A Lean Six Sigma Guide to Eliminating Supply Chain Bottlenecks & Boosting Profitability

A single, unseen supply chain bottleneck can silently drain millions from your bottom line before it’s even formally identified.

For many managers, this reality leads to a state of constant firefighting—a chaotic cycle of managing unpredictable delays, placating frustrated customers, and dealing with the costly pile-up of excess inventory. This reactive approach is not only exhausting; it’s unsustainable.

But what if you could move from operational chaos to proactive control? This guide provides that path.

Solve Your Bottlenecks Now!

Our Lean Six Sigma programs provide the framework to transform your supply chain. See how our training can empower your team to build a more resilient operation.

We’ll explore how the disciplined, data-driven framework of Lean Six Sigma offers a permanent solution to the question of what are supply chain bottlenecks.

You will learn how the principles of Lean can fundamentally reframe your approach, transforming these operational headaches into a powerful and lasting competitive advantage.

Key Highlights

- See bottlenecks as solvable process waste.

- Use data to find root causes.

- Apply Lean Six Sigma for solutions.

- Boost profitability with certified teams.

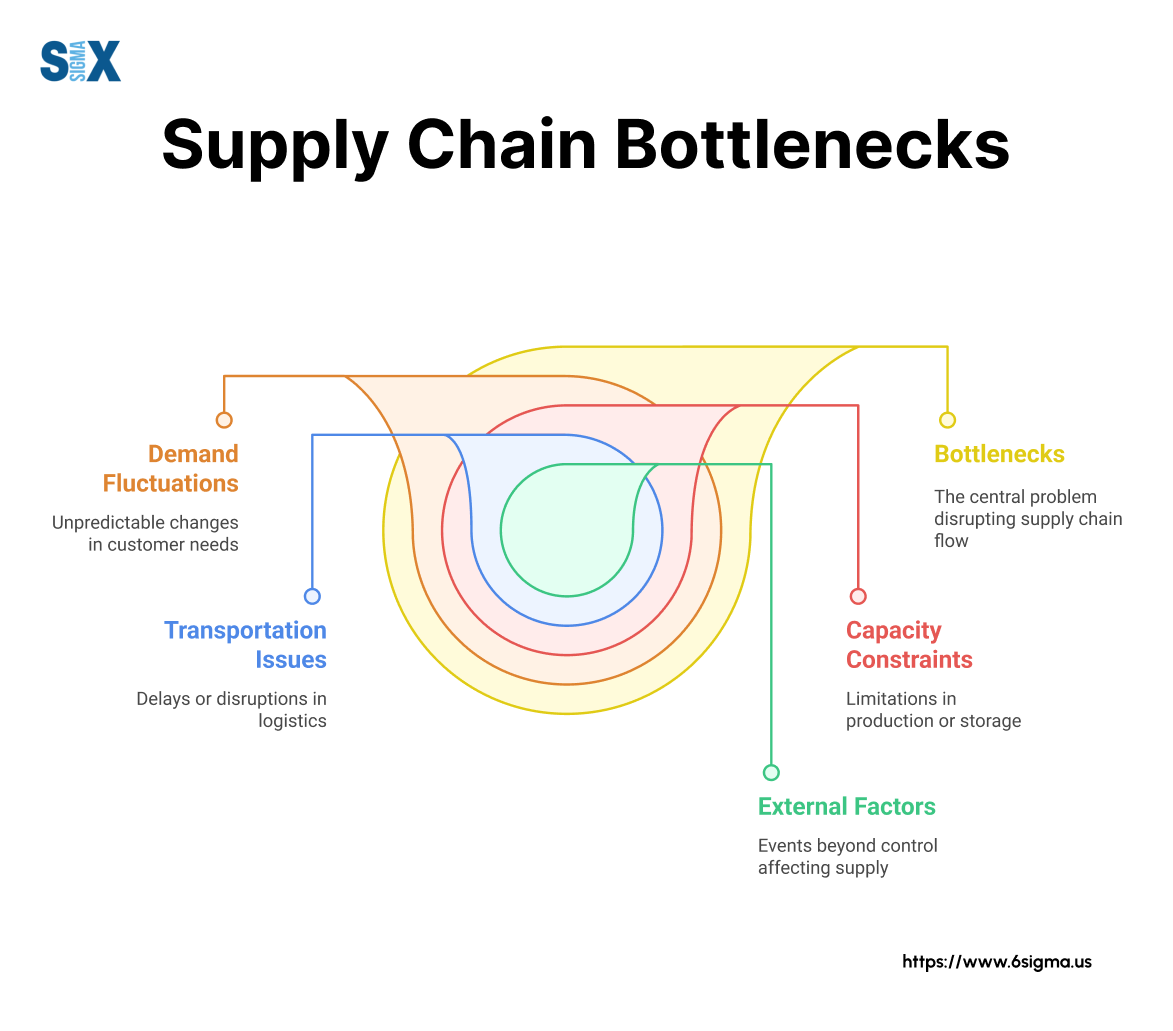

What is a Supply Chain Bottleneck? (And Why It’s More Than Just a Delay)

At its simplest, a supply chain bottleneck is any point in an operational process where the workload arrives faster than that point can handle it.

Imagine a four-lane highway abruptly merging into a single lane during rush hour. The result is a massive, slow-moving traffic jam that backs up for miles.

In your business, this “traffic jam” isn’t just an inconvenience; it’s a critical disruption that radiates across the entire organization.

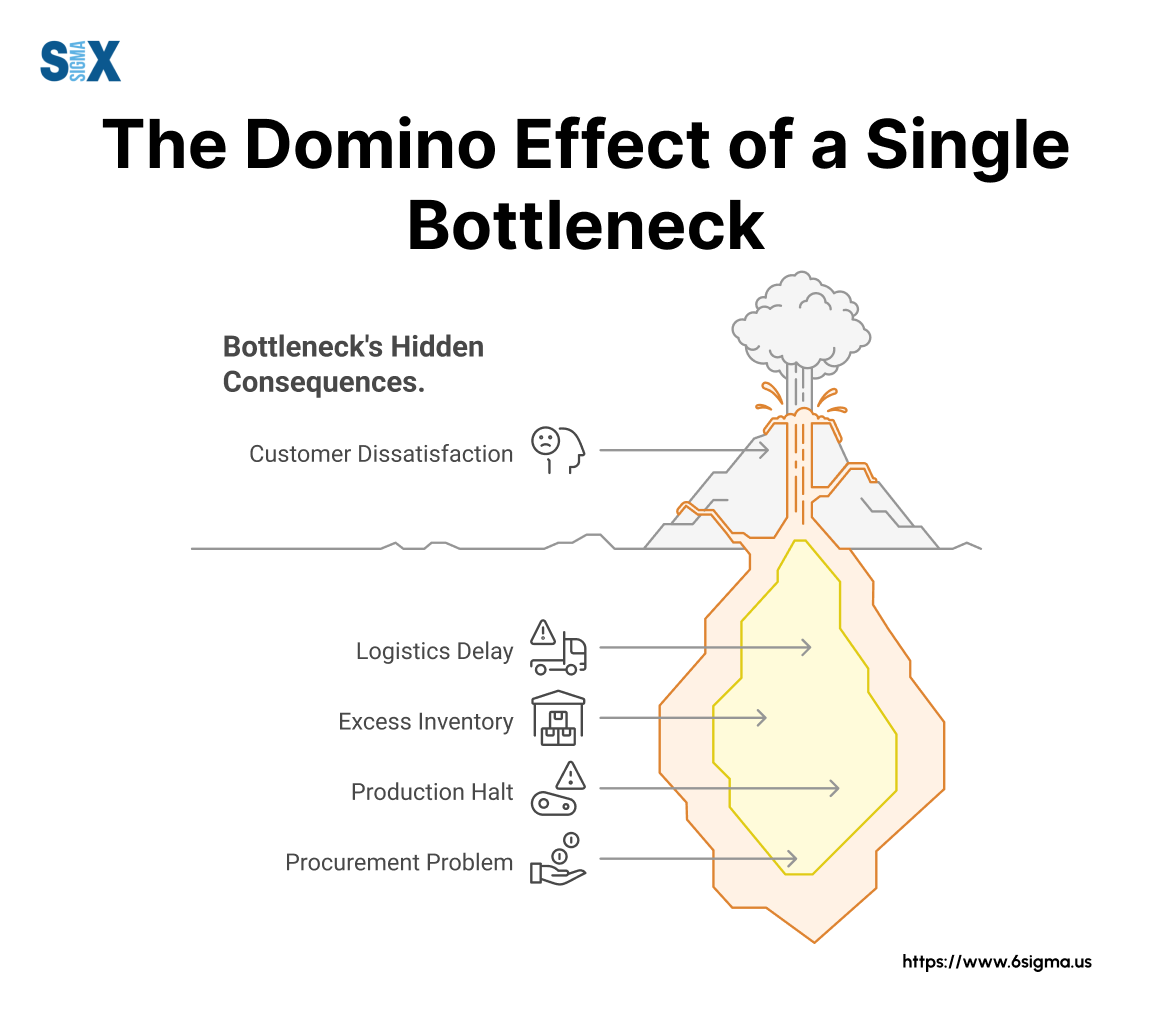

A single bottleneck in the supply chain creates a domino effect. It leads to increased operational costs from overtime and expedited shipping, ties up capital in excess inventory, and ultimately results in broken promises to your customers through shipping delays and stockouts.

This erodes customer satisfaction and damages your brand’s reputation.

However, from a process improvement perspective, a bottleneck is something more specific: it is a major source of “Muda“, the Japanese term for Waste.

When you truly understand the core concepts of Lean, you begin to see a bottleneck not just as a slow point, but as a generator of multiple forms of waste—the waste of waiting for materials, the waste of excess inventory piling up, and the waste of defects that occur when rushing to compensate.

Viewing bottlenecks through this lens transforms them from a frustrating reality into a clear target for improvement.

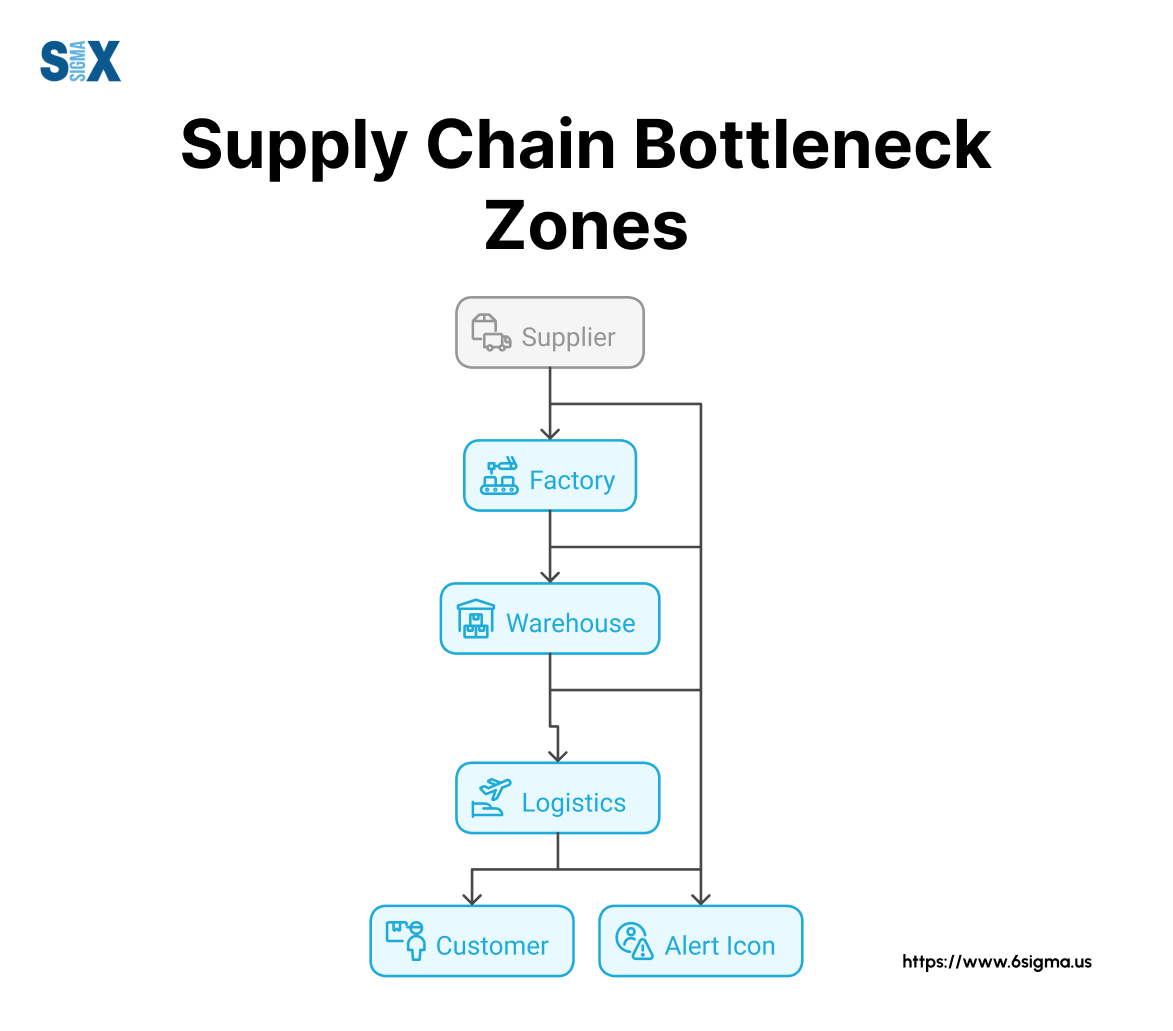

Where Bottlenecks Hide: The Most Common Culprits in Your Supply Chain

Identifying where the supply chain bottlenecks are is the first step toward resolving them. While a bottleneck can technically occur at any stage, they most frequently emerge at critical handoff points or in resource-constrained processes.

Understanding these common hotspots allows you to focus your diagnostic efforts where they will have the greatest impact.

Procurement and Supplier Management

The beginning of the supply chain is often its most vulnerable point. Bottlenecks in the supply chain here are common and can include:

- Single-Source Dependency: Relying on a single supplier for a critical component creates extreme risk. Any disruption they face—from financial trouble to a factory fire—becomes your disruption.

- Unreliable Performance: Suppliers who consistently miss delivery dates, have long lead times, or provide poor-quality materials force your entire production schedule into a reactive mode.

- Geopolitical and Logistical Delays: Global events, trade disputes, or shipping port congestion can instantly halt the flow of materials before they even reach your facility.

Internal Operations and Production

Your own facility can be a primary source of bottlenecks. Look for constraints in:

- Machine Capacity and Downtime: A single machine that is slower than the rest of the line, or one that breaks down frequently, will dictate the maximum output of your entire operation.

- Inefficient Processes: Poorly designed workflows, unnecessary steps, or a lack of standardized work can create artificial choke points that slow down production.

- Labor Shortages or Skill Gaps: Not having enough people—or not having people with the right training—to operate key equipment or perform specific tasks is a frequent cause of operational delays.

Inventory and Warehouse Management

The way you store and move goods can either facilitate flow or create significant roadblocks. Common issues include:

- Poor Forecasting: Inaccurate demand forecasting leads to either stockouts (halting production/sales) or excess inventory (tying up capital and warehouse space), both of which are forms of waste.

- Disorganized Layouts: An inefficient warehouse layout that requires excessive travel time to pick and pack orders creates a major bottleneck, especially during periods of high demand.

Logistics and Transportation

Even a perfect product can be derailed by final-stage bottlenecks:

- Customs and Regulatory Hurdles: For international shipping, delays at customs can hold up products for days or even weeks.

- Transportation Network Failures: A shortage of truck drivers, limited carrier capacity, or disruptions at major shipping hubs can stop your products in their tracks.

- Last-Mile Delivery Inefficiencies: The final leg of the journey to the customer is often the most complex and prone to delays, directly impacting the customer experience.

Diagnosing the Problem: How to Identify and Analyze Your Supply Chain Bottlenecks

Once you know where bottlenecks are likely to hide, you need a systematic process to expose them.

Effective bottleneck supply chain management isn’t about guesswork; it’s about being a detective, using both qualitative observation and quantitative data to uncover the truth.

This diagnostic phase is where the Six Sigma methodology truly begins to shine, providing a clear framework for analysis.

Step 1: Seeing the Signs (Qualitative Analysis)

Data tells only part of the story. You must also understand the process in its real-world context.

- Process Mapping: Create a visual flowchart of the entire process from start to finish. This exercise often immediately reveals redundant steps, delays, and illogical handoffs that are invisible on a spreadsheet.

- Gemba Walks: “Go and see.” Walk the physical path of the process—whether on the factory floor or in the warehouse. Observe the work as it happens and speak directly with the frontline employees who experience the friction firsthand. Their insights are invaluable for understanding why there are supply chain bottlenecks.

Step 2: Following the Data (Quantitative Analysis)

Your observations must be validated with hard numbers. Tracking the right Key Performance Indicators (KPIs) will pinpoint exactly where flow is being constricted.

Key metrics to monitor include:

- Cycle Time: The total time it takes to complete a specific task or process from start to finish. A high cycle time in one area compared to others is a red flag.

- Throughput: The amount of product produced or units processed over a specific period. A process with consistently low throughput is a likely bottleneck.

- Lead Time: The total time from a customer order to final delivery. Analyzing lead time components can reveal which stage is causing the most significant delays.

- On-Time Delivery Rate: A declining on-time delivery rate is a lagging indicator that one or more upstream bottlenecks are impacting the customer.

Step 3: Getting to the Source with Root Cause Analysis

Identifying a bottleneck is not the same as solving it. Quick fixes often address the symptoms, leaving the underlying problem to reemerge later. The goal is to find the root cause—the fundamental issue that, if fixed, will prevent the problem from recurring.

- The “5 Whys” Technique: A simple but powerful method. Start with the problem (e.g., “The product shipped late”) and ask “Why?” five times, drilling down with each answer to uncover the core issue.

- Fishbone (Ishikawa) Diagram: A more structured tool used to brainstorm and categorize potential causes of a problem across different categories like People, Processes, Materials, and Equipment.

True resolution begins when you apply a structured approach to solving supply chain bottlenecks, ensuring you’re fixing the foundational problem, not just patching the cracks in the wall.

Start with the Fundamentals

Build a solid foundation for your process improvement journey by understanding the core principles that drive efficiency and eliminate waste.

The Solution Framework: Applying Lean Six Sigma to Create a Resilient Supply Chain

Identifying your bottlenecks is a crucial diagnostic step, but the real value lies in systematically eliminating them. This is where Lean Six Sigma provides a powerful, data-driven framework.

It moves your organization from a reactive state of crisis management to a proactive culture of continuous improvement, building a supply chain that is not only efficient but truly resilient.

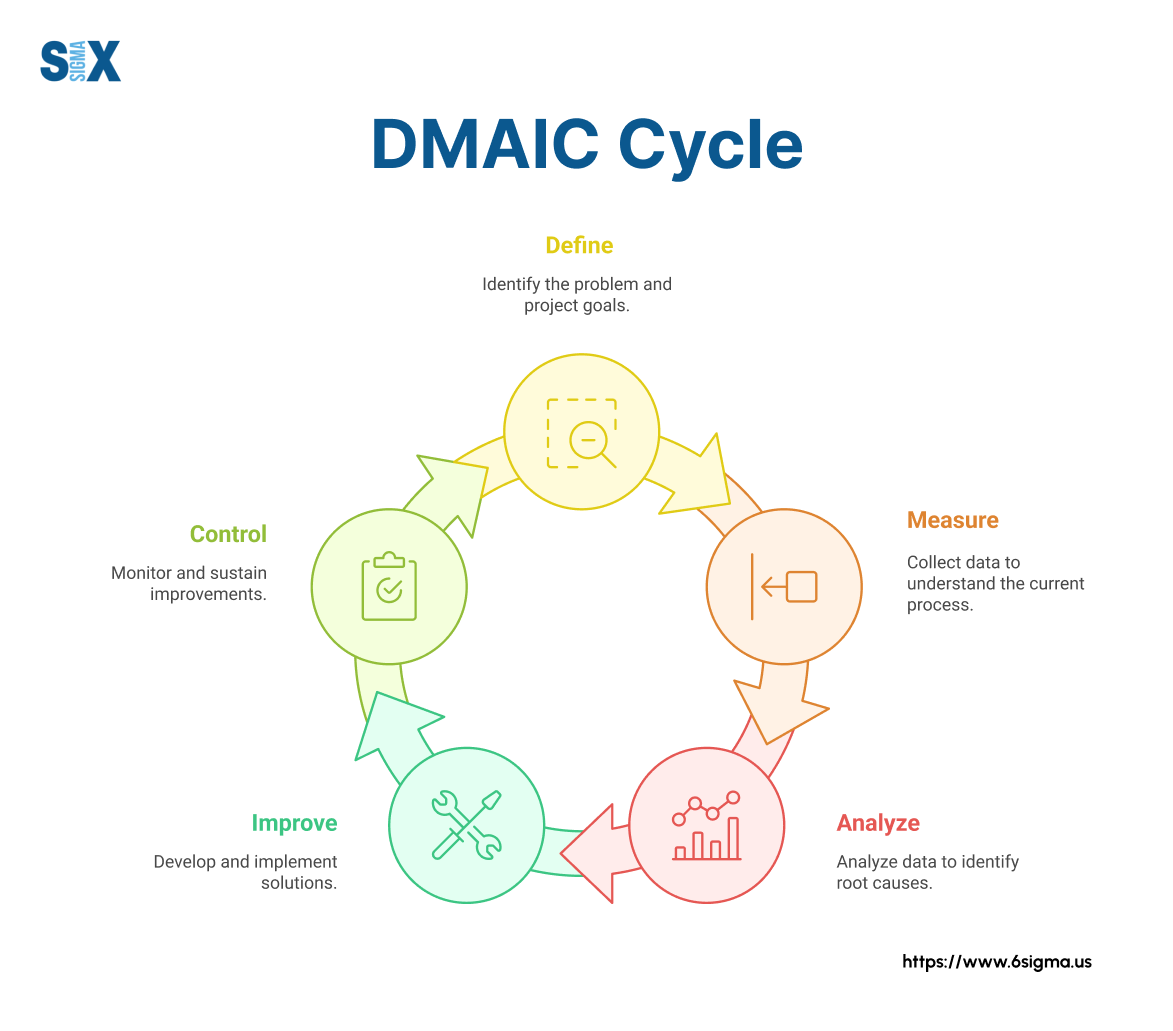

The DMAIC Roadmap: Your Five-Step Battle Plan

At the core of Six Sigma is the DMAIC methodology, a five-phase roadmap for solving problems and improving processes. It provides the structure needed to ensure solutions are effective and sustainable.

- Define: Clearly define the problem (the bottleneck), the goals of the project, and the customer requirements.

- Measure: Collect data to quantify the current process performance and the magnitude of the problem.

- Analyze: Analyze the data to identify the root cause(s) of the bottleneck.

- Improve: Develop, test, and implement solutions that address the root cause.

- Control: Establish measures to maintain the gains and ensure the process stays improved.

This structured approach prevents “solution-jumping” and ensures your efforts are focused on changes that will have a real, measurable impact.

Building Your Problem-Solving Team: The Role of Six Sigma Belts

Solving bottlenecks in the supply chain requires a team effort, and Lean Six Sigma provides a structure for developing talent at all levels. Different scales of problems require different levels of expertise.

- Creating Foundational Awareness: To build a true culture of quality, everyone in the organization should understand the basic language of process improvement. A Six Sigma White Belt Certification provides this essential awareness, ensuring your entire team can recognize waste and support improvement initiatives.

- Empowering Team Contributors: Many bottlenecks are identified and solved by those closest to the work. Employees who can support improvement projects by gathering data and contributing ideas often benefit from getting their Yellow Belt. They become valuable members of any project team.

- Developing Project Leaders: For tackling a significant, department-level bottleneck, you need a dedicated project leader. Professionals with Six Sigma Green Belt certification & training are equipped with the analytical tools and project management skills to lead improvement teams and deliver measurable results.

- Deploying Expert Analysts: For complex, cross-functional bottlenecks that are deeply embedded in your operations, a statistical expert is required. This is the domain of a Black Belt, who can manage multiple projects and use advanced analytics to solve the most challenging business problems. Achieving Black Belt certification signifies mastery of the tools needed to drive significant financial returns.

- Fostering Strategic Mentorship: At the enterprise level, driving a culture of continuous improvement requires strategic oversight and mentorship. For deploying Lean Six Sigma across an entire organization and coaching other belts, the highest level of Six Sigma certification is the Master Black Belt, who serves as an in-house consultant and strategic leader.

Find Your Place in Process Improvement

Each Six Sigma Belt plays a unique role in solving problems and driving change. Discover which certification path best aligns with your career goals and your organization’s needs.

Using Technology as a Force Multiplier

Technology is not a replacement for a sound methodology, but a powerful accelerant. AI, predictive analytics, and process automation are modern tools that dramatically enhance the Lean Six Sigma framework. They can:

- Automate Data Collection (Measure): Instantly gather performance data that once took weeks to compile.

- Identify Patterns and Predict Bottlenecks (Analyze): Use AI to analyze vast datasets and flag potential bottlenecks before they occur.

- Optimize Solutions (Improve): Run simulations to test the impact of potential changes before implementing them in the real world.

When you combine a skilled team trained in Lean Six Sigma with modern technology, you create a formidable capability for building and maintaining a superior supply chain.

Your Path Forward: How to Start Building a Bottleneck-Resistant Operation

Understanding the principles of Lean Six Sigma is the first step. Translating that knowledge into a resilient, bottleneck-resistant operation is the journey.

Here is a clear path forward for you and your organization, whether you’re just beginning or are ready to tackle complex, systemic challenges.

Start with Education: Foundational Knowledge for Your Team

A culture of continuous improvement begins with a shared language and understanding. Before you can effectively solve problems, your team must learn to see the “waste” that bottlenecks create.

The most impactful first step is to provide key staff with an introduction to Lean fundamentals.

This foundational knowledge empowers individuals at all levels to contribute to a more efficient and collaborative operational environment.

Choosing Your Path: Which Certification is Right for You?

As you move from general knowledge to specific application, the question becomes one of capability. Different team members will play different roles, and their training should reflect that.

Unsure about where to begin your own professional journey? It’s important to choose the right certification based on your career goals and your organization’s specific needs.

For many who are new to process improvement but want to be active contributors, pursuing a Lean Six Sigma Yellow Belt certification is the perfect entry point.

To explore the full spectrum of capabilities you can build, you can review a range of Six Sigma training and certifications options to find the ideal fit.

When to Seek Expert Guidance

Sometimes, bottlenecks are so deeply embedded in legacy systems or complex processes that an external perspective is required to see the path forward.

If your organization is facing systemic challenges that require deep strategic intervention and a clear ROI, leveraging expert Lean Six Sigma guidance can accelerate your journey.

Professional consulting provides the strategic oversight and hands-on expertise to drive significant, lasting improvements to both your processes and your bottom line.

Become a Certified Project Leader

Lead improvement projects, eliminate waste, and deliver measurable results with Lean Six Sigma Green Belt certification.

From Constant Crisis to Continuous Improvement

Ultimately, supply chain bottlenecks are more than just operational hurdles; they are a critical form of process waste that directly impacts profitability and customer trust.

By moving beyond the endless cycle of reactive firefighting, you can begin to treat them systematically.

The Lean Six Sigma framework provides the proven, data-driven methodology to not only solve your current bottlenecks but to build a culture of continuous improvement that prevents them from reoccurring.

This strategic shift transforms your supply chain from a source of constant crisis into a powerful and resilient competitive advantage.

Build a more resilient, profitable operation to empower your team to tackle your most pressing challenges today.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs