Throughput Time in Manufacturing. Definition, Benefits, and More

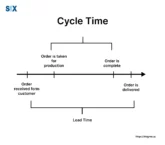

These days, speed and flexibility are everything for keeping ahead of rivals. A major metric companies rely on for measuring and refining performance is throughput time. Also called lead time or cycle time, it’s the full duration needed to complete a process or deliver a product/service to a client — from request received to final […]