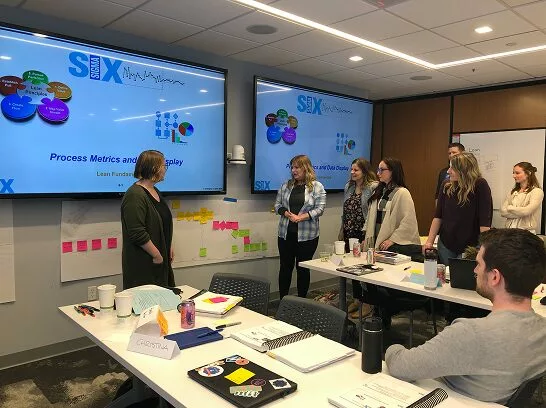

Lean Operations in Manufacturing. Everything to Know

As industries evolve amid dynamic climates, forward-thinking enterprises appropriately prioritize thoughtfully streamlining workflows, judicious resource stewardship, and customer-first mindsets. This evolution birthed lean operations – a collaborative problem-solving structure rooted in jointly eliminating non-value while refining processes equitably. Originating in Toyota’s pioneering model, lean now illuminates diverse domains seeking sustainable excellence. Lean operations’ essence entails […]