Overcoming the 7 Biggest Six Sigma Challenges: A Real-World Guide

You have the executive mandate. You’ve read the books and perhaps even have the certification. So why does implementing Six Sigma feel like pushing a boulder uphill in a hurricane?

You’re not alone. Most initiatives, even in well-run organizations, face a predictable set of hurdles that have more to do with people and politics than with processes and p-values.

While the Six Sigma methodology is statistically sound, its success on the ground hinges entirely on navigating these human-centric challenges.

Build Your Profitability Framework

A successful Six Sigma program begins with a clear strategy that connects every project to bottom-line results. See how our framework aligns process improvement directly with your organization’s financial goals.

This is the critical, often-overlooked bridge between process improvement theory and real-world profitability. For organizations truly committed to transforming their operations and boosting their bottom line, adopting a strategic approach from day one is essential.

It’s why many leaders seek expert Lean six sigma consultation to help build a robust implementation framework that anticipates these hurdles from the start.

Key Highlights

- Identify the top real-world hurdles.

- Turn common challenges into opportunities.

- Navigate the human side of change.

- Sustain improvements for long-term profit.

Challenge 1: Lack of True Leadership Commitment

There is a common barriers to Six Sigma, that projects fail without leadership buy-in. While true, this is a dangerous oversimplification.

The common wisdom suggests that a signature from a C-level executive is all you need to get started. But this passive approval is often where the problem begins.

The unspoken truth is that true commitment isn’t a signature on a project charter; it’s active, visible championship.

The biggest barrier to successful Six Sigma adoption isn’t always the executive suite; it’s the “messy middle“. Middle managers, department heads, and supervisors are the ones who feel the most pressure from both above and below.

They may feel their authority is threatened, have performance KPIs that conflict with project goals, or simply not see the direct benefit for their team amidst their daily fire-fighting. Without their active support, even the best-laid plans will stall.

How to Overcome It:

- Build a Coalition, Not Just a Mandate: Don’t just sell your project to the C-suite. Identify potential champions within middle management who are respected by their peers. Involve them in the planning process, listen to their concerns, and empower them to become advocates for the change within their own teams.

- Speak the Language of Value, Not Just Efficiency: Abstract goals like “improving efficiency” mean little to a manager worried about hitting their quarterly budget. Frame projects in terms that directly address their pain points. Talk about reducing rework that consumes their budget, improving process stability to make forecasting easier, or lowering risks that keep them up at night.

- Train Your Leaders to Be Champions: Effective project champions need more than just authority; they need credible expertise to guide their teams through complex initiatives. Empowering a key leader by having them earn a six sigma black belt certification gives them the deep statistical and leadership tools needed to drive significant results and mentor others.

For creating a broad base of understanding across the entire leadership team, even a foundational six sigma white belt certification can be invaluable for aligning everyone on core concepts and a shared vocabulary.

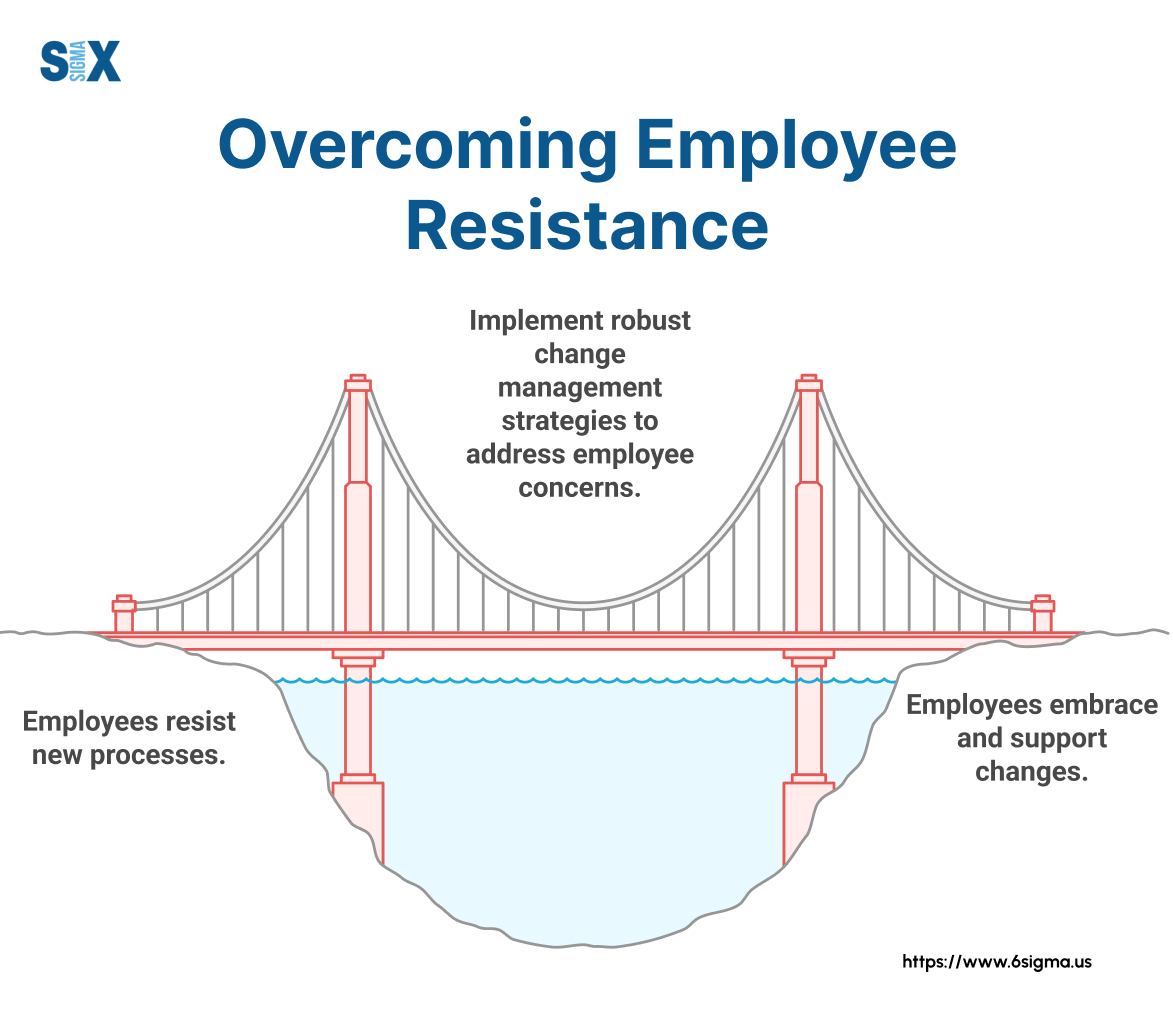

Challenge 2: Employee Resistance & Poor Change Management

One of the most frequently cited challenges of six sigma is employee resistance. But labeling employees as simply “resistant to change” is both unfair and unproductive.

The truth is, that resistance is not a character flaw—it’s a form of feedback. It often points to legitimate, unaddressed concerns: “Will this new process make my job obsolete?” “Will I be able to keep up with these new demands?” “Is this just another flavor-of-the-month initiative that will be abandoned in six months, leaving us to clean up the mess?”

Ignoring these signals is a fatal error. Successfully navigating the challenges with change management in Six Sigma requires treating this resistance as valuable data, not an obstacle to be bulldozed.

How to Overcome It:

- Communicate Early, Often, and Honestly: Don’t let the rumor mill control the narrative. Develop a clear and consistent communication plan that transparently addresses the “What’s in it for me?” (WIIFM) question for every affected group. Be honest about what you know, what you don’t know, and what the goals are.

- Involve, Don’t Just Inform: Change shouldn’t be something that happens to your employees; it should be something that happens with them. Move beyond simple email updates and town halls. Use hands-on workshops and feedback sessions to give employees a genuine voice in redesigning the very processes they work with every day. This co-creation fosters a powerful sense of ownership that top-down mandates can never achieve.

- Diagnose the Fear with Data: Instead of guessing the source of the resistance, diagnose it. Use structured tools to get to the heart of the fear and anxiety driving the push-back. A foundational skill in the Six Sigma toolkit is effective root cause analysis, and it can be applied to human challenges just as powerfully as it is to process defects.

By identifying the true source of the problem—be it fear of job loss, lack of confidence, or process concerns—you can address it directly and build the trust needed for change to succeed.

From People Problems to Profitability

Solving these human-centric challenges is the foundation for achieving real financial returns from your continuous improvement efforts.

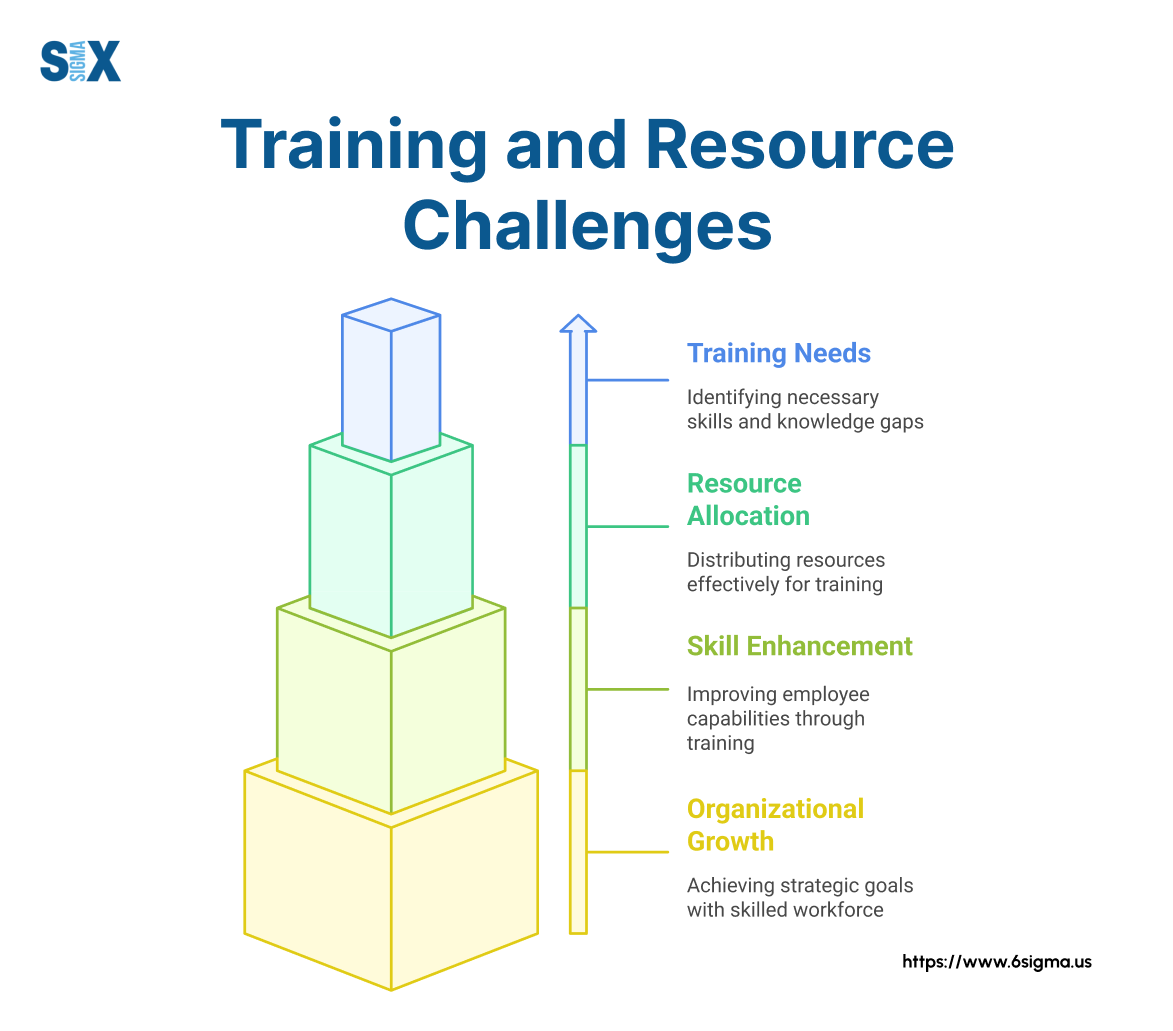

Challenge 3: Inadequate Training and Resource Allocation

When a Six Sigma project fails, a common excuse is that the methodology is “too complex” or “too academic for the real world”.

This thinking misses the point entirely. The challenges in implementing six sigma rarely stem from its complexity, but from a fundamental mismatch between expectations and capabilities.

Organizations ask their teams to execute sophisticated, data-driven projects but fail to provide the necessary training and resources, leading to frustration, flawed analysis, and inevitable failure.

The unspoken truth is that you can’t expect world-class results from an untrained team. Allocating a budget for the project without allocating a budget for capability-building is one of the most common, yet avoidable, pitfalls.

How to Overcome It:

- Implement a Tiered and Targeted Training Strategy: Not everyone on the team needs to be a statistical guru. A successful program builds capability at all levels, ensuring the right people have the right skills for their role. A smart, tiered strategy is the most effective approach:

- For General Employees: Team members who need to understand the basic concepts and participate effectively in projects will benefit greatly from a six sigma yellow belt certification, which provides crucial foundational knowledge.

- For Project Leaders and Key Staff: Individuals tasked with leading projects, analyzing data, and driving results require a deeper skill-set. A comprehensive six sigma green belt certification equips them with the statistical tools and project management framework needed to successfully deliver impactful projects.

- Treat Time as Your Most Valuable Resource: The most frequently overlooked resource is time itself. If project work is treated as an “extra” responsibility on top of an already full workload, it will never get the focus it deserves.

Formally allocate time for project-related tasks and ensure that this work is recognized and valued within the employee’s official role and performance metrics.

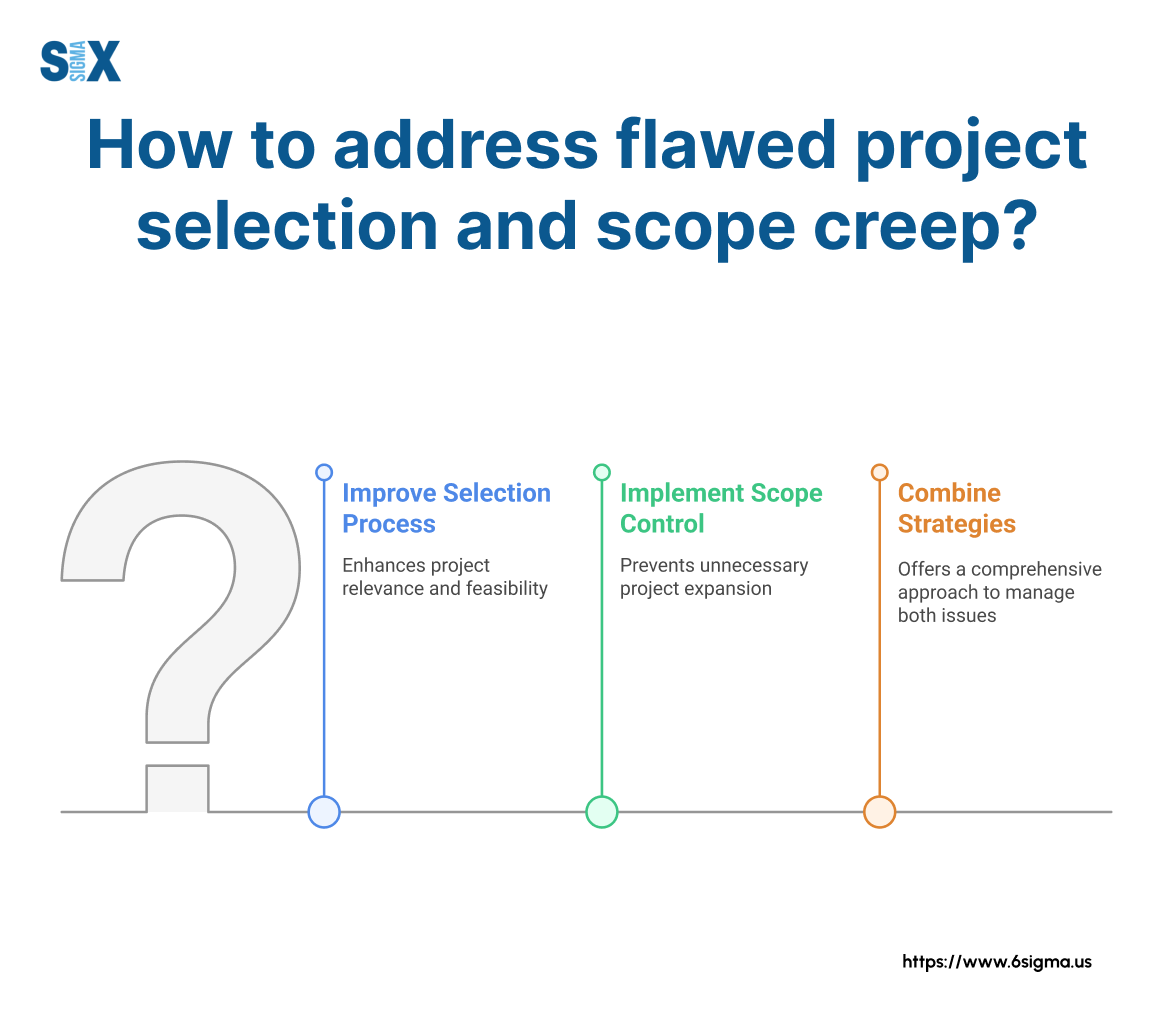

Challenge 4: Flawed Project Selection and Scope Creep

One of the most significant barriers to Six Sigma success occurs before a single data point is even collected: choosing the wrong project.

The common wisdom is to “pick high-impact projects,” but this vague advice often leads organizations down two dangerous paths. The first is the “pet project” trap, where initiatives are chosen based on a senior leader’s intuition rather than objective data, resulting in a project that lacks real ROI.

The second is the “boil the ocean” project, an attempt to solve a problem so massive and ill-defined that the team is doomed to fail from the outset.

A successful Six Sigma program is built on a series of well-chosen, tightly-scoped wins. An early failure caused by poor project selection can drain momentum and erode confidence in the entire initiative.

How to Overcome It:

- Use a Project Selection Matrix: Move from subjective decisions to objective analysis. Develop a simple scoring system or matrix to evaluate potential projects against critical criteria like financial impact, effort required, probability of success, and alignment with overall strategic goals. This data-driven approach ensures you’re investing resources where they will deliver the greatest return.

- Define a Razor-Sharp Scope: Your project charter is your most valuable defense against scope creep. Before the project begins, clearly and explicitly define the start and end points of the process under review. Create a “What’s In / What’s Out” list to leave no room for ambiguity. A tightly defined scope keeps the team focused and makes success achievable.

- Apply Lean Principles First: Not every problem requires a full-scale Six Sigma project. Sometimes, simpler issues can be resolved quickly, building valuable momentum for more complex initiatives. Before committing to a multi-month DMAIC project, consider if foundational tools can deliver a quick win.

Providing teams with a solid Introduction to Lean can often empower them to resolve low-hanging fruit, clearing the way and building the confidence needed to tackle more significant challenges.

Ensure Every Project Drives Real ROI

Choosing the right projects is crucial, but aligning them with a broader profitability strategy is what separates successful programs from failed ones.

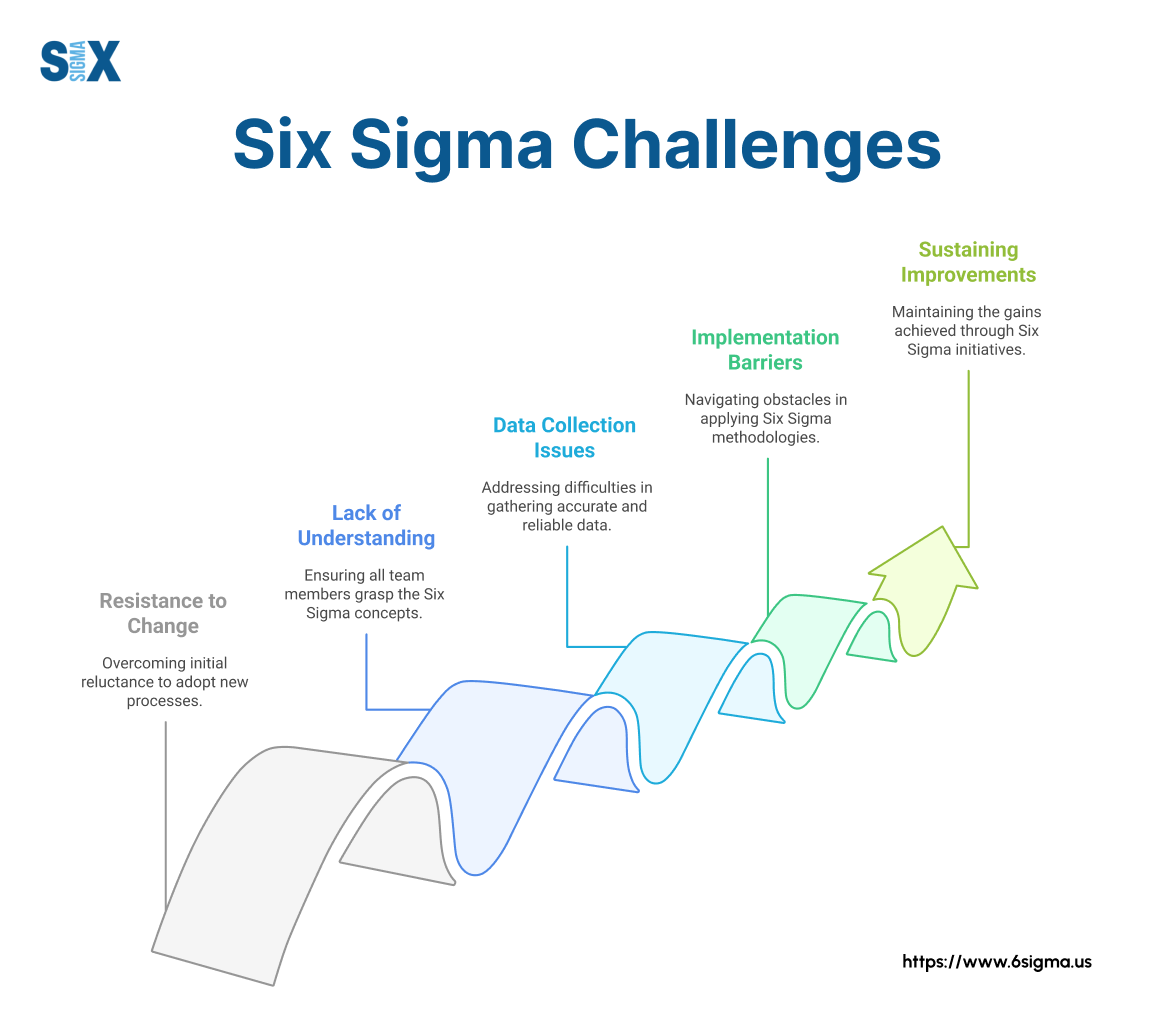

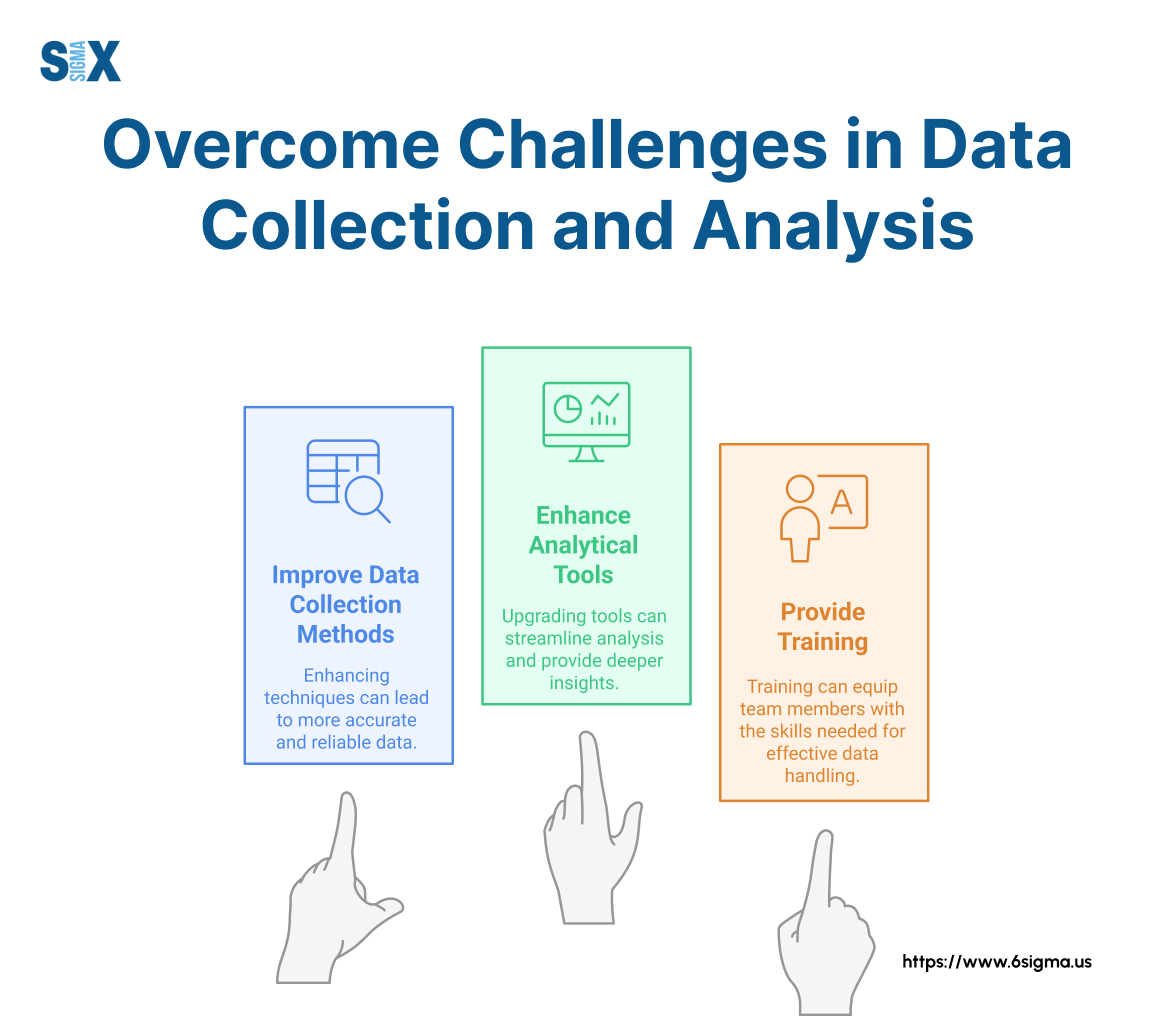

Challenge 5: Difficulty with Data Collection & Analysis

It’s the foundational mantra of any data-driven methodology: “You need good data.” But this simple statement masks a complex and often cultural challenge.

One of the most common challenges in implementing six sigma isn’t the absence of data, but the difficulty in getting clean, honest, and actionable data.

Data problems are rarely technical; they are human. Teams may have powerful incentives to hide or “massage” unflattering data, especially in a culture where numbers are used to assign blame.

Others fall into the trap of “analysis paralysis,” endlessly collecting data and running reports without ever drawing a conclusion or taking action. This is where many promising projects grind to a halt—drowning in data but starved for insights.

How to Overcome It:

- Define Your Metrics Before You Measure: The time to decide what you will measure is in the “Define” phase of your project, not when you’re already swimming in spreadsheets. For every potential metric, ask two simple questions: “What question will this answer?” and “What action will we take based on the answer?” This ensures you only collect data with a clear purpose.

- Create a Culture of “Data Amnesty”: The fastest way to get bad data is to punish people for it. Foster a culture where data is seen as a tool for process improvement, not a weapon for assigning blame. Publicly champion teams that uncover unflattering but honest data, as this is the first step toward real improvement. This psychological safety is non-negotiable for success.

- Empower Teams with the Right Analytical Tools: Collecting data is only half the battle. To drive change, your team must be able to find the story within the numbers. A critical skill is the ability to conduct a thorough root cause analysis, ensuring that you are treating the disease and not just the symptoms.

Team members who have earned a six sigma green belt certification are specifically trained in the statistical tools and analytical methods needed to transform raw, confusing data into clear and actionable insights.

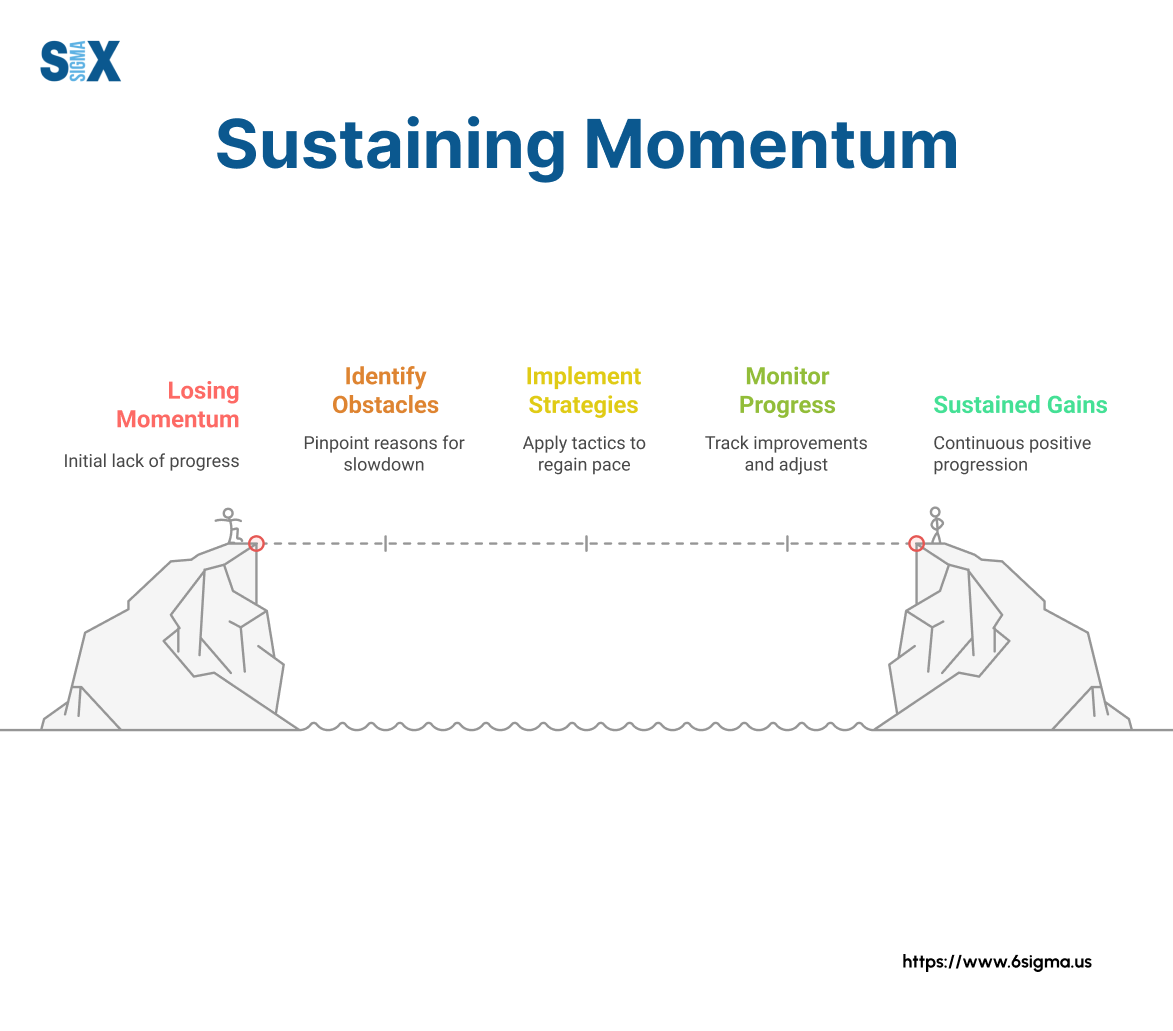

Challenge 6: Losing Momentum & Failing to Sustain Gains

You’ve done it. The project is a success, the final report looks great, and the team has celebrated a hard-fought win. But what happens six months later?

This is where many organizations face one of the most disheartening six sigma challenges: the “rubber band effect.”

The common wisdom says to simply implement a control plan to monitor the new process. While a control plan is essential, it’s often not enough. The unspoken truth is that organizational habits have immense gravity.

Without deliberate, structural reinforcement, processes inevitably snap back to their old, comfortable, and inefficient state. The team’s hard-won gains slowly evaporate, breeding cynicism and making it harder to rally support for future initiatives.

How to Overcome It:

- Standardize, Document, and Automate: The easiest way to do something is the path of least resistance. Your job is to make the new, improved process that path. This means updating all relevant Standard Operating Procedures (SOPs), creating new checklists, and, where possible, changing default settings in software. The goal is to make the old way of doing things harder than the new way.

- Tie the New Process to Performance: If the new process isn’t part of anyone’s official responsibilities, it’s no one’s priority. Embed adherence to the new standards directly into job descriptions and performance reviews for the relevant roles. When maintaining the improvement is part of how a team’s success is measured, it is far less likely to be forgotten.

- Build a Culture of Continuous Improvement: The ultimate way to sustain gains is to make improvement a part of your organization’s DNA. This means moving beyond the mindset of a one-and-done project. By instilling the fundamentals of Lean across the company, you create a culture where everyone is empowered and encouraged to constantly look for the next small improvement.

When continuous improvement becomes a shared value, gains from individual projects don’t just stick—they become the foundation for the next wave of innovation.

Make Your Gains Permanent and Profitable

Sustaining improvements is how one-time project savings evolve into a permanent competitive advantage and a culture of profitability. This requires a dedicated, long-term strategy focused on continuous value creation.

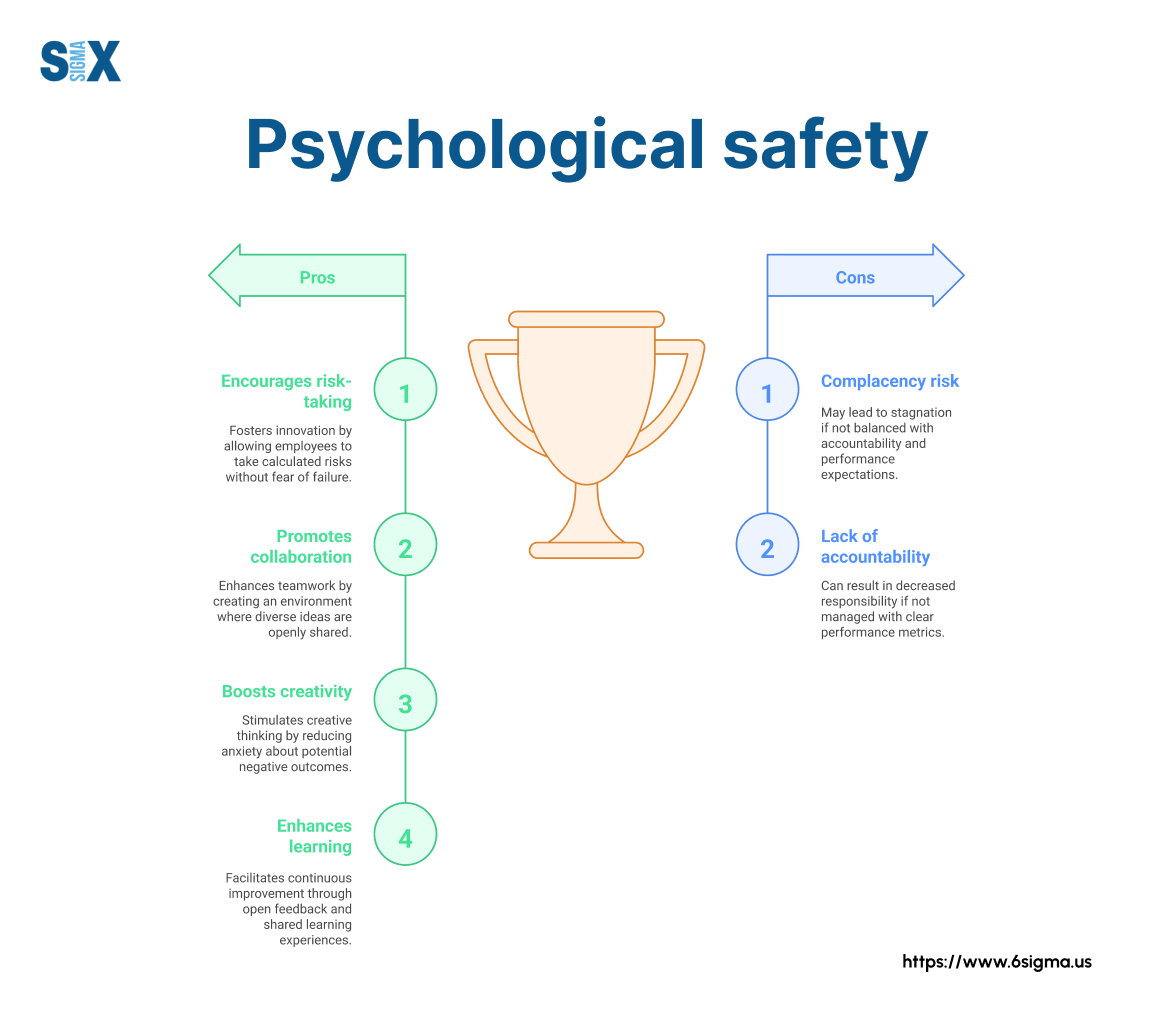

Challenge 7: The Fear of Failure (And How to Cultivate Psychological Safety)

We now arrive at the most powerful and unspoken barrier to successful Six Sigma adoption: the fear of failure. The common wisdom, often misinterpreted from Six Sigma’s focus on perfection, is that we must execute projects flawlessly.

This creates an environment where teams are terrified of making mistakes.

The unspoken truth is that a culture that punishes mistakes will never achieve breakthrough innovation. If employees are afraid to try something that might not work, they will only ever propose safe, incremental changes.

They will shy away from tackling the complex, messy problems where the greatest opportunities for improvement lie. This fear paralyzes creativity and ensures that your organization’s performance will only ever be “good enough,” never truly great.

How to Overcome It:

- Introduce “Pre-Mortems” to Make Risk Safe: A “post-mortem” analyzes a failure after it has happened. A “pre-mortem” does the opposite. Before a project even begins, gather the team and ask them to imagine it has already failed catastrophically one year from now. Then, have them brainstorm all the potential reasons for this failure. This simple exercise flips the script on fear, making it safe and productive to talk about risks proactively.

- Celebrate “Intelligent Failures”: There is a vast difference between a sloppy mistake and an intelligent failure. An intelligent failure is the result of a well-designed, well-executed experiment that produced an unexpected, but valuable, result. When a team takes a smart risk that doesn’t pan out, celebrate the learning that came from it. This sends a powerful message that experimentation is not only allowed but encouraged.

- Lead by Example to Foster Psychological Safety: This cultural shift must be led from the top down. It requires leaders who are confident enough to be vulnerable and who actively coach their teams through ambiguity. A leader who has earned a six sigma master black belt certification is trained to be more than just a technical expert; they are a coach and mentor responsible for fostering the very psychological safety that allows teams to take smart risks, learn from failure, and achieve breakthrough results.

Turn Your Challenges into Competitive Advantages

As we’ve seen, the most significant challenges of six sigma are rarely found in a statistical table; they’re found in meeting rooms, on the factory floor, and in the unspoken fears and motivations of your people.

Overcoming them requires a strategic blend of empathetic leadership, targeted training, and a culture that values honest data and psychological safety above all else.

Tackling these hurdles systematically isn’t just about avoiding project failure; it’s the surest path to unlocking the immense profitability and operational excellence that Six Sigma promises.

The journey to sustainable improvement begins with building capability within your team. A comprehensive six sigma certification program is the most effective and structured way to equip your people with the skills, confidence, and shared language they need to turn these challenges into triumphs.

But you don’t have to navigate this journey alone. If you’re ready to build a resilient, effective, and profitable continuous improvement program that turns these common challenges into your unique competitive strengths, our expert Lean six sigma consultation can provide the strategic guidance and hands-on support you need to succeed.

SixSigma.us offers both Live Virtual classes as well as Online Self-Paced training. Most option includes access to the same great Master Black Belt instructors that teach our World Class in-person sessions. Sign-up today!

Virtual Classroom Training Programs Self-Paced Online Training Programs