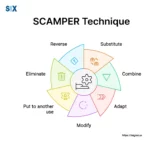

SCAMPER Technique: Drive Innovation & Creativity

SCAMPER presents a principled creativity approach. It encourages out-of-box exploration and perspective flexibility to nourish insight. For progress-seekers committed to cooperation and solutions uplifted through understanding as one, SCAMPER emerges as a trusted companion. Key Highlights What is the SCAMPER Technique? The SCAMPER technique is a powerful creative problem-solving and brainstorming method that organizations across […]