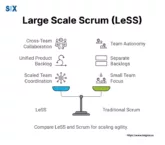

Large Scale Scrum (LeSS): The Ultimate Guide to Scaling Agile

Modern organizations seek ways to take on larger projects and demands by scaling their agile practices. This is where Large Scale Scrum (LeSS) proves key, helping organizations to apply Scrum principles at scale. What is Large Scale Scrum (LeSS)? Large Scale Scrum, aka LeSS, helps scale agile practices across multiple teams, maintaining the core principles […]