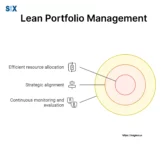

Scaled Agile Framework in Lean. Lean Portfolio Management

Businesses want to get the most value out of the projects they take on while cutting down on waste. This is where lean portfolio management helps – it uses the lean approach to help organizations manage their whole collection of projects and initiatives. Lean portfolio management takes a holistic view of everything. It focuses on […]