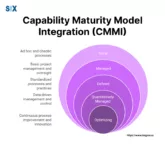

Capability Maturity Model Integration (CMMI): A Guide to Process Improvement

Capability Maturity Model Integration (CMMI) is a process improvement framework that helps organizations enhance their development processes and deliver high-quality products and services. This structured approach combines best practices from multiple disciplines, providing a roadmap for continuous improvement and organizational excellence. CMM focuses solely on software development processes when it emerged in 1987, CMMI expanded […]