Operational Cost Reduction: Slashing Expenses with Lean Six Sigma

What if a silent leak was draining up to 30% of your company’s revenue each year? For many businesses, this isn’t a hypothetical; it’s the reality of unchecked operational costs.

These inefficiencies—from wasted materials to redundant processes—are more than just expenses; they are barriers to growth and profitability.

Begin Your Transformation

Empower your team with the skills to identify waste and drive real cost savings. Our programs provide the foundation for operational excellence.

Key Highlights

- Slash operational costs with Lean Six Sigma.

- Use the DMAIC framework to cut waste.

- Learn the essential roles of Six Sigma Belts.

- Drive sustainable, data-backed business savings.

- Find the right certification path for you.

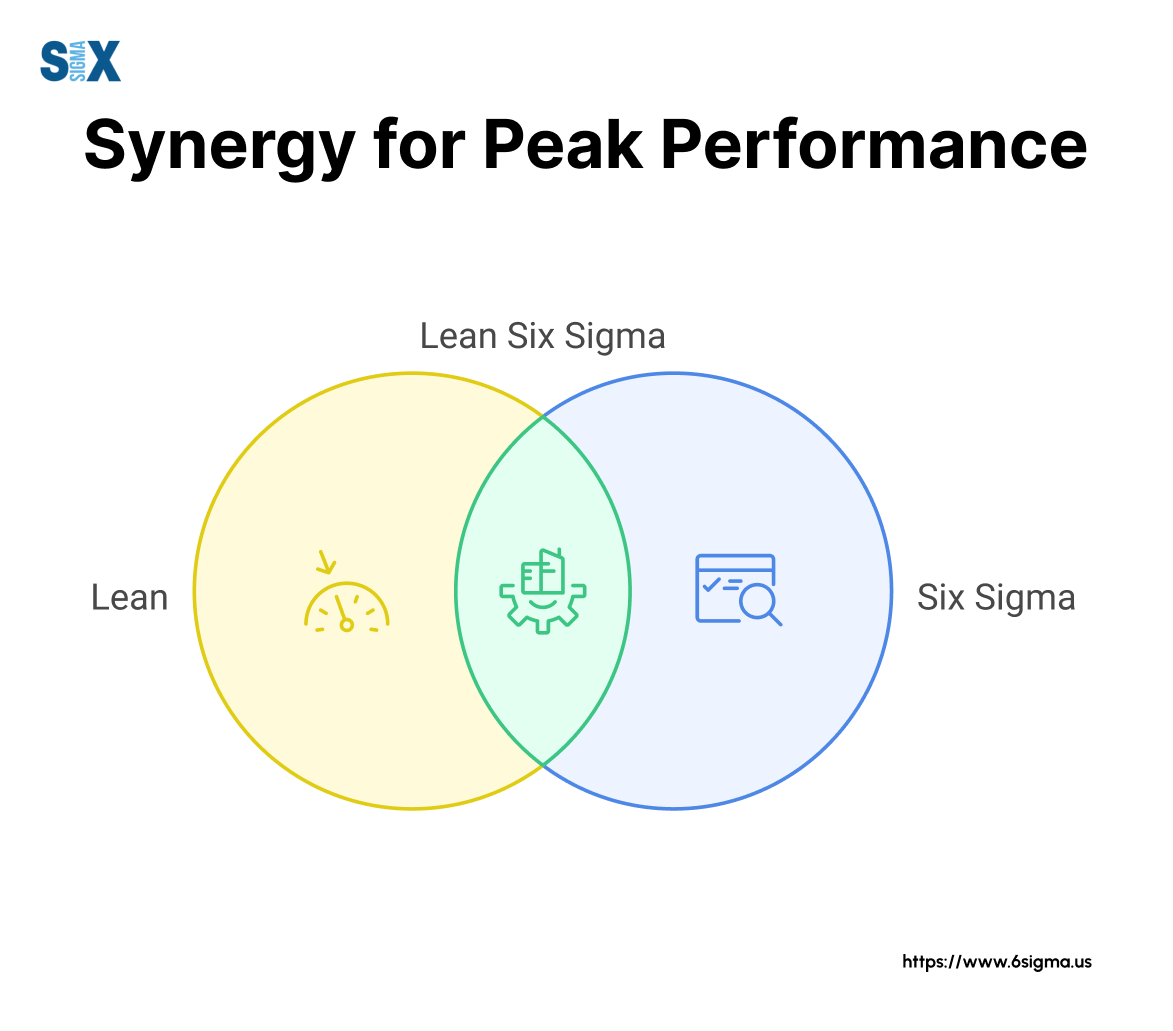

Lean Six Sigma: Your Framework for Profitability

Achieving a significant reduction of operational cost requires a structured approach.

That’s where Lean Six Sigma comes in, not as a single concept, but as the powerful fusion of two distinct, world-class methodologies.

Understanding this synergy is the first step toward transforming your operations.

First, Lean is all about speed and efficiency. Its primary goal is to ruthlessly eliminate “waste”—any activity that consumes resources but adds no value to the end customer.

This includes the eight classic wastes: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing. By streamlining processes and creating a smooth workflow, Lean cuts the fat from your operations.

On the other hand, Six Sigma is all about quality and consistency. Its goal is to reduce process variation and eliminate defects to a level of just 3.4 per million opportunities.

It uses a highly disciplined, statistical approach to make processes more predictable and reliable. When asking, “What is Six Sigma in operations management?” the answer is simple: it’s a system for ensuring that the work you do is done right, every single time.

When combined, lean six sigma and operational cost reduction become inseparable. Lean makes your processes faster and more efficient, while Six Sigma makes them more effective and error-free.

You’re not just doing things faster; you’re doing the right things faster and better.

This dual-pronged attack on inefficiency and inconsistency is what makes Lean Six Sigma the gold standard for businesses aiming to boost their bottom line. Understanding these foundations of Lean thinking is the first step toward significant savings.

Master the Fundamentals

Go deeper into the core concepts that power the world’s most efficient companies. A solid understanding of Lean is the first step toward optimization.

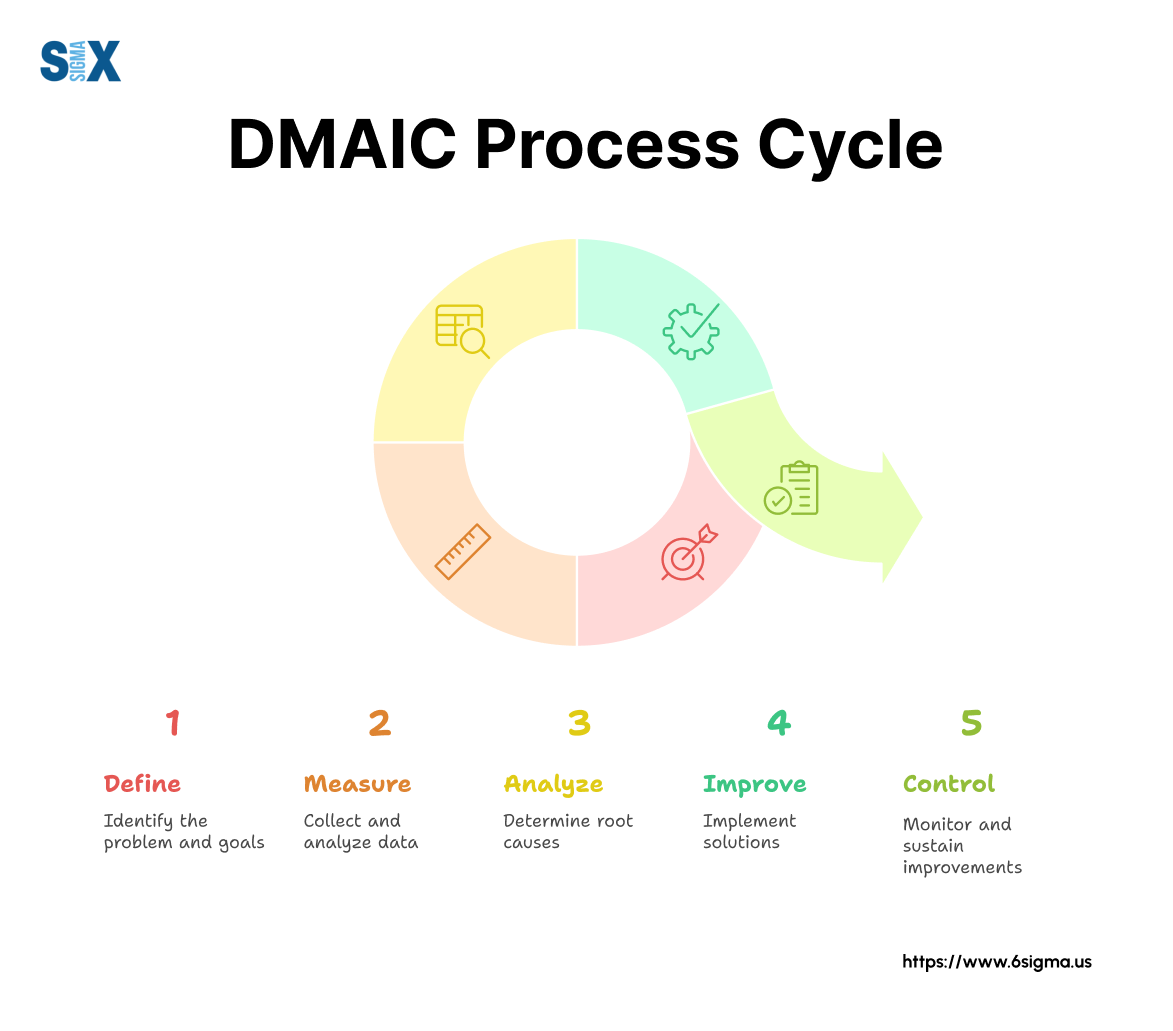

The DMAIC Cycle: A 5-Step Roadmap for Operational Cost Reduction

Lean Six Sigma moves beyond theory by providing a practical, five-step roadmap for executing projects: the DMAIC cycle.

This data-driven framework is the engine that powers successful cost reduction initiatives, ensuring that decisions are based on facts, not assumptions.

By following this cycle—Define, Measure, Analyze, Improve, and Control—teams can systematically uncover inefficiencies and implement lasting solutions.

Step 1: Define the Problem and Its Financial Impact

The first step in any DMAIC for operational cost reduction project is to get crystal clear on what you are trying to solve.

The Define phase is not about guessing; it’s about articulating a specific problem and quantifying its impact on the business.

Here, the team creates a formal project charter that outlines the project’s goals, scope, and timeline. A critical part of this stage is calculating the costs of poor quality (COPQ).

This isn’t just the cost of a scrapped product; it includes the wasted labor, lost production time, and even the potential impact on customer satisfaction.

For example, a clear problem statement would be: “Excessive rework on Production Line B due to material defects is currently costing the company an estimated $50,000 per quarter in labor and material waste.” This puts a dollar value on the problem, creating a compelling business case for moving forward.

Step 2: Measure the Current Process Performance

Once the problem is defined, the next step is to measure the current process to establish a baseline. You cannot know if you’ve improved if you don’t know where you started.

The Measure phase is all about data. The project team develops a data collection plan and uses tools like process mapping to visualize every step of the current workflow.

They gather precise metrics related to the problem defined in the previous phase—for example, measuring the exact number of defects per shift, the average time a task takes, or the amount of material wasted each day.

This phase provides the hard numbers that validate the problem statement and serve as the benchmark against which all future improvements will be judged.

Step 3: Analyze to Identify the Root Cause of Costs

With solid data in hand, the team moves into the Analyze phase, which is essentially the detective work of the Six Sigma process.

The goal here is to drill down past the surface-level symptoms to find the true root cause of the problem. Why are defects happening? Where are the bottlenecks that cause delays?

This stage uses a variety of powerful analytical tools, such as the 5 Whys (repeatedly asking “why” to peel back layers of symptoms) and Fishbone (Ishikawa) diagrams to map out all potential causes related to people, processes, materials, and equipment.

Mastering these techniques is central to effective improving operational efficiency and finding the source of cost overruns, ensuring that the team solves the core issue, not just its symptoms.

Step 4: Improve the Process to Eliminate Waste

After identifying the root cause of the problem in the Analyze phase, it’s time to develop and implement solutions. The Improve phase is where the change happens.

The team brainstorms potential solutions that directly address the verified root causes. For instance, if the analysis showed that defects were caused by inconsistent machine settings, the improvement might involve creating a standardized setup procedure or installing a new calibration tool.

These potential solutions are often tested on a small scale (a pilot) to confirm their effectiveness before a full-scale rollout.

The goal of this phase is to make tangible changes to the process that will demonstrably reduce defects, cut waste, and lower costs.

Step 5: Control the New Process to Sustain the Savings

Achieving a cost reduction is a victory, but sustaining it is what creates long-term value. The final phase, Control, is dedicated to ensuring the improvements stick.

The team develops a control plan to monitor the new process and its performance over time. This involves creating new standard operating procedures (SOPs), training employees on the updated workflow, and establishing key metrics to track.

This phase ensures that the process does not revert to its old, inefficient ways. It also incorporates the philosophy of Kaizen, or continuous improvement, cementing the new standard as the baseline for future optimization efforts and locking in the financial gains achieved by the project.

Find the Root of the Problem

Effective analysis is the key to solving problems permanently. Learn the advanced methods our experts use to uncover the true source of operational waste.

Building Your A-Team: The Six Sigma Roles That Drive Cost Reduction

Lean Six Sigma is more than just a methodology; it’s a cultural framework powered by skilled individuals. Its success within an organization depends on having people with the right training to lead and support projects.

This expertise is organized into a “Belt” system, much like in martial arts, where each level signifies a greater degree of mastery and responsibility. Understanding these roles is key to building a team capable of driving significant cost reduction.

White and Yellow Belts: The Foundation of Your Six Sigma Culture

Change begins at the grassroots level. White Belts have a basic awareness of Six Sigma concepts and terminology, allowing them to understand the goals of a project.

Even this introductory Six Sigma Certification can empower employees across the organization to spot potential inefficiencies in their daily work.

Yellow Belts take this a step further. They are trained in the fundamentals and often serve as valuable subject matter experts on project teams.

They help collect data, participate in brainstorming sessions, and assist with implementing solutions. Having team members with a Six Sigma Yellow Belt Certification is essential for project success, as they provide the on-the-ground support needed to execute changes effectively.

Six Sigma Green Belts: Your Project Team Leaders

Green Belts are the engines of a Six Sigma program. They are trained in the full DMAIC methodology and are equipped to lead small-to-medium-sized improvement projects under the guidance of a Black Belt.

They are the ones who work directly with front-line staff to apply Six Sigma tools to solve chronic problems and deliver tangible cost savings.

Empowering key team members by becoming a certified Green Belt is one of the most effective ways to drive meaningful change from within your organization.

Six Sigma Black Belts: The Experts and Mentors

Black Belts are full-time experts and leaders dedicated to process improvement. They possess a deep understanding of statistical analysis and lead the most complex, high-impact cost reduction projects.

Beyond leading their own initiatives, they serve as critical mentors and coaches for Green Belts, providing guidance and support.

For intricate challenges that span multiple departments and require sophisticated data analysis, achieving Black Belt certification provides the deep expertise required to ensure a successful outcome.

Six Sigma Master Black Belts: The Strategic Visionaries

At the highest level are the Master Black Belts. These individuals are the strategic leaders of an organization’s entire Six Sigma deployment.

They identify high-leverage project opportunities, align the improvement program with executive-level business goals, and mentor Black Belts and Green Belts.

The highest level of Six Sigma certification, the Master Black Belt, is responsible for embedding the continuous improvement culture across the company and ensuring its long-term success.

Which Six Sigma Belt is Right for You?

Whether you are an executive looking to implement a cost-saving culture, a manager tasked with improving a process, or an employee eager to contribute, there is a path for you.

If you’re unsure where to begin, selecting the right certification level is a critical first step on your Six Sigma journey toward professional growth and operational excellence.

Find Your Perfect Fit

Every role is crucial for success, from foundational support to strategic leadership. Compare the different Six Sigma Belts to find the right certification path for your career goals.

Six Sigma Case Studies on Cost Reduction

The principles of Lean Six Sigma are not just theoretical; they deliver tangible, measurable results. Across industries, organizations have used this methodology to solve complex problems and achieve astounding financial returns.

These six sigma projects for cost reduction examples illustrate how a disciplined, data-driven approach can turn operational challenges into strategic victories.

The following six sigma case studies on cost reduction show the methodology in action.

Case Study 1: Manufacturing Defect Reduction

A mid-sized automotive parts manufacturer was plagued by high levels of scrap and rework on one of its critical production lines, costing them over $1 million annually.

They initiated a six sigma cost reduction in manufacturing project led by a Black Belt.

- Define & Measure: They defined the problem as excessive defects and measured the baseline defect rate at 15%.

- Analyze: Using statistical analysis, the team identified that inconsistent temperature and pressure settings during the molding process were the root cause of the defects.

- Improve & Control: They implemented a new automated process control system to maintain consistent settings and trained operators on the new standards.

The Result: The defect rate dropped from 15% to less than 1%, slashing material waste and rework costs. The project saved the company approximately $950,000 in its first year and delivered a higher quality product to customers.

Case Study 2: Streamlining a Service Process

A large insurance company was struggling with a slow and costly claims processing system. The average time to close a claim was 22 days, leading to high administrative costs and poor customer satisfaction.

They focused on applying six sigma in service industry to cut costs.

- Define & Measure: They defined the problem as excessive processing time and mapped the entire claims journey, measuring the time spent at each stage.

- Analyze: The analysis revealed significant bottlenecks, including redundant data entry and long waits for supervisor approvals.

- Improve & Control: The team redesigned the workflow, eliminating unnecessary steps and empowering claims agents to approve claims up to a certain threshold. They also implemented a new digital document management system.

The Result: The average claims processing time was reduced from 22 days to just 6 days.

This dramatically lowered the labor cost per claim and led to a 40% improvement in customer satisfaction scores, demonstrating that Six Sigma is just as powerful in an office as it is on a factory floor.

Putting It All Together: Launching Your Cost Reduction Initiative

You’ve seen the framework, the roles, and the real-world proof. The journey of operational cost reduction through Lean Six Sigma is a structured path toward profound business transformation.

It’s about building a resilient, efficient, and competitive organization from the inside out. This isn’t just a one-time fix; it’s the beginning of a culture of continuous improvement, where every team member is empowered to identify and eliminate waste.

The first step is often the most important.

From Cost Center to Profit Driver

Ultimately, operational costs are not just a line item on a balance sheet—they are a direct reflection of your organization’s efficiency.

By embracing the principles of Lean Six Sigma, you can transform your operations from a cost center into a powerful engine for profit.

We’ve explored how the DMAIC framework provides a clear roadmap for improvement, how a team of certified Belts can drive change, and how real-world companies have achieved dramatic savings.

This is more than just cutting costs; it’s about building a smarter, more robust organization that consistently delivers higher quality at a lower expense.

Take the first step towards operational excellence.

Six Sigma & Cost Management FAQ

As you consider implementing Lean Six Sigma, specific questions naturally arise.

A. Six Sigma reduces costs by systematically identifying and eliminating the “Costs of Poor Quality” (COPQ).

This includes all expenses incurred from doing things wrong—such as creating defective products, repeating a service, wasting materials, and inefficient labor.

By using a data-driven approach to find the root cause of these issues, Six Sigma allows organizations to solve problems permanently, rather than just treating the symptoms.

A. In cost management, Six Sigma signifies a strategic shift from reactive cost-cutting to proactive cost optimization.

Instead of arbitrary, across-the-board budget reductions that can harm

productivity, Six Sigma targets the specific processes that generate waste.

It provides a surgical method for lowering expenses by improving the quality and efficiency of the work itself, leading to sustainable savings without disrupting value-added activities.

A. The application of Six Sigma is incredibly versatile and can reduce virtually all types of operational costs.

Common examples include:

– Labor Costs: By streamlining workflows and eliminating redundant tasks.

– Material Costs: By drastically reducing defects, scrap, and rework.

– Inventory Costs: By optimizing stock levels to better match production and demand.

– Energy Costs: Through more efficient use of machinery and facilities.

– Compliance Costs: By improving process consistency and reducing errors that can lead to fines or penalties.

A.

A cost-benefit analysis is a critical component of the “Define” phase in every Six Sigma project.

Before a project is approved, its potential financial savings and other benefits (like improved customer satisfaction) are carefully weighed against the estimated costs of executing it (including team member time and any necessary investments).

This ensures that resources are allocated to projects with a clear and compelling return on investment (ROI), aligning improvement efforts directly with the organization’s financial goals.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs