibly successful. This is due largely to the fact that they streamlined their production and their products, leaving out any none-value-adding technology. Doing so allowed them to create products that were simple, yet innovative, user-friendly, yet highly sophisticated and efficient.

Jobs’ Legacy at Apple

Without Steve Jobs, there would be no Apple. Since before and after his death in 2011, Jobs has become known the world over as a pioneering technology entrepreneur. Jobs was one of the first to recognize the potential of the personal computer. He understood how it could appeal to a wide demographic, and did something about it. In fact, Jobs was a noted advocate of Six Sigma and Lean, ever-striving to achieve Kaizen’s culture of continuous improvement.

Jobs is the most important figure in Apple’s history by far. But not because of any specific technical contribution he made to the company. What’s more important is that Jobs understood the social and technological zeitgeist of his time. He knew what was needed and strove to make that a reality. Jobs integrated his products and processes with a ground-breaking business model to transform the technology sector forever. Never settling for anything less than the best, Apple is above all a company for which Six Sigma, Lean, and Kaizen are all important.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs